A method for realizing eutectic welding of chips

A eutectic welding and chip technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of difficulty in milling and cleaning stainless steel pins, high equipment requirements, and poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

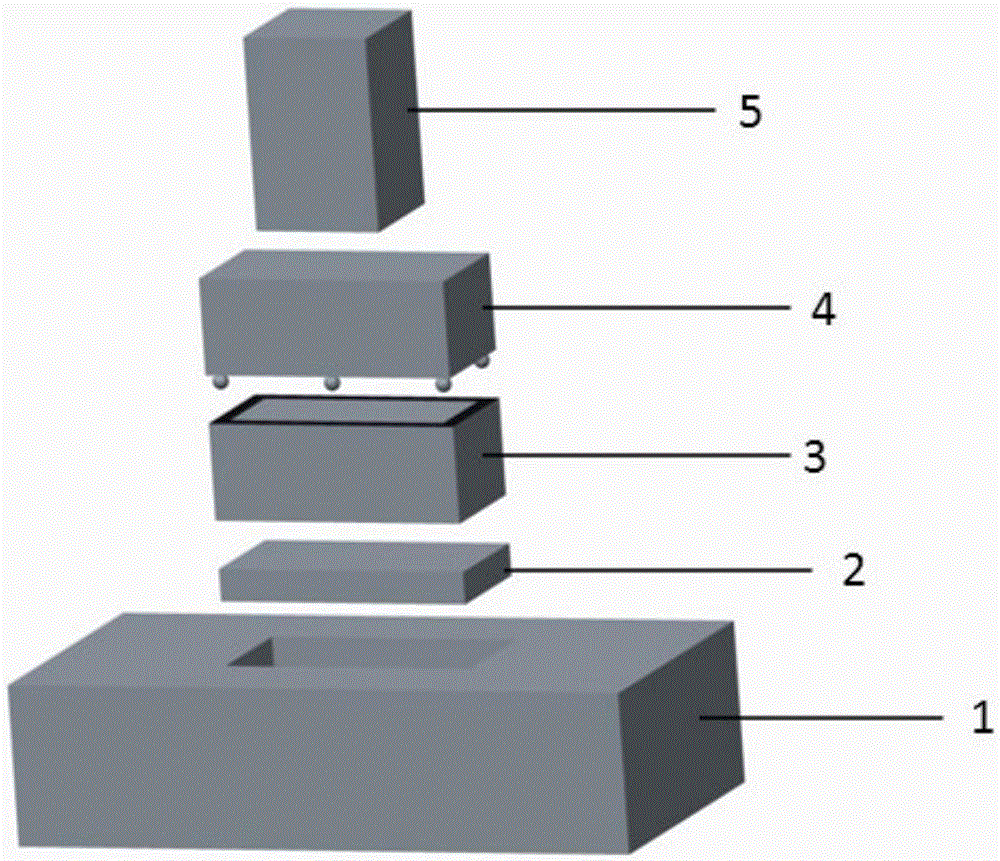

[0031] The purpose of the present invention is to provide a method for providing pressure and positioning for the chip during vacuum eutectic welding of GaAs-based chips, so as to solve the problems that the pressure is not easy to provide and the chip positioning is difficult during vacuum eutectic welding. In order to solve the above problems, the present invention adopts the following technical solutions:

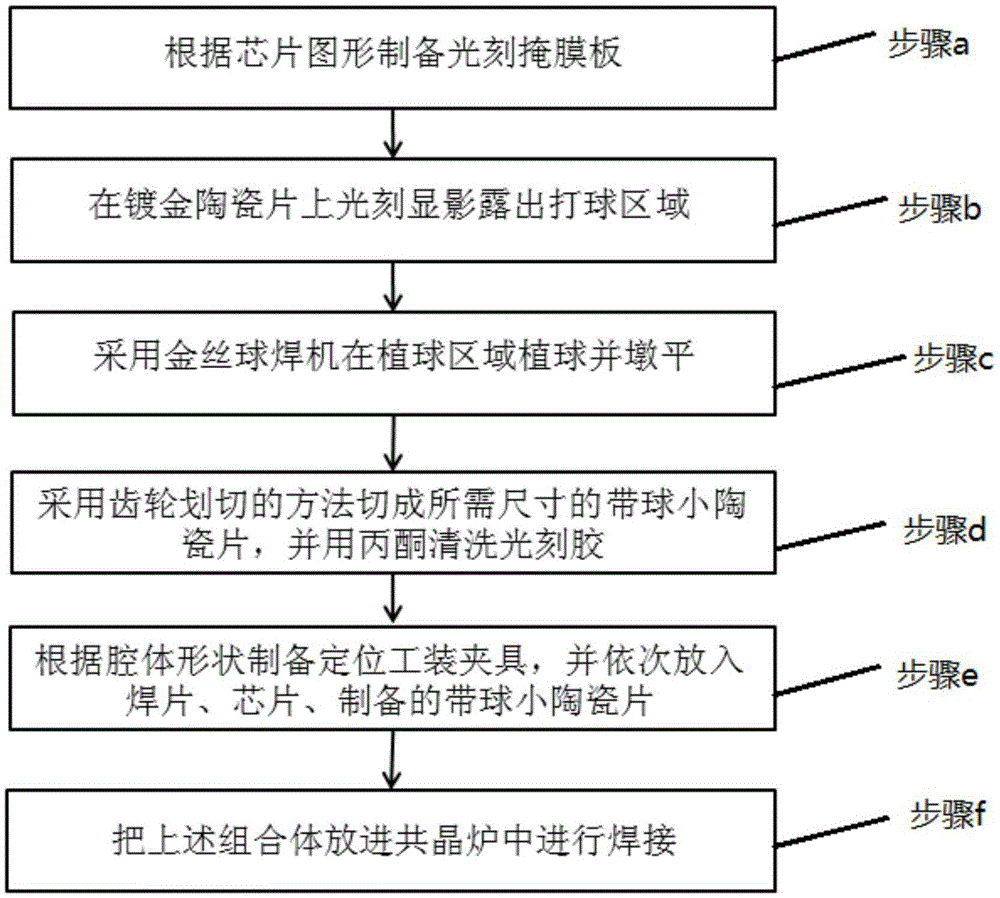

[0032] Step a: Determine the pressable area of the chip according to the pattern of the chip and prepare a photolithographic mask;

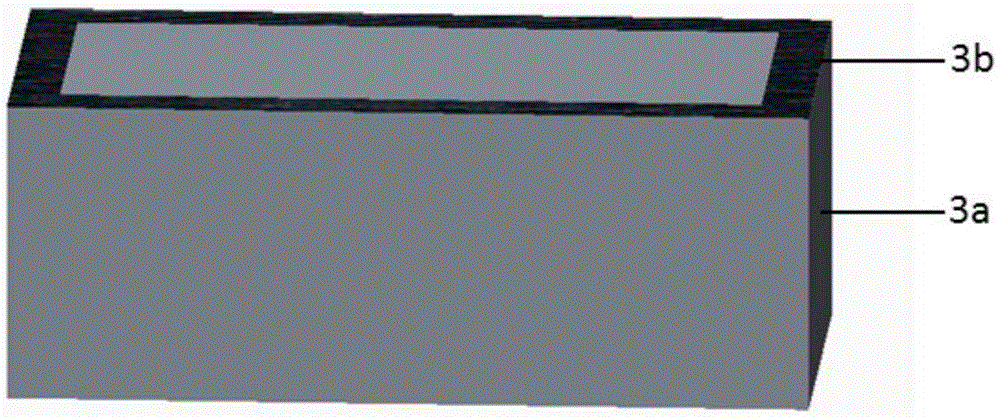

[0033] Step b. Remove the conductive glue in the compressible area of the chip on the gold-plated 3 μm ceramic sheet by photolithography and development, and keep the photoresist in the remaining positions;

[0034] Step c, by means of gold wire ball bonding, plant a ball point on the position where the glue is removed on the ceramic sheet as a bump, the height of the bump is higher than the height of the easily collapsed structure such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com