A compound semiconductor wafer structure

A semiconductor and compound technology, applied in the field of compound semiconductor wafer structure, can solve the problems of electrostatic protection capability limitation, small diode conduction voltage, large wafer area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

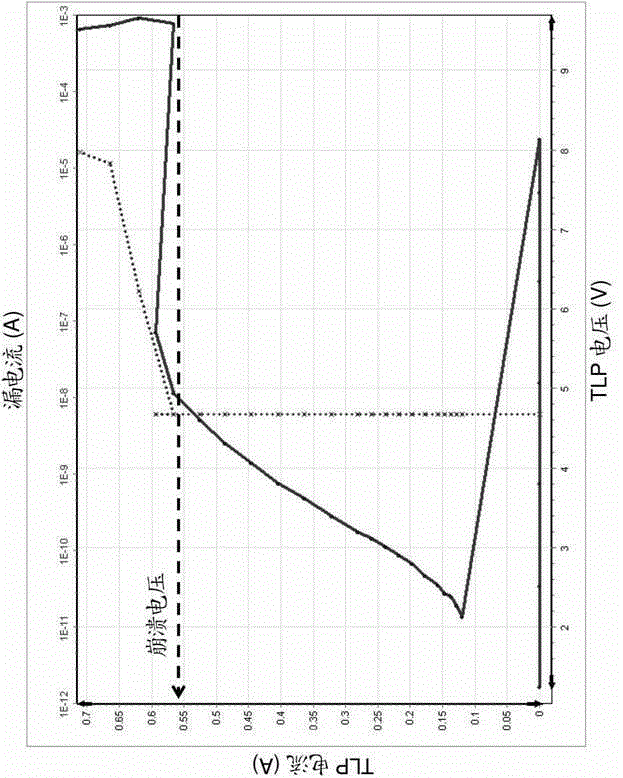

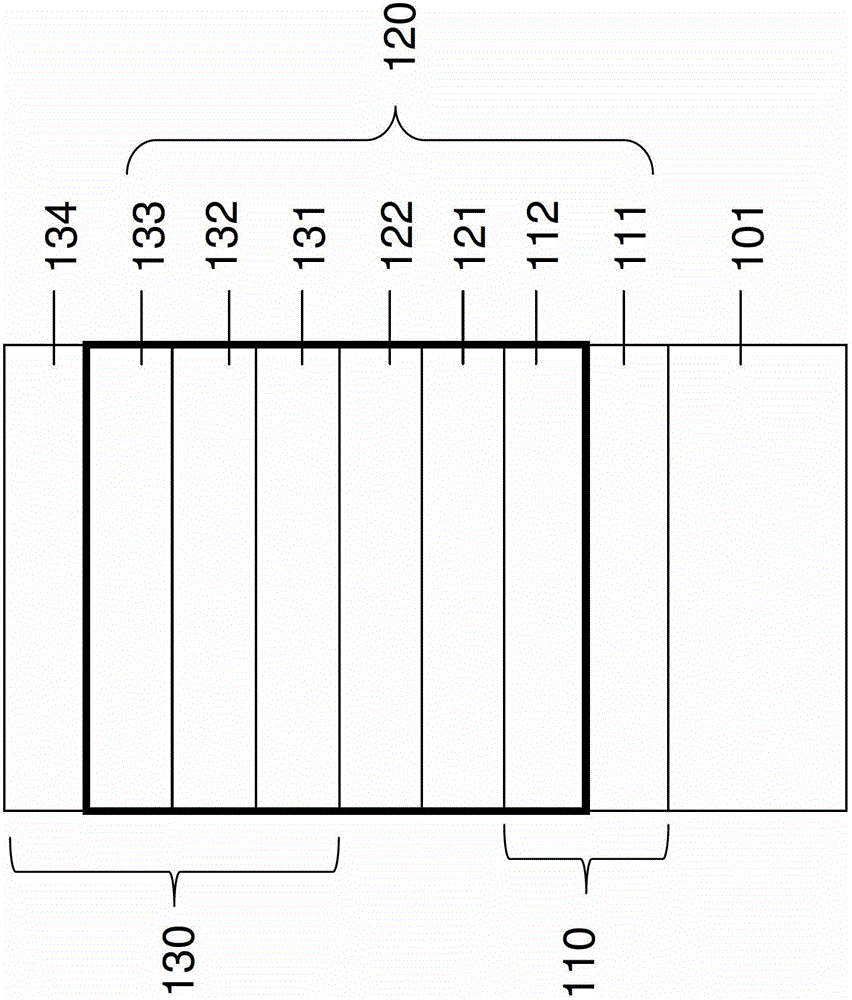

[0024] The compound semiconductor wafer structure integrating the epitaxial structure of a field effect transistor (FET), a heterojunction bipolar transistor (HBT) and a thyristor transistor (Thyristor) provided by the present invention, such as figure 1 As shown, it includes a substrate 101, a field effect transistor epitaxial structure 110, an n-type doped etch stop layer 121, a p-type insertion layer 122 and a heterojunction bipolar transistor structure 130, wherein the substrate 101 The constituent materials can be semi-insulating semiconductor materials such as gallium arsenide (GaAs) or indium phosphide (InP), among which gallium arsenide (GaAs) is preferred; the field effect transistor epitaxial structure 110 is located on the substrate 101 above, including a channel layer 111 and an n-type doped layer 112, wherein the n-type doped layer is located on the channel layer, this structure can be used to make n-type field effect transistors; the n-type doped etch stop layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com