Three-dimensional network aluminum porous body, current collector and electrode each using the aluminum porous body, and nonaqueous electrolyte battery, capacitor and lithium-ion capacitor with nonaqueous electrolytic solution, each using the electrode

A technology of aluminum porous body and three-dimensional mesh, which is applied in the field of three-dimensional mesh aluminum porous body, can solve the problems of electrode loss of conductivity, expensive manufacturing equipment, and high manufacturing cost, and achieve the effect of reducing industrial manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

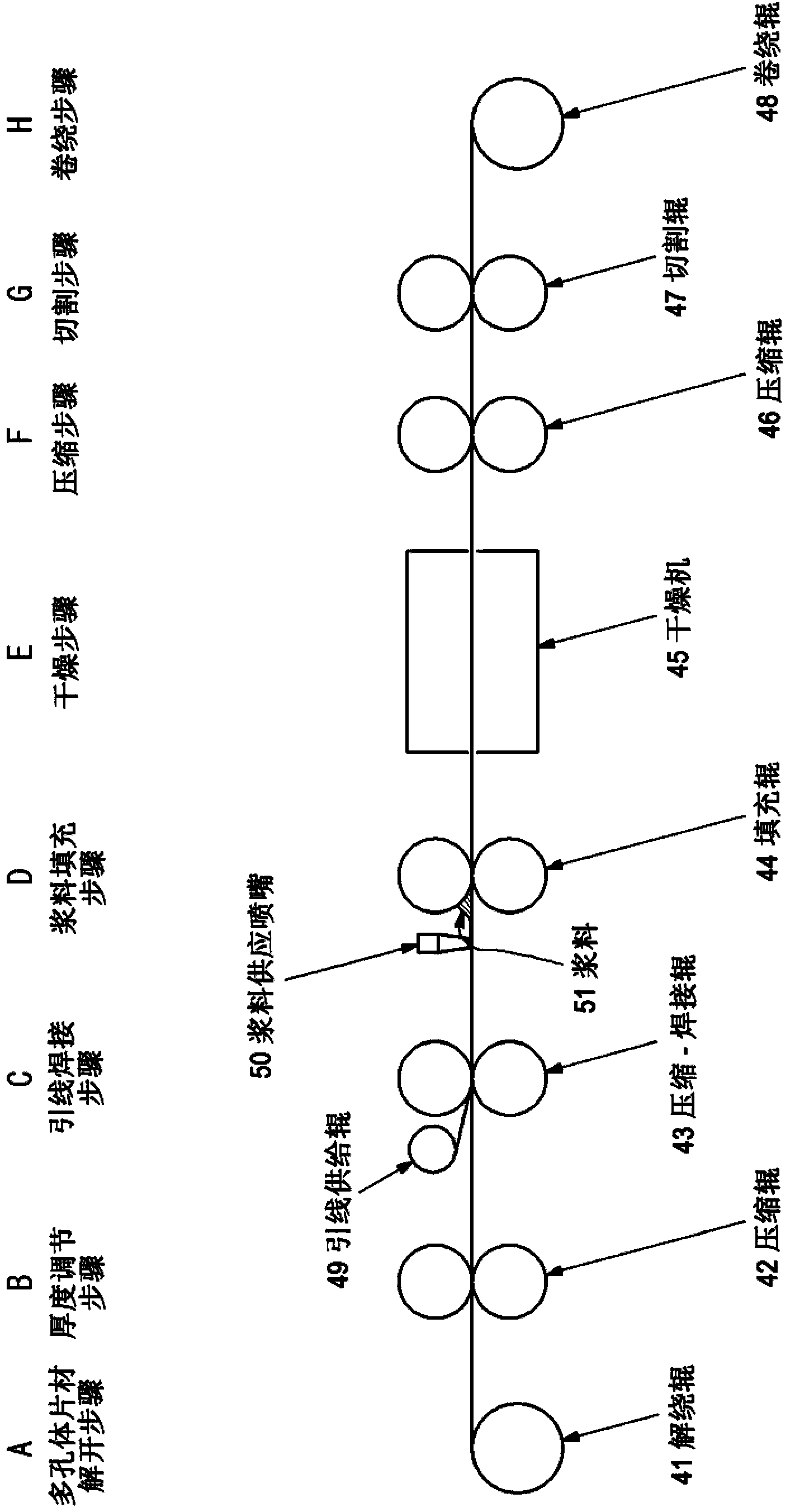

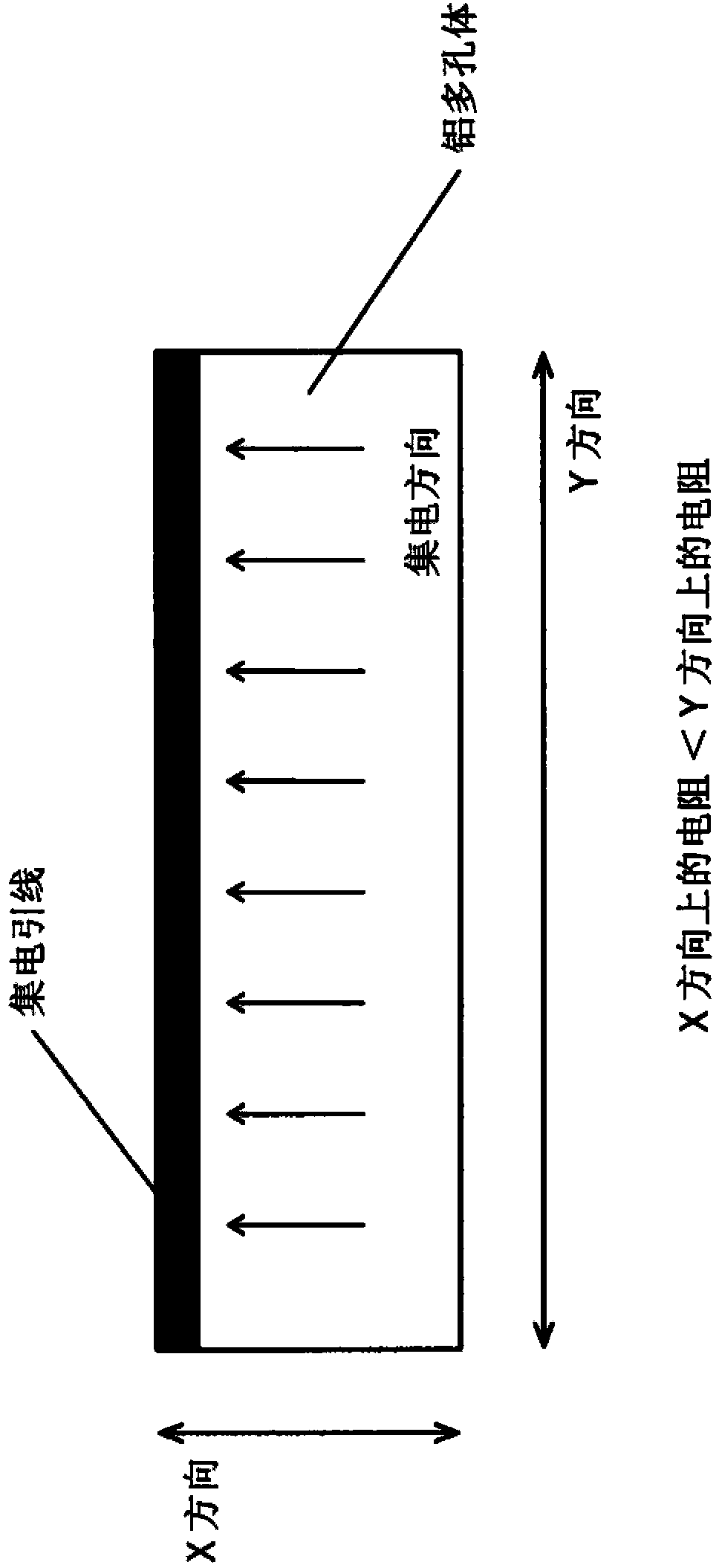

[0065] In the case of continuous fabrication of electrodes, such as figure 1 As shown, electrodes are generally manufactured by a method in which a long sheet-like substrate is unwound from a roll, undergoes a thickness adjustment step, a wire bonding step, an active material filling step, a drying step, a compression step, and a cutting step, and finally Wind it up on a roll. In such an electrode manufacturing method, if it is possible to follow the length direction of the substrate, that is, with figure 1 If the current collector lead is welded in a direction parallel to the conveying direction of the base material in the C step (lead welding step), the continuous productivity of the aluminum porous body will be more excellent. For this reason, it is preferable that the resistance in the width direction perpendicular to the length direction of the substrate is smaller than the resistance in the length direction.

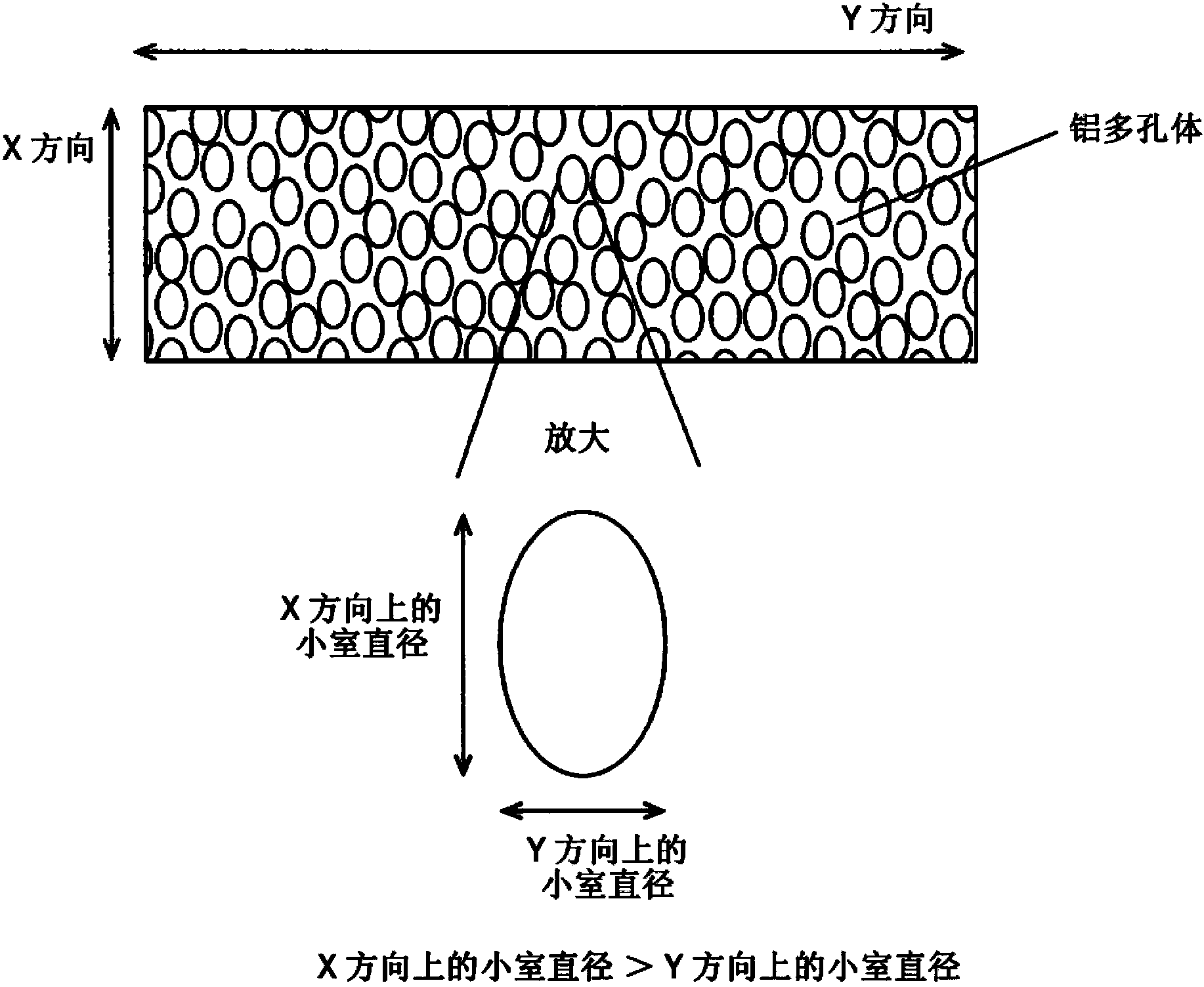

[0066] in such as figure 2 In the aluminum porous body sh...

Embodiment approach 2

[0076] In general, in order to improve output characteristics, electrodes of cylindrical batteries have a structure in which a base material is wound. In the case of producing such an electrode, current collecting leads are provided at ends in the width direction of the substrate to fix a certain length of the substrate (electrode), followed by winding. Therefore, when a long sheet-shaped aluminum porous body is used as an electrode base material, it is desirable that the resistance in the length direction is smaller than the resistance in the width direction.

[0077] in such as Figure 4 In the aluminum porous body shown in which the cell diameter in the Y direction (length direction) is larger than the cell diameter in the X direction (width direction), such as Figure 5 As shown, the resistance in the Y direction (length direction) is smaller than the resistance in the X direction (width direction). Therefore, by using the aluminum porous body as a base material in elect...

Embodiment 1

[0213] (formation of conductive layer)

[0214] As a polyurethane resin molded body, a polyurethane foam having a porosity of 95%, about 50 cells (pores) per inch, a pore diameter of about 550 μm, and a thickness of 1 mm was prepared and cut into 100 mm×30 mm squares. On the surface of the polyurethane foam, the weight per unit area is 10g / m2 formed by sputtering method 2 aluminum film as the conductive layer.

[0215] (Molten Salt Plating)

[0216] Urethane foam with a conductive layer formed on its surface is loaded as a workpiece in a jig with a power supply function, and the jig is placed in a glove box that has been adjusted to an argon atmosphere and low humidity (dew point: -30°C or less) , and immerse the jig in a molten salt aluminum plating bath at a temperature of 40°C. At this time, two rolls were placed in the form of an inverted letter V with respect to the workpiece, molten salt plating was performed while increasing the width of the workpiece, and a tension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com