A Method for Inhibiting Cohesion Loss in Pressurized Fluidized Reduction of Iron Ore Powder

A technology of coagulation loss and iron ore powder, which is applied in the field of suppression of cohesion loss during pressurized fluidized reduction of iron ore powder, can solve the problem of continuous operation of the process, low reduction rate, reduction speed and low production efficiency To achieve the effect of avoiding mutual hooking and agglomeration, increasing the gas-solid contact area, and accelerating the gas-solid reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, a method for suppressing cohesion loss when pressurized fluidized iron ore powder is reduced, the iron ore powder is mixed with an anti-adhesive agent to obtain a reaction mixture, the anti-adhesive agent is waste plastic, and the plastic powder is polystyrene. Ethylene; put the reaction mixture into the fluidized reaction device, and feed N into the fluidized reaction device at a temperature of 800-900°C 2 Or inert gas, iron ore powder and anti-sticking agent are mixed, wrapped, and pre-cracked in the fluidized reaction device; then the reduction pressure of the fluidized reaction device rises to 0.15-0.30MPa, and the fluidized reaction device cools down to 700-750°C. And filling the reducing gas into the fluidization reaction device to carry out the fluidization reduction of the iron ore powder, and the waste plastics are non-chlorine energetic plastic powders. The detailed description is as follows:

[0045] Step 1: Mix iron ore powder with anti-...

Embodiment 2

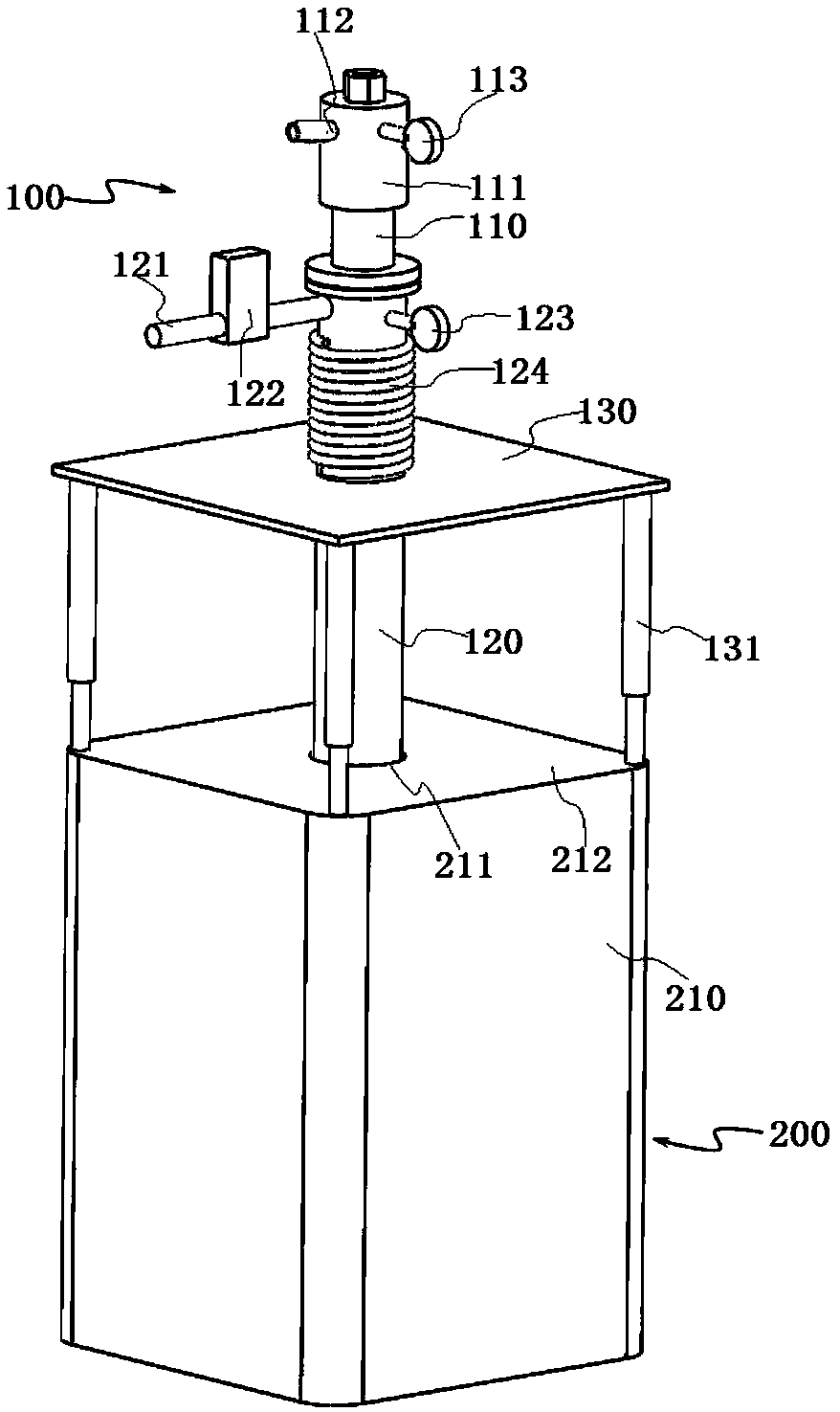

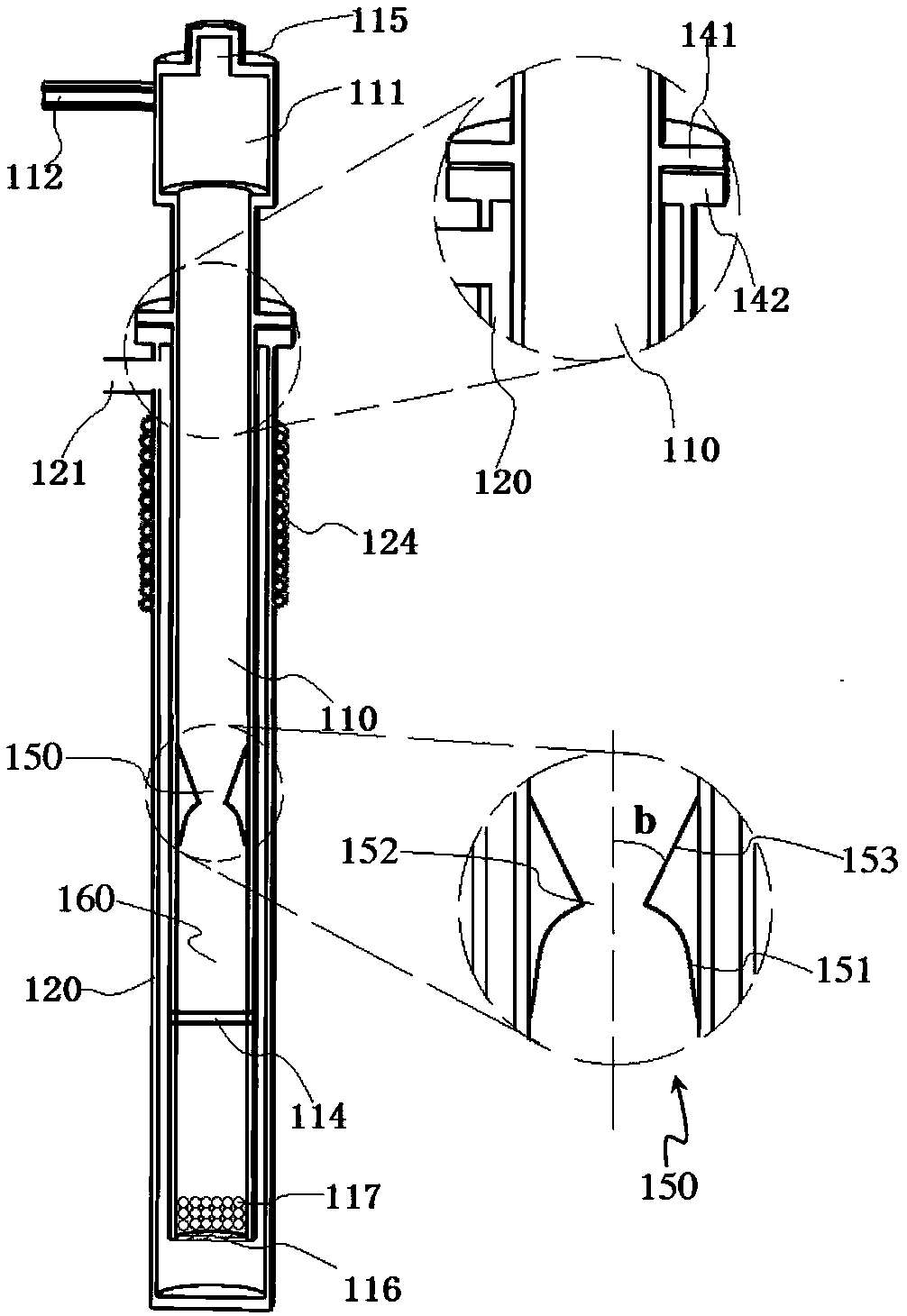

[0067] The basic content of this embodiment is the same as that of Embodiment 1, the difference is that: before the wrapping reaction chamber 160 is pushed to the high constant temperature range of 800-900°C, the top of the reaction inner tube 110 is first added with a reaction mixture including iron ore powder and anti-sticking agent material, and blow He gas into the outer casing 120, and the gas flow rate is 0.3-0.5m / s, preferably 0.3m / s, He gas enters the reaction inner tube 110 from the outer casing 120 through the bottom of the outer casing 120 , and push the wrapped reaction chamber 160 of the double-layer tube reaction unit 100 to a low constant temperature range of 300-350°C, the gas drives the reaction mixture to roll in the wrapped reaction chamber 160, and under the action of the air flow guide section 153, the air flow is Cyclical disturbances occur in the wrapping reaction chamber 160, and He gas is blown intermittently to avoid delamination of the anti-adhesive a...

Embodiment 3

[0069] The basic content of this comparative example is the same as that of Example 1. During the reduction process, the pressure of the reaction inner tube 110 was 0.3 MPa, and the reduction time was 50 minutes. No bonding occurred, and the metallization rate was 83.21%. During the reduction process, the anti-sticking agent forms uniform graphite or adhering carbon on the surface of iron ore powder, so as to avoid iron whiskers or iron atoms from interlocking and agglomerating each other, and avoid particle cohesion.

[0070] Example 3

[0071] The basic content of this comparative example is the same as that of Example 1. During the reduction process, the pressure of the reaction inner tube 110 is 0.2 MPa, and the reduction gas contains CO mixed gas, and the mixed gas is 70% CO + 30% N 2 , the reduction time is 40 minutes, no bonding phenomenon occurs, and the metallization rate is 83.05%.

[0072] The anti-sticking agent includes plastic powder, silicon nitride powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com