Reaction system for extraction of heated solvent of coal and reaction method

A reaction system and solvent technology, applied in the field of coal chemical industry, can solve the problems of not realizing continuous operation, the solvent cannot pass through, the filter screen is blocked, etc., and achieve the effect of ensuring efficient and continuous operation, low equipment requirements, and easy operation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

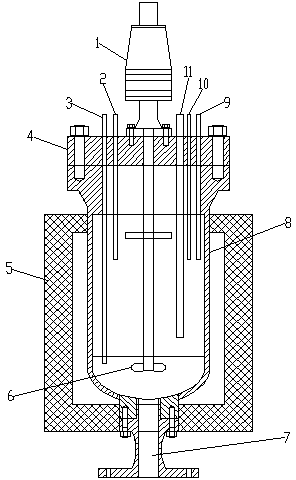

Image

Examples

Embodiment 1

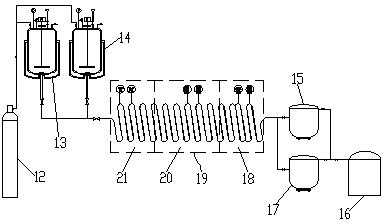

[0043] Embodiment 1: The reaction method used for coal thermal solvent extraction adopts the following specific implementation steps.

[0044] figure 2 Coal is thermally extracted using a circumferential helical tubular reactor 19 as shown. Add 10L of 1-methylnaphthalene to 5 kg of dry coal particles with a particle size of ≤200 μm and dried at 100°C for 20 hours according to the mass-to-volume ratio of coal particles to solvent at 1:2; add the above-mentioned raw materials to the first stirring tank In 13, replace the air in the first stirred tank 13 and the circumferential spiral tubular reactor 19 with nitrogen and fill it with nitrogen to 5 MPa, keep the pressure in the tank and the tube constant within 30 minutes, and then let off the nitrogen. Then fill the first stirred tank 13 with nitrogen to 5 MPa, turn on the stirring and heating switch of the first stirred tank 13, and rapidly raise the temperature to 450° C. under stirring at a speed of 600 r / min. The heating u...

Embodiment 2

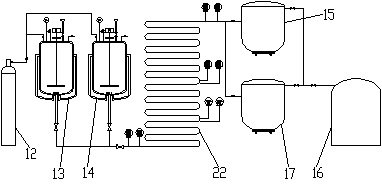

[0045] Embodiment 2: The reaction method used for coal thermal solvent extraction adopts the following specific implementation steps.

[0046] image 3 As shown, the coal is thermally extracted using horizontal reciprocating tubular reactors 22 . Add 3 kg of dry coal particles with a particle size of ≤200 μm and dried at 150°C for 1 hour, and add 18 L of industrial-grade national standard washing oil according to the mass-to-volume ratio of coal particles and solvent to 1:6, and then add it to the first stirring tank 13. Nitrogen replaces the air in the first stirred tank 13 and the horizontally reciprocating tubular reactor 22 and fills it with nitrogen to 5 MPa, keeps the pressure in the still and in the tube constant within 30 minutes, then releases the nitrogen, and then injects nitrogen into the first stirred tank 13 Fill it with nitrogen gas 1Mpa. Open the first stirring tank 13 for stirring, and the rotating speed is set at 100r / min. Turn on the heating device of the...

Embodiment 3

[0047] Embodiment 3: The reaction method used for coal thermal solvent extraction adopts the following specific implementation steps.

[0048] Figure 4 As shown, a vertically reciprocating tubular reactor 23 is used for thermal extraction of coal. Add 1kg of dry coal particles with a particle size of ≤200 μm and dried at 120°C for 10 hours, and add 12L of N-methylpyrrolidone according to the mass-to-volume ratio of coal particles to solvent 1:12. Put the above raw materials into the first stirred tank 13, replace the air in the first stirred tank 13 and the vertically reciprocating tubular reactor 23 with nitrogen and fill it with nitrogen to 5MPa, keep the pressure in the tank and the tube constant within 30min , and then let off the nitrogen. Then fill the first stirred tank 13 with nitrogen to 3Mpa; turn on the stirring and heating switch of the first stirred tank 13, rapidly raise the temperature to 200°C under stirring at a speed of 400r / min, and simultaneously open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com