Culture medium and method for high-yield production of amylase by ascosphaera apis fermentation

A technology of glomus amylii and a culture medium is applied in the field of culture medium for high-yielding amylase fermented by glosoma melis, can solve the problems of difficulty in industrialization, complicated extraction process and high cost, and achieves good repeatability and high amylase yield. , the effect of short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

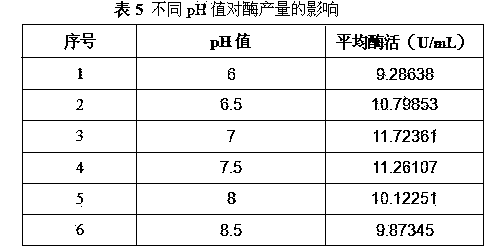

[0019] Single factor experiment to determine the optimal composition of culture medium

[0020] (1) Seed medium preparation: Peel potatoes, cut into pieces, weigh 200g, boil in water for 30min, filter through 6 layers of gauze, weigh 20g of glucose, add distilled water to 1000mL, pH is natural. Autoclave at 121°C for 20min.

[0021] (2) Preparation of seed fermentation liquid: inoculate Ascomonas melii on potato agar medium, culture at 30°C for 3 days, and activate after it produces spores; Bacteria blocks (0.5×0.5 cm) were inoculated into the seed medium, and cultured for 72 hours at 25°C with a rotation speed of 140 r / min, which was the seed fermentation broth.

[0022] (3) The above seed medium was inoculated into a Erlenmeyer flask (250 mL) containing 50 mL of fermentation medium at a 5% inoculum amount, and cultured at 25 °C for 48 h at a rotational speed of 140 r / min.

[0023] (4) Preparation of enzyme liquid: take the fermentation liquid in step (3) and centrifuge a...

Embodiment 2

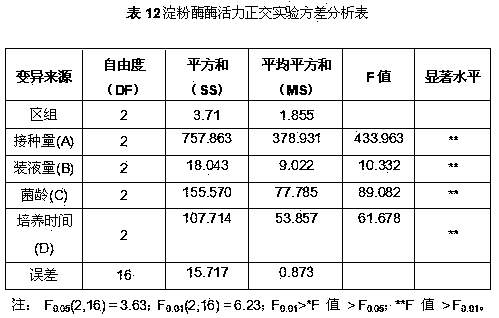

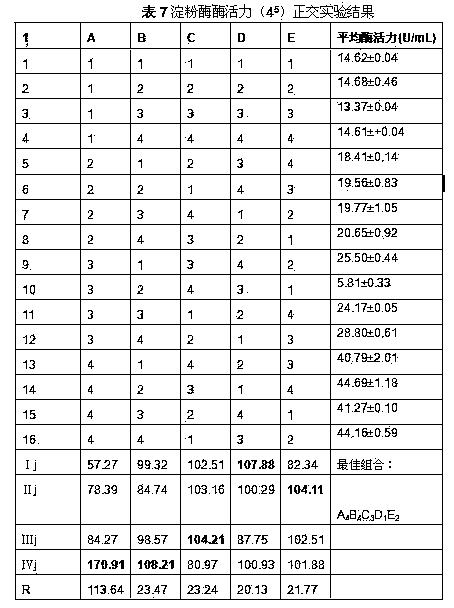

[0044] Orthogonal experiment to determine optimal fermentation conditions

[0045] (1) Orthogonal experiment to determine the best medium

[0046] On the basis of the culture medium determined by the single factor experiment, the concentration of each component and the pH value were changed to prepare different culture medium, and the method was the same as that of steps (1) and (2) in Example 1. See Table 6, inoculate 250mL of the same amount of inoculum (5%) into 250mL of culture solution, and incubate at 25°C for 48 hours at a rotational speed of 140 r / min. Then measure the enzyme activity according to the steps (4) and (5) of Example 1. Select the experimental group number with the optimal result of the orthogonal experiment and the highest enzyme production, and carry out the verification experiment. In order to avoid being cumbersome, the preparation of the culture medium, the preparation of the crude enzyme solution, and the enzyme activity assay method in the emb...

Embodiment 3

[0059] Fungal Amylase Fermentation Method

[0060] (1) Preparation of fermented seeds

[0061] (A) Strain and culture medium

[0062] Bacterial species: Glomus spp. Slant medium: PDA medium

[0063] Liquid seed medium: PDB medium.

[0064] (B) Preparation of seed solution

[0065] Transfer the pure Bacillus palisae on the slope to multiple 250mL Erlenmeyer flasks containing 100mL of culture medium, and then at 25°C (lower temperature fermentation culture is also to inhibit contamination), in reciprocating shaking Cultivate at a bed speed of 140 r / min for 72 hours. When the mycelium grows vigorously and the bacterial liquid becomes viscous, it means that the seeds have grown well.

[0066] In addition, antibiotics can be added to the seed solution before inoculation to kill or inhibit the growth of miscellaneous bacteria, so as to obtain pure strains without miscellaneous bacteria.

[0067] (2) Fermentation culture

[0068] Fermentation medium: optimize the orth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com