Silane paste protective agent and preparation method thereof

A technology of protective agent and silane monomer, which is applied in the field of silane paste protective agent and its preparation, can solve the problems of high product viscosity, insufficient long-term durability, hidden dangers of construction and application, etc., to improve thixotropy and viscosity, and improve waterproof durability Sexuality, the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

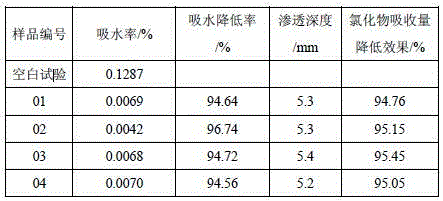

Examples

Embodiment 1

[0039] First add 5.0g of fatty alcohol polyoxyethylene ether MOA-7, 1.0g of polyethylene glycol stearate and 0.5g of polyurethane thickener into 23.5g of water, stir, mix and dissolve at 1000rpm, and then mix and dissolve at 1500rpm Add 40g of isooctyltriethoxysilane and 30g of n-octyltriethoxysilane, and finally drop 0.2g of sodium bicarbonate buffer into the emulsion and emulsify and disperse at a speed of 2000rpm to obtain a uniform white paste shape.

Embodiment 2

[0041] First add 2.0g of sodium lauryl sulfate, 1.5g of polyethylene glycol monolaurate and 0.7g of polyacrylic acid thickener into 15.8g of water, stir, mix and dissolve at 1000rpm, and then add 30g of Propyltriethoxysilane and 50g of n-octyltriethoxysilane were added thereto, and finally 0.4g of sodium acetate buffer solution was dropped into the emulsion and emulsified and dispersed at a rotational speed of 2000rpm to obtain a uniform white paste.

Embodiment 3

[0043]First add 4.0g of alkylphenol polyoxyethylene ether OP-10, 1.2g of glycerol stearate and 1.0g of polyacrylic acid thickener into 27.8g of water, stir and mix and dissolve at 1000rpm, and then mix and dissolve at 1500rpm Add 40g of dodecyltrimethoxysilane and 25g of propyltriethoxysilane, and finally add 1.0g of sodium bicarbonate buffer into the emulsion and emulsify and disperse at a speed of 2000rpm to obtain a uniform white paste .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com