Flexible packaging composite resin and preparation method thereof

A composite resin and flexible packaging technology, applied in the direction of adhesive type, polyurea/polyurethane adhesive, adhesive, etc., can solve problems such as tunneling, wrinkling, and weak bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

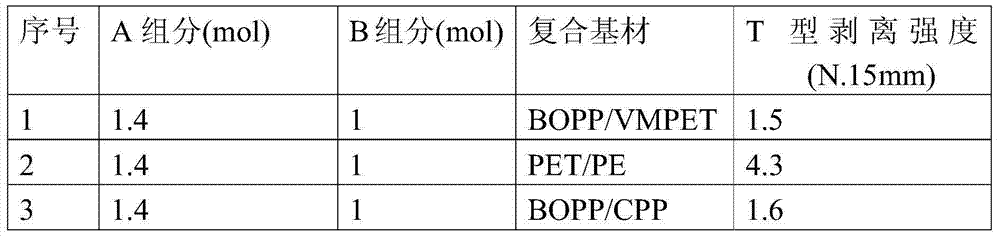

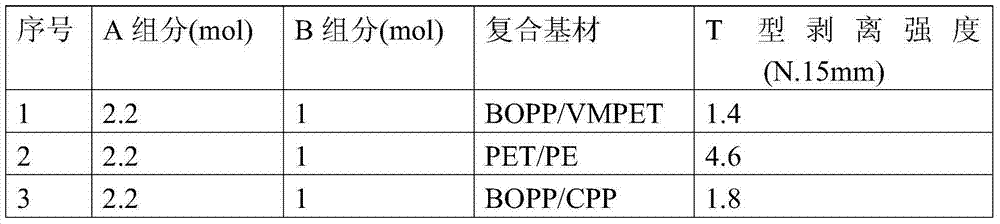

Examples

Embodiment 1

[0024] The preparation method of a kind of flexible packaging composite resin of the present invention is as follows:

[0025] The first step, the preparation of component A:

[0026] Put 1 mol of polyoxypropylene diol in a four-necked flask, dehydrate under the vacuum condition of -0.1Mpa, when the water mass percentage is less than 0.05%, drop to 35°C, add 3.5 mol of HDI and 1 mol of MDI under the protection of nitrogen- 50, raise the temperature to 75±5°C for 3 hours, then raise the temperature to 90°C for 1 hour until the reaction is complete;

[0027] The second step, the preparation of component B:

[0028] Mix 2mol polyester with 1.2mol polytetrahydrofuran evenly.

[0029] Among them, the preparation method of polyester polyol is: in a four-necked flask equipped with a thermometer, a stirrer, a spherical cooler, and a nitrogen-sealed tube, add 600 g of adipic acid, 400 g of isophthalic acid, diethylene di 530g of alcohol, 350g of 1,6 hexanediol and 0.22g of tetrabuty...

Embodiment 2

[0034] The first step, the preparation of component A:

[0035] Put 1 mol of polytetrahydrofuran diol and 0.5 mol of polyoxypropylene triol in a four-neck flask, dehydrate under -0.1Mpa vacuum condition, when the water mass percentage is less than 0.05%, drop to 35°C, add under nitrogen protection 5.3mol of isophorone diisocyanate (IPDI) and 1.7mol of MDI-50, heated to 75±5°C for 3 hours, then raised to 90°C for 1 hour, until the reaction is complete;

[0036] The second step, the preparation of component B:

[0037] Mix 1mol polyester with 1mol castor oil evenly.

[0038] Among them, the preparation method of polyester polyol is: in a four-necked flask equipped with a thermometer, a stirrer, a spherical cooler, and a nitrogen-sealed tube, add 500 g of sebacic acid, 300 g of adipic acid, 1,4-butanedi 230g of alcohol, 380g of 1,6 hexanediol and 0.22g of tetrabutyl titanate catalyst, stir evenly, then slowly raise the temperature to 160°C, control the top temperature to not ex...

Embodiment 3

[0043] The first step, the preparation of component A:

[0044]Put 1.3mol polyoxypropylene diol and 0.5mol tetrahydrofuran-oxypropylene copolyether alcohol in a four-necked flask, dehydrate under -0.1Mpa vacuum condition, when the moisture mass percentage is less than 0.05%, drop to 35°C, in Add 6mol HDI and 2.6mol toluene diisocyanate (TDI) under the protection of nitrogen, raise the temperature to 75±5°C for 3 hours, then raise the temperature to 90°C for 1 hour until the reaction is complete;

[0045] The second step, the preparation of component B:

[0046] Mix 1mol polyester with 1.2mol polyoxypropylene glycol;

[0047] Among them, the preparation method of polyester polyol is: in a four-necked flask with a thermometer, a stirrer, a spherical cooler, and a nitrogen sealed tube, add 410 g of sebacic acid, 500 g of phthalic anhydride, and 1,2 propylene glycol 200g, 520g of 1,6-hexanediol and 0.22g of tetrabutyl titanate catalyst, stir evenly, then slowly raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com