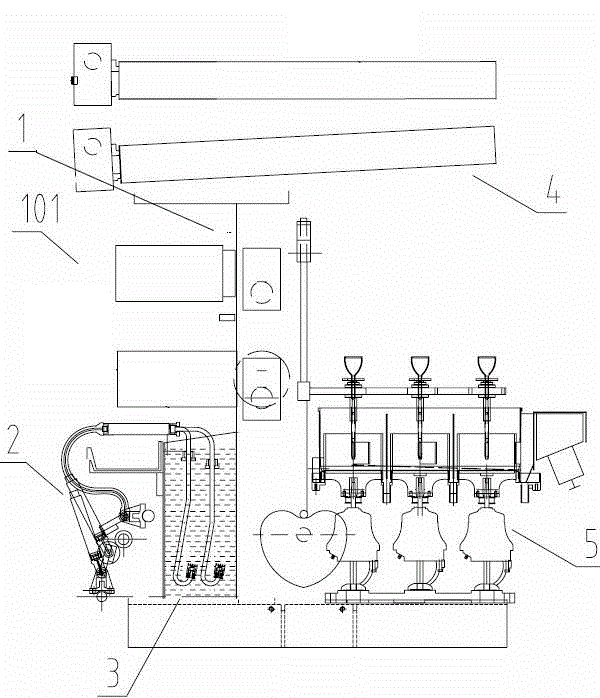

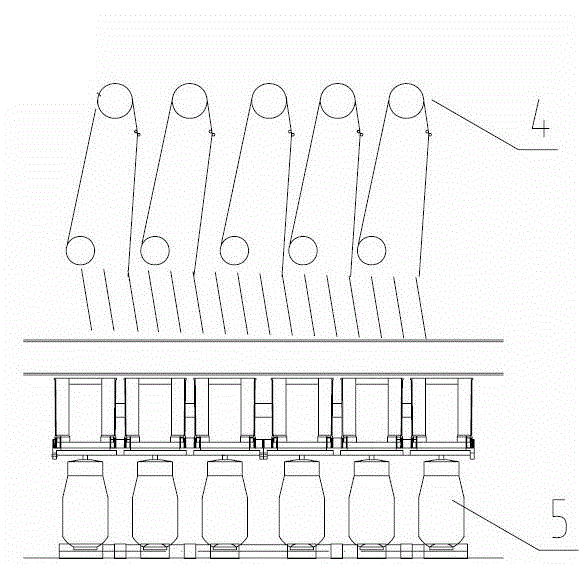

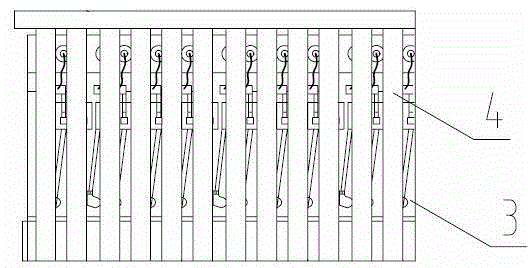

Spinning technology suitable for spinning machine with winding device externally arranged

A technology of a winding device and a spinning process, which is applied to the spinning process field of a spinning machine, can solve the problems of lowering product quality, lowering efficiency, lowering production efficiency, etc. The effect of low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] It is suitable for the spinning process of the spinning machine with the external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0120] A Viscose metering and glue supply

[0121] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.1MPa;

[0122] B Filtration before spinning

[0123] In the pre-spinning filtration process, viscose maturity NH 4 The Cl value is controlled at 7.0ml, the falling ball viscosity is 30mPas, the viscose methyl fiber content is 8.0%, the viscose contains 6.1% alkali, 500ml viscose bubbles are ≤25, the viscose surface tension is 50dyne / cm, and viscose particles below 10μm are ≤100 / ml;

[0124] C filament forming

[0125] In the thread forming process, the composition of the acid bath is: sulfuric acid concentration 135g / L, sodium sulfate concentration 230g / L, zinc sulfate concentration 12g / L, acid bath temperature 55...

Embodiment 2

[0139] It is suitable for the spinning process of the spinning machine with the external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0140] A Viscose metering and glue supply

[0141] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.3MPa;

[0142] B Filtration before spinning

[0143] In the pre-spinning filtration process, viscose maturity NH 4 Cl value is controlled at 13ml, falling ball viscosity is 38mPas, viscose methylcellulose content is 8.1%, viscose contains 5.8% alkali, 500ml viscose bubbles are ≤25, viscose surface tension is 55dyne / cm, viscose particles below 10μm are ≤100 / ml;

[0144] C filament forming

[0145] In the filament forming process, the composition of the acid bath is: sulfuric acid concentration 140g / L, sodium sulfate concentration 240g / L, zinc sulfate concentration 11.0g / L, acid bath temperature 57°C, acid bath surf...

Embodiment 3

[0156] It is suitable for the spinning process of the spinning machine with the external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding,

[0157] A Viscose metering and glue supply

[0158] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.5MPa;

[0159] B Filtration before spinning

[0160] In the pre-spinning filtration process, viscose maturity NH 4 Cl value is controlled at 10ml, falling ball viscosity is 28mPas, viscose methylcellulose content is 8.2%, viscose contains 5.8% alkali, 500ml viscose bubbles are ≤25, viscose surface tension is 53dyne / cm, viscose particles below 10μm are ≤100 / ml;

[0161] C filament forming

[0162] In the filament forming process, the composition of the acid bath is: sulfuric acid concentration 145g / L, sodium sulfate concentration 245g / L, zinc sulfate concentration 12.5g / L, acid bath temperature 56°C, acid bath surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com