Conductive polybutylene foaming material and preparation method thereof

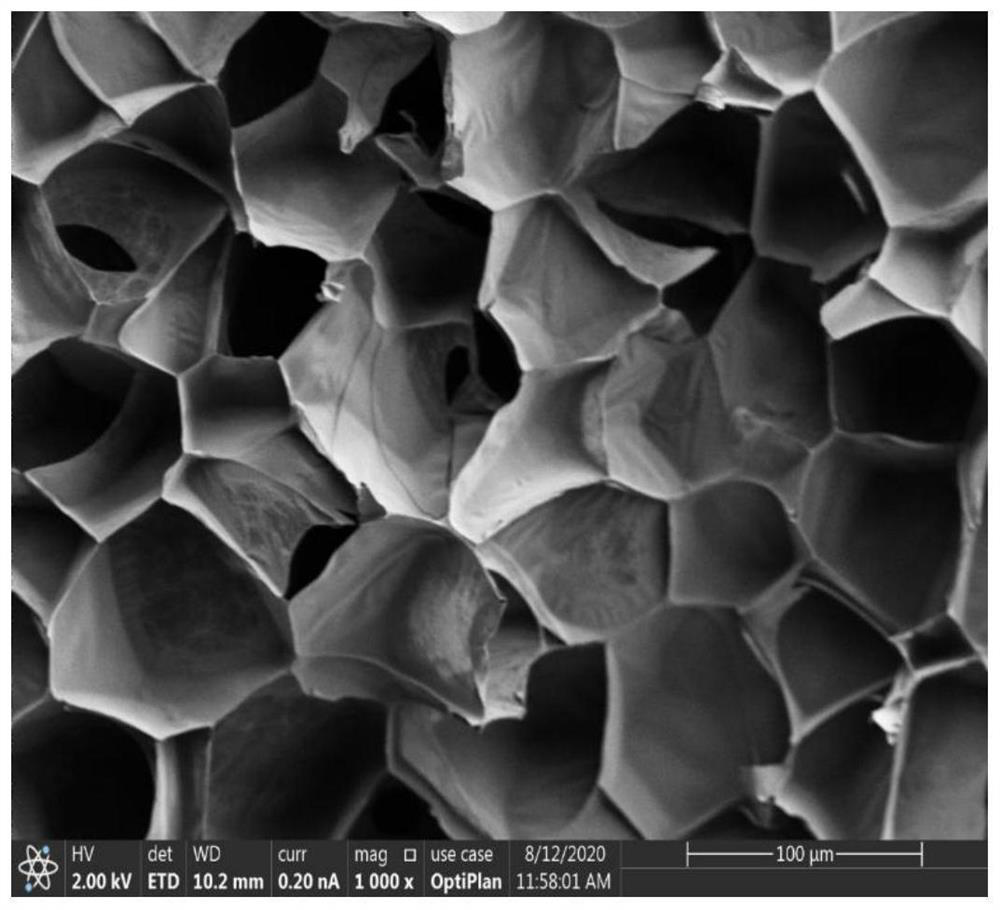

A technology of foaming material and polybutene, which is applied in the field of conductive polybutene foaming material and its preparation, can solve the problem of increasing the unit cost of polybutene foaming material, low yield of foaming products, and foaming material Surface shrinkage and other problems, to achieve the effect of small cell size, low shrinkage rate, and improved shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of a conductive polybutene foam material, comprising the following steps:

[0039] a) After mixing the raw materials, extruding and granulating, and then injection molding into a plate;

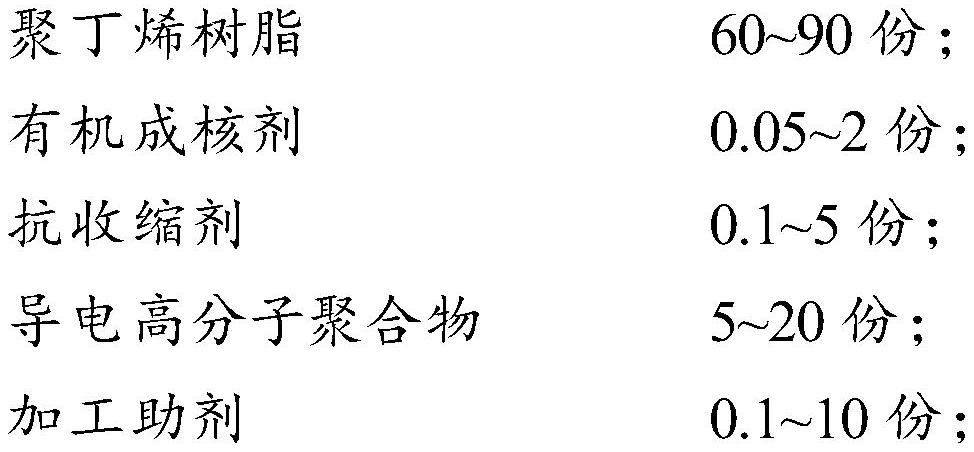

[0040] The raw material includes the following components by mass:

[0041]

[0042] in:

[0043] The organic nucleating agent is selected from one or more of cyclodextrin, calixarene, crown ether and cucurbit;

[0044] The injection pressure of the injection molding is 40~90bar, and the injection speed is 20~200cm 3 / s;

[0045] b) placing the plate in the mold cavity of the molding foaming equipment, after heating up, injecting supercritical fluid into the mold cavity and maintaining the pressure, and then releasing the pressure to obtain an initial foaming material;

[0046] c) cooling and shaping the initial foamed material to obtain a conductive polybutene foamed material.

[0047] In the preparation method provided by the presen...

Embodiment 1

[0084] S1, 80 parts of polybutene resin, 0.5 part of cyclodextrin, 1 part of glycerol monostearate, 10 parts of polyaniline, 0.1 part of antioxidant 1010, 0.5 part of silane coupling agent, 0.2 part of dodecyl Sodium benzenesulfonate and 0.1 part of oleic acid amide are uniformly mixed in a high-speed mixer, and then extruded and granulated by a twin-screw extruder. The temperature of the melting section of the extruder is 200 ° C, and then the extruded and granulated particles are injected. , the injection temperature is 200℃, the injection pressure is 55bar, and the injection speed is 85cm 3 / s. The thickness of the obtained injection-molded sheet is 4 mm, and the mass ratio of the crystal form I' in the polybutene crystals (crystal form I and crystal form I') is measured by DSC to be 12%, and the test results are shown in figure 1 , figure 1 It is the DSC bimodal structure diagram of the injection-molded sheet obtained in step S1 in Example 1.

[0085] S2. Place the 4mm ...

Embodiment 2

[0089] S1. Combine 85 parts of polybutene resin, 0.3 part of calixarene, 1.2 parts of molecularly distilled monoglyceride, 12 parts of polyacetylene, 0.1 part of antioxidant 168, 0.5 part of titanate coupling agent, 0.3 part of dodecyl Sodium sulfate and 0.15 parts of erucamide are uniformly mixed in a high-speed mixer, and then extruded and granulated by a twin-screw extruder. The temperature of the melting section of the extruder is 205°C, and then the extruded and granulated particles are injected by injection molding. The temperature is 190℃, the injection pressure is 65bar, and the injection speed is 75cm 3 / s. The thickness of the obtained injection-molded sheet is 5 mm, and the mass ratio of the crystal form I' in the polybutene crystals (crystal form I and crystal form I') is 15% as measured by DSC.

[0090] S2. Place the 5mm thick injection molding plate in the cavity of the molding foaming equipment, set the temperature to 115°C, after the temperature is stable, inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com