A method for iron ore fluidized reduction ironmaking

A technology of fluidization and iron ore powder, which is applied in the direction of fluidized bed furnaces, furnaces, furnace types, etc., can solve problems such as difficult implementation, difficult control, and difficult control of carbon-attached process conditions, so as to achieve easy implementation and inhibit sticking Loss of flow, the effect of increasing the metallization rate of pre-reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

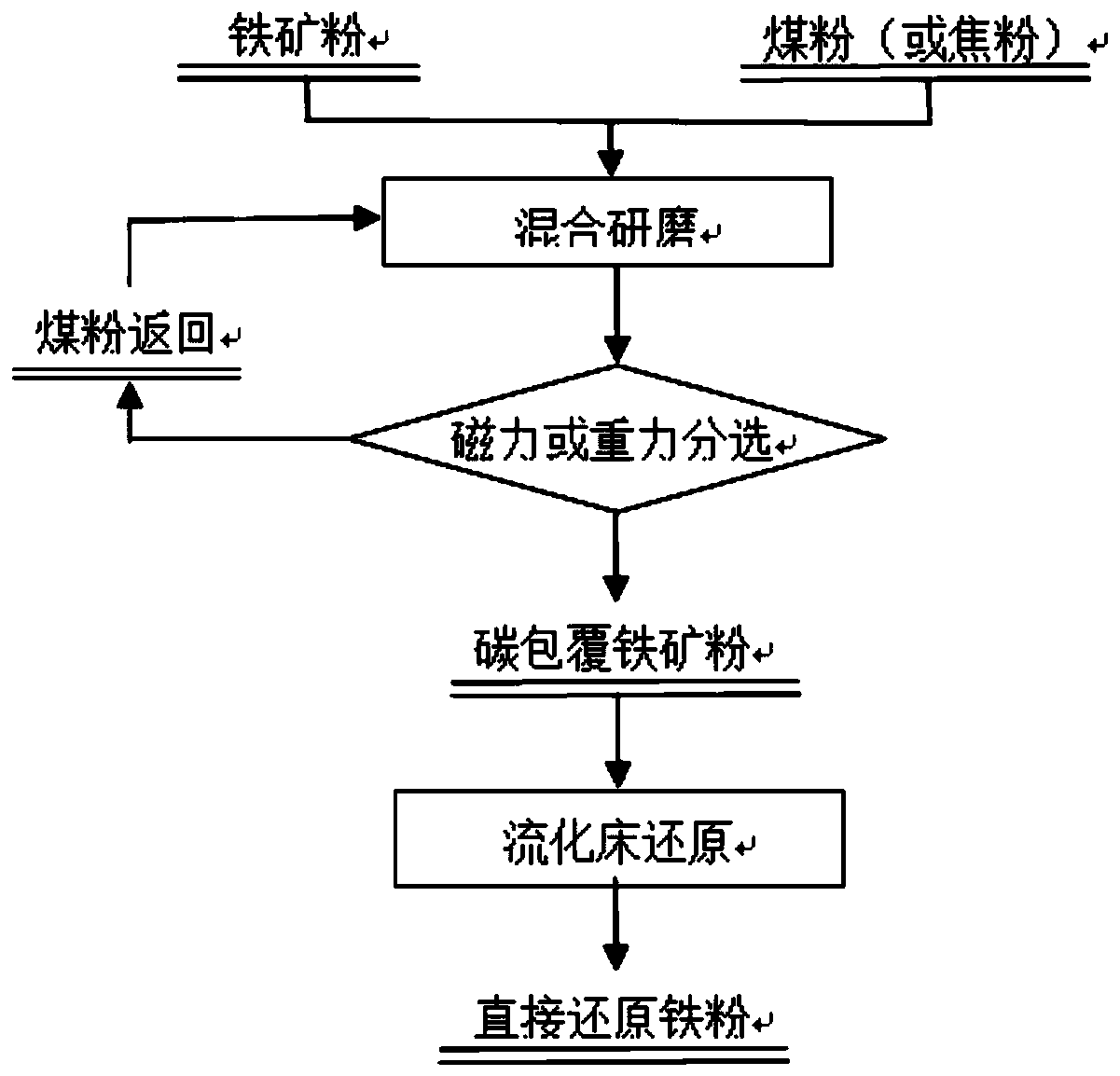

[0025] (1) Put the magnetite powder and anthracite powder less than 1.0mm into the ball mill and grind for 20 minutes.

[0026] (2) Then the iron ore powder is separated by magnetic separation to obtain coal powder coated iron ore powder.

[0027] (3) Add coal powder coated iron ore powder into the fluidized bed, and at 850°C, feed CO=40%, H 2 =10%, N 2 =50% mixed gas, fluidized reduction for 60 minutes.

[0028] Results No cohesive flow loss occurred in the fluidized bed, no iron whisker was found in the sample after reduction, and the metallization rate was 85.7%.

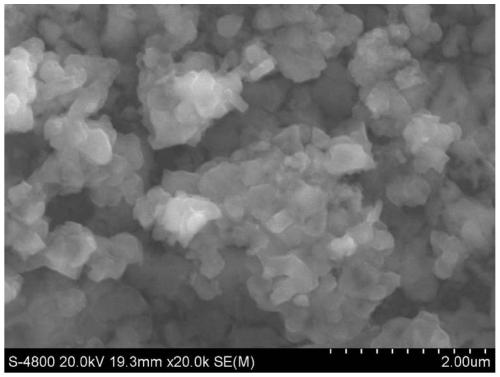

[0029] Electron microscope scanning was carried out to the obtained sample, and the results can be found in image 3 , image 3 For the iron that the method reduction that the embodiment of the present invention provides provides, by image 3 It can be seen that there is no iron whisker in the sample.

Embodiment 2

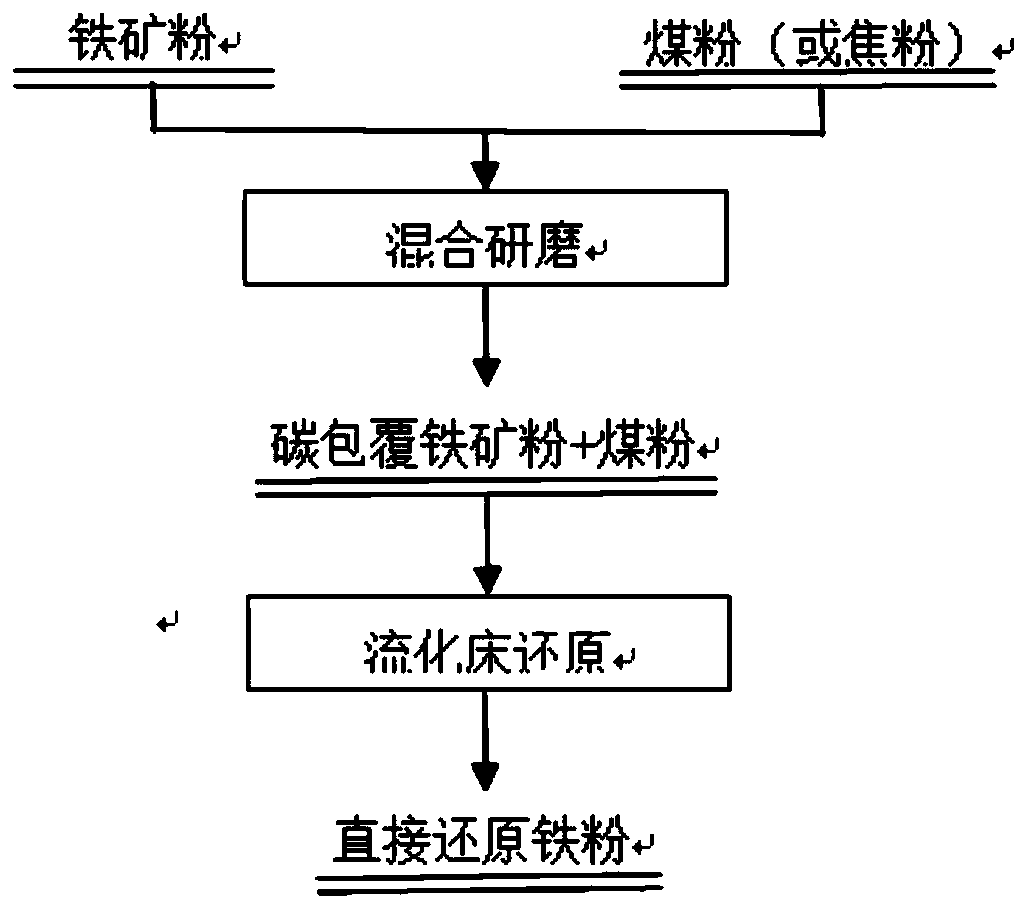

[0035] (1) Put the magnetite powder and anthracite powder less than 1.0mm into the ball mill and grind for 15 minutes.

[0036] (2) Add the ground product (including iron ore powder and coal powder coated with coal powder) directly into the fluidized bed, and at 870°C, feed CO=40%, H 2 =10%, N 2 =50% mixed gas, fluidized reduction for 60 minutes.

[0037] Results No cohesive loss occurred in the fluidized bed, no iron whisker was found in the sample after reduction, and the metallization rate was 90.3%.

Embodiment 3

[0039] (1) Put the hematite powder and anthracite powder less than 1.0mm into the ball mill and grind for 10 minutes.

[0040] (2) Then the iron ore powder is separated by gravity separation to obtain coal powder coated iron ore powder.

[0041] (3) Put the coal powder coated iron ore powder into the fluidized bed, at 820°C, feed CO=45%, H 2 =15%, N 2 =40% mixed gas, fluidized reduction for 50 minutes.

[0042] Results No cohesive loss occurred in the fluidized bed, no iron whisker was found in the sample after reduction, and the metallization rate was 89.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com