A large-diameter stainless steel thin-walled tube

A technology for stainless steel and thin-walled pipes, applied in the field of large-diameter thin-walled stainless steel pipes and stainless steel pipes, can solve the problems of poor pressure resistance of white iron chimneys, inconvenient maintenance and replacement, and poor cold resistance, so as to improve mechanical performance and resistance to cold. Corrosion performance, the effect of improving easy deformation and collapse, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

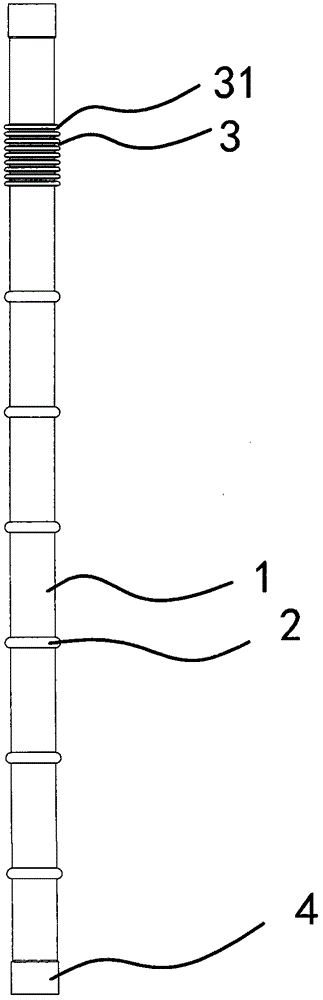

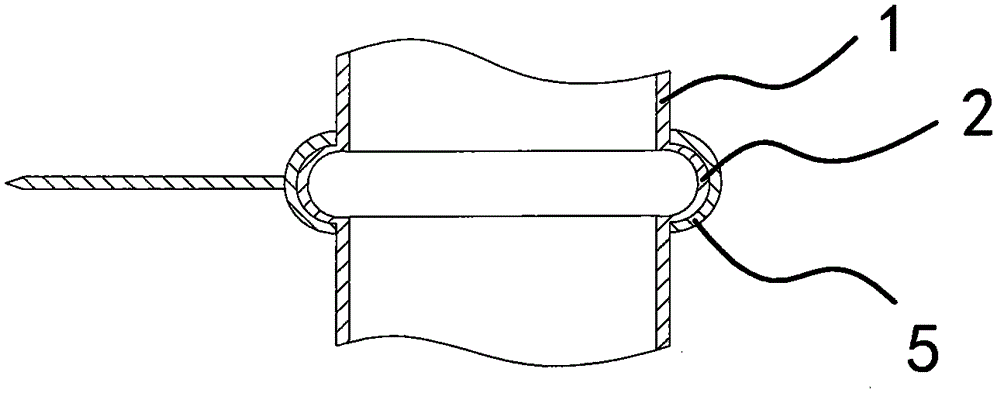

[0050] Embodiment 1: as figure 1 As mentioned above, the large-diameter stainless steel thin-walled pipe is straight and mainly used for rainwater pipes, and can also be used for chimney pipes and wiring pipes.

[0051] Preparation of large-diameter stainless steel thin-walled pipes for rainwater pipes

[0052] Stainless steel with the following composition and mass percentage is selected: carbon (C): 0.02% by weight, chromium (Cr): 18.0% by weight, silicon (Si): 0.8% by weight, manganese (Mn): 0.7% by weight, nitrogen (N): 0.03% by weight, titanium (Ti): 0.4% by weight, niobium (Nb): 0.4% by weight, phosphorus (P): 0.02% by weight, sulfur (S): 0.01% by weight, and the balance is iron (Fe). There are common stainless steel pipe production processes in the art: feeding blanks, calendering, annealing, coiling into pipes, welding, water-cooled cutting, weld seam grinding, and forming to produce large-diameter stainless steel thin-walled pipes for rainwater pipes. Wherein, the r...

Embodiment 2

[0054] Embodiment 2: as Figure 4 As mentioned above, the large-diameter stainless steel thin-walled pipe is L-shaped and is mainly used for wiring pipes, and can also be used for rainwater pipes and chimney pipes.

[0055] Preparation of large-diameter stainless steel thin-walled tubing for wiring ducts

[0056] Stainless steel with the following composition and mass percentage is selected: carbon (C): 0.008% by weight, chromium (Cr): 18.3% by weight, silicon (Si): 0.3% by weight, manganese (Mn): 0.3% by weight, nitrogen (N): 0.05% by weight, titanium (Ti): 0.3% by weight, niobium (Nb): 0.5% by weight, phosphorus (P): 0.022% by weight, sulfur (S): 0.002% by weight, and the balance is iron (Fe). There are common stainless steel pipe production processes in the art: feeding blanks, calendering, annealing, coiling into pipes, welding, water-cooled cutting, weld seam grinding, and forming to produce large-diameter stainless steel thin-walled pipes for wiring pipes. Among them, ...

Embodiment 3

[0058] Embodiment 3: as Figure 5 As mentioned above, the large-diameter stainless steel thin-walled pipe is Z-shaped, and is mainly used for chimney pipes, and can also be used for rainwater pipes and wiring pipes.

[0059] Preparation of large-diameter stainless steel thin-walled pipes for chimney pipes

[0060] Stainless steel with the following composition and mass percentage is selected: carbon (C): 0.01% by weight, chromium (Cr): 18.0% by weight, silicon (Si): 0.39% by weight, manganese (Mn): 0.70% by weight, nitrogen (N): 0.012% by weight, titanium (Ti): 0.5% by weight, niobium (Nb): 0.45% by weight, phosphorus (P): 0.015% by weight, sulfur (S): 0.02% by weight, and the balance is iron (Fe). There are common stainless steel pipe production processes in the art: feeding blanks, calendering, annealing, coiling into pipes, welding, water-cooled cutting, weld seam grinding, and forming to produce large-diameter stainless steel thin-walled pipes for chimney pipes. Wherein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com