High-thermal-conductivity insulation polyester composite material and preparation method thereof

A technology of polyester material and high thermal conductivity filler, applied in the field of polymer processing, can solve the problems of affecting mechanical properties, poor alkali resistance, reducing thermal conductivity of materials, etc., and achieve the effects of improving mechanical properties, stabilizing molecular weight, and improving melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

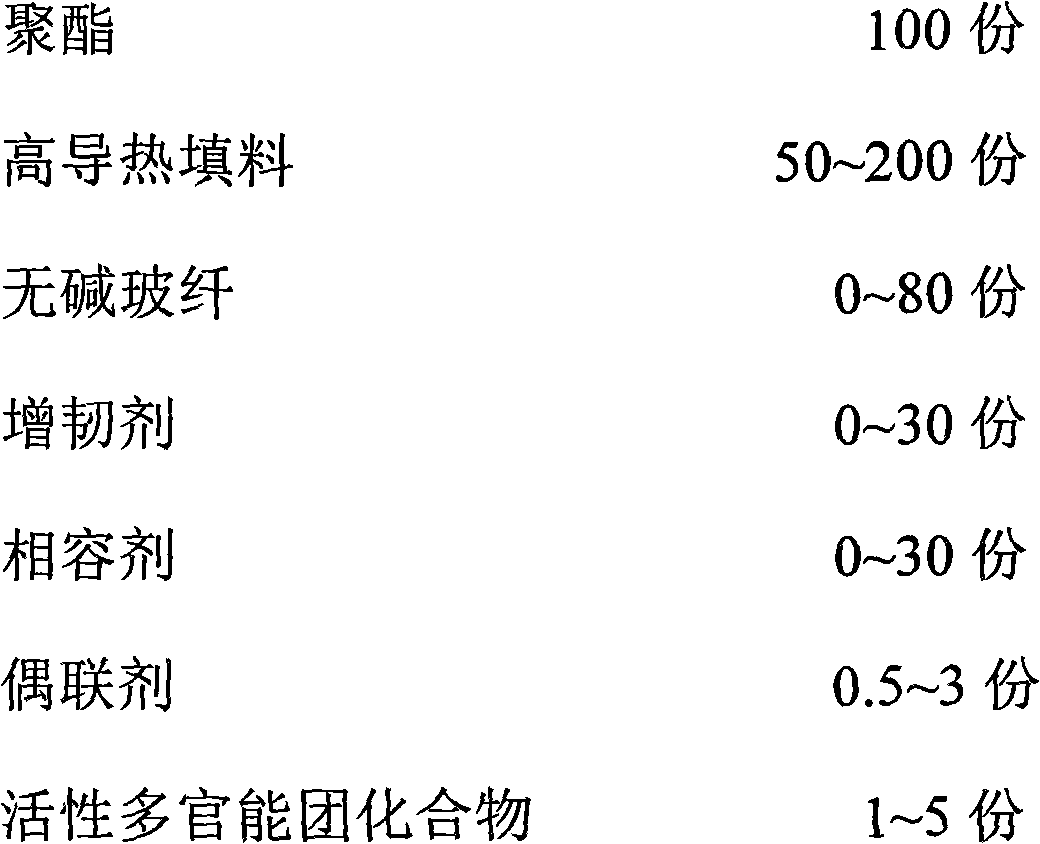

Method used

Image

Examples

Embodiment 1

[0023] Example 1: 100 parts of PET; 150 parts of BN; 20 parts of alkali-free glass fiber; 5 parts of SBS; 10 parts of GMA-g-SEBS; 2 parts of silane coupling agent A172; This example adopts one-step processing. Mix the BN treated with the coupling agent and the dried raw materials according to the above formula, and then extrude and granulate with twin-screw at 270°C. Then inject at 280°C to obtain the product. Product thermal conductivity 1.42W / m·K (vertical direction), volume resistivity 2.75×10 14 Ω cm, surface resistivity 3.84×10 16 Ω cm, tensile strength: 41MPa; notched impact strength: 7.5KJ / m 2 .

Embodiment 2

[0024] Example 2: 100 parts of PBT; 100 parts of alumina; 20 parts of E-glass fiber; 10 parts of PP; 5 parts of SEBS-GMA; 2 parts of A172; 2 parts of SAG008. This example uses two-step processing. Firstly, the aluminum oxide treated with coupling agent, HDPE and SEBS-GMA are evenly mixed, and then pelletized by twin-screw extrusion at 190°C. Then it is uniformly mixed with other components for secondary granulation. Granulation temperature, injection temperature with embodiment one. Product thermal conductivity 0.9W / m K, volume resistivity 1.34E14Ω cm, surface resistivity 3.21E16Ω / cm 2 , tensile strength: 28MPa; notched impact strength: 5.2KJ / m 2 .

Embodiment 3

[0025] Example 3: Take 100 parts of PBT; 40 parts of BN; 60 parts of alumina; 10 parts of SBS; 5 parts of GMA-g-SEBS; 22 parts of silane coupling agent A1722; This example uses two-step processing. First, BN and alumina are treated with a coupling agent, then mixed with SBS and GMA-g-SEBS evenly, and granulated by twin-screw extrusion at 160°C. Then mix it with other components evenly for secondary granulation. Granulation temperature, injection temperature are with embodiment 2. Product thermal conductivity 1.15W / m K, volume resistivity 4.30×10 14 Ω cm, surface resistivity 5.74×10 16 Ω / cm 2 , tensile strength: 35MPa; notched impact strength: 6.3KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com