Technology for treating coking desulfurization waste liquid by raw gas residual heat

A technology for coking desulfurization waste liquid and waste heat treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, coke oven, etc. The effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

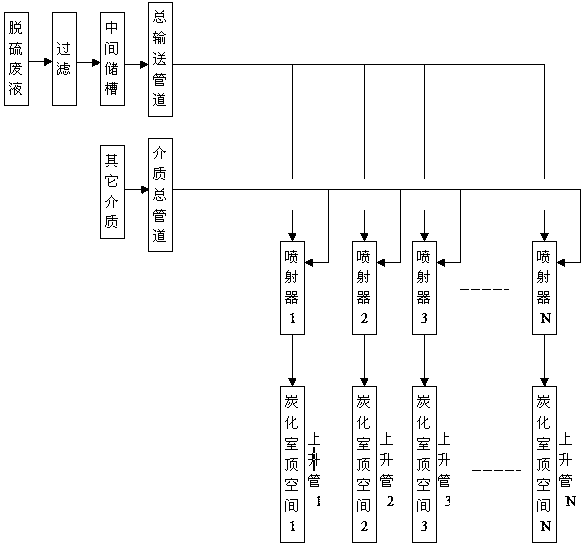

Image

Examples

Embodiment 1

[0048] A process for treating coking desulfurization waste liquid with residual heat of raw coal gas. The desulfurization waste liquid is sent to the desulfurization waste liquid storage tank after being filtered. The filter adopts an open-bag filter, and the mesh number of the filter cloth is 100 mesh. The desulfurization waste liquid storage tank is pressurized and then enters the main desulfurization waste liquid transmission pipeline. The pressure in the total transmission pipeline is 0.7MPa. One hour after the completion of coal charging in the carbonization chamber, the desulfurization waste liquid in the main transmission pipeline starts to pass through the sub-pipelines And the injector is sent to the root of the rising pipe for spraying. The spraying conditions are as follows: the pressure is 0.31MPa, the temperature is 23°C, the flow rate is 68 L / h, and the spraying angle is 52°. At this time, the temperature of the injector sprayed into the high-temperature raw gas a...

Embodiment 2

[0050] A process for treating coking desulfurization waste liquid with residual heat of raw coal gas. The desulfurization waste liquid is sent to the desulfurization waste liquid storage tank after being filtered. The filter adopts an open-bag filter, and the mesh number of the filter cloth is 100 mesh. After the desulfurization waste liquid storage tank is pressurized, it enters the desulfurization waste liquid main conveying pipeline. The pipe and injector are sent to the root of the rising pipe for spraying. The spraying conditions are: pressure 0.55MPa, temperature 62°C, flow rate 92 L / h, spraying angle 52°. At this time, the temperature of the injector sprayed into the high-temperature raw gas area is maintained at about 578°C. After sampling and analysis, the NH in the treated desulfurization waste liquid 4 SCN, (NH 4 ) 2 S 2 o 3 and (NH 4 ) 2 SO 4 The contents were 0g / L, 1.77g / L and 2.35g / L respectively.

Embodiment 3

[0052] A process for treating coking desulfurization waste liquid with waste gas waste heat, adding 12% ammonia water to the desulfurization waste liquid, mixing evenly and then filtering, the desulfurization waste liquid is sent to the desulfurization waste liquid storage tank after filtration, and the filter adopts plate and frame type Filtering machine, the mesh number of the filter cloth is 80 mesh, and the desulfurization waste liquid is pressurized by a high-pressure pump, and then enters the main conveying pipeline of the desulfurized waste liquid. The pressure in the total conveying pipeline is 1.3 MPa. Start to send the desulfurization waste liquid in the main delivery pipeline to the top of the carbonization chamber through the sub-pipelines and injectors for spraying. The spraying conditions are: pressure 0.48MPa, temperature 57°C, flow rate 84 L / h, spraying angle 52 °. At this time, the temperature of the injector sprayed into the high-temperature raw gas area is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com