Machining method of multilayer ultrathin diamond blade

A technology of diamond blades and processing methods, which is applied in coatings, electrolytic coatings, cells, etc., can solve problems such as blade quality degradation, blade interlayer peeling, and increased diamond grit detachment probability, so as to reduce equipment investment costs and improve economic efficiency. benefit, realize the effect of layered electrodeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

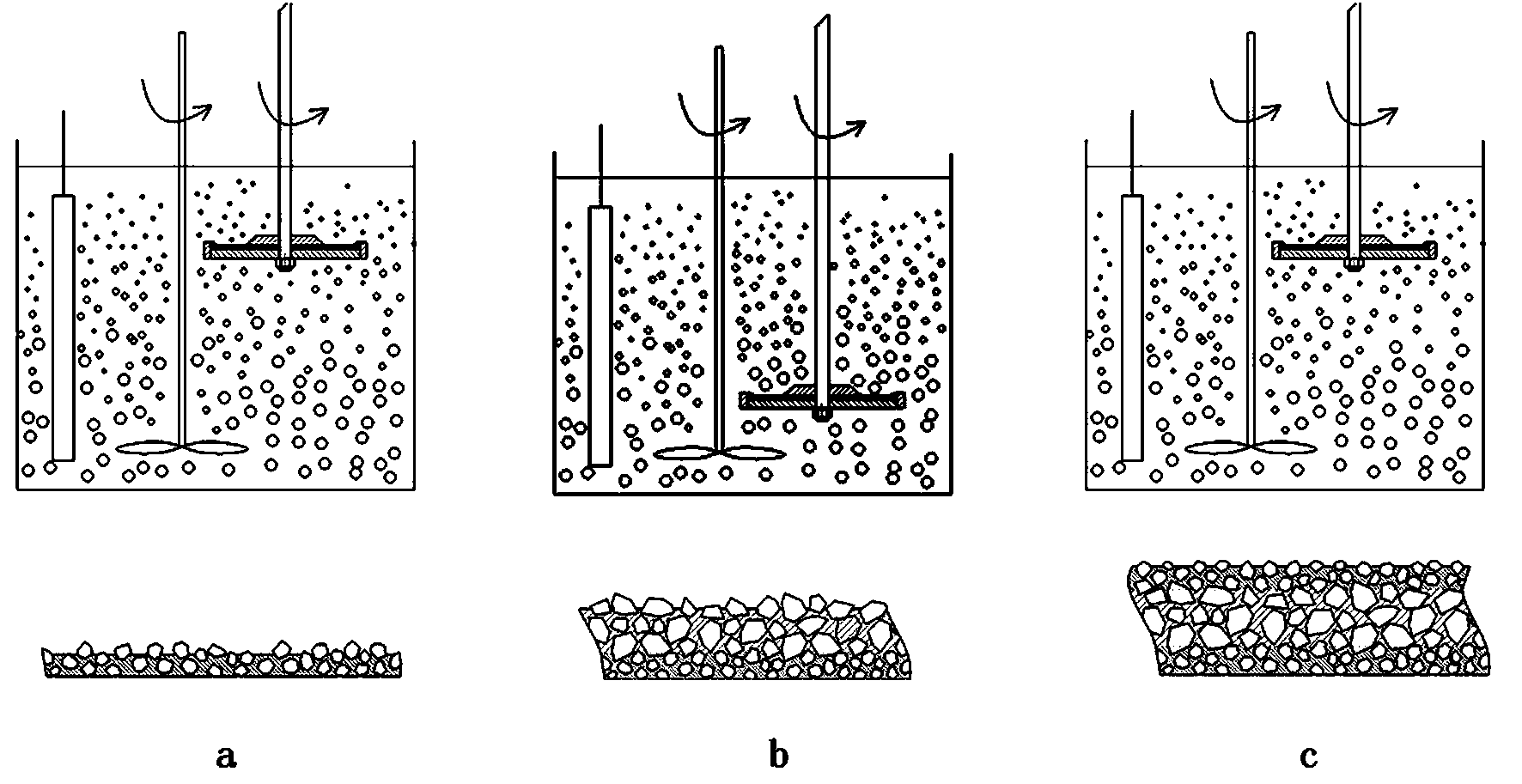

[0031] according to Figure 1~3 The processing method of the multi-layer ultra-thin diamond blade of the present invention is set forth in detail, and the electrodeposition forming method is adopted, and the specific steps are as follows:

[0032] 1) Prepare the electrolyte with 350g / L nickel sulfamate, 10g / L cobalt sulfamate, 10g / L nickel chloride, 20g / L boric acid and 0.6g / L diamond grit with a particle size of 2~10μm. The pH of the solution is 3.5~4.0, and its temperature is kept at 45~50°C.

[0033] 2) The anode substrate 2 is made of electrolytic nickel plate, degreased and activated, and then the anode substrate 2 is connected to the positive electrode of the power supply and placed in the electrolyte, and the agitator 4 is started to stir the electrolyte 3 at a constant speed, and the rotation speed of the agitator is adjusted to make the diamond grit from The electrolytic cell 5 has a gradient distribution from the bottom of the cell to the opening of the notch, and t...

Embodiment 2

[0039] 1) Prepare the electrolyte with 425g / L nickel sulfamate, 25g / L cobalt sulfamate, 25g / L nickel chloride, 35g / L boric acid and 0.8g / L diamond grit with a particle size of 2~12μm. The pH of the solution is 3.5~4.0, and its temperature is maintained at 50~55°C.

[0040] 2) The anode substrate 2 is made of electrolytic nickel plate, degreased and activated, and then the anode substrate 2 is connected to the positive electrode of the power supply and placed in the electrolyte, and the agitator 4 is started to stir the electrolyte 3 at a constant speed, and the rotation speed of the agitator is adjusted to make the diamond grit from The electrolytic cell 5 has a gradient distribution from the bottom of the cell to the opening of the notch, and there is no deposition of diamond grains at the bottom of the cell.

[0041] 3) The current value density is set to 0.4A / dm 2 The cathode substrate 1 is made of an austenitic stainless steel plate with a polished surface, degreased, and...

Embodiment 3

[0044] 1) Prepare the electrolyte with 400g / L nickel sulfamate, 20g / L cobalt sulfamate, 20g / L nickel chloride, 30g / L boric acid and 0.4g / L diamond grit with a particle size of 2~20μm, and electrolyze The pH of the solution is 3.5~4.0, and its temperature is kept at 45~50°C.

[0045] 2) The anode substrate 2 is made of electrolytic nickel plate, degreased and activated, and then the anode substrate 2 is connected to the positive electrode of the power supply and placed in the electrolyte, and the agitator 4 is started to stir the electrolyte 3 at a constant speed, and the rotation speed of the agitator is adjusted to make the diamond grit from The electrolytic cell 5 has a gradient distribution from the bottom of the cell to the opening of the notch, and there is no deposition of diamond grains at the bottom of the cell.

[0046] 3) The current value density is set to 0.3A / dm 2 , the cathode substrate 1 is made of austenitic stainless steel plate with polished surface, degreas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com