Powdery difficult-separation low-grade iron ore multistage fluidized magnetic roasting furnace and roasting method thereof

A magnetic roasting and low-grade technology, applied in the field of metallurgy, can solve the problems of uneven roasting cost of iron ore reduction, slow reduction process, uneven ore reduction, etc., to achieve flexible atmosphere control, increased gas-solid contact area, and furnace The effect of large temperature adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

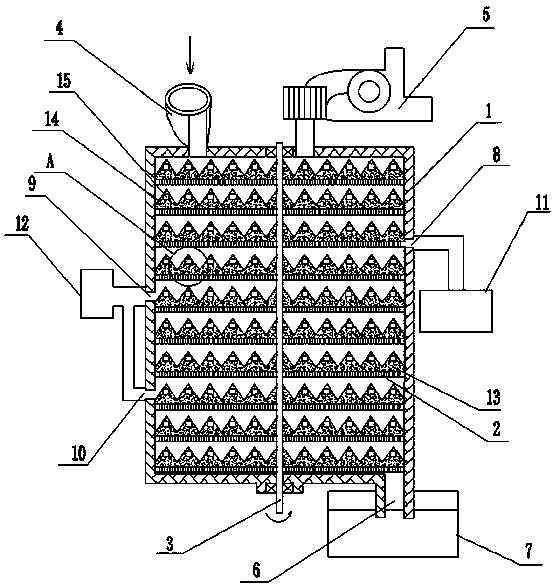

[0035] Such as figure 1 and 2As shown, a multi-stage fluid magnetization roasting furnace for powdery refractory low-grade iron ore comprises a cylindrical body of furnace 1, and body of furnace 1 is provided with several partitions 2 (in this embodiment, partitions 2 are 10 layer), the center of the furnace body 1 is pierced with a rotating shaft 3, the upper and lower ends of the rotating shaft 3 are respectively fixed to the furnace body 1 through bearings (not shown in the figure), and the top of the furnace body 1 is provided with a feeding port 4 and an induced draft fan 5 , the bottom of the furnace body 1 is provided with a discharge port 6, and the upper, middle and lower parts of the furnace body 1 are sequentially provided with a first smoke inlet 8, a second smoke inlet 9 and a third smoke inlet 10; A pool 7 is provided; the dividing plate 2 is provided with a grill arm 13, and the grill arm 13 is connected with the rotating shaft 3; the grill arm 13 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com