Manufacturing method for silicon carbide grinding barrel in grinding equipment

A manufacturing method and technology of silicon carbide, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of insufficient grinding barrel strength and insufficient wear resistance, and achieve stable physical properties, high specification and dimension accuracy, and excellent wear resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

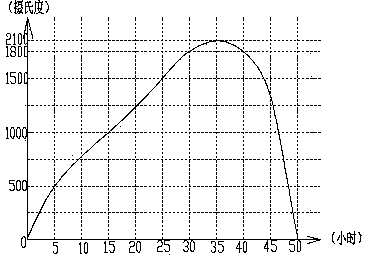

Image

Examples

Embodiment 1

[0038] Embodiment 1, a method for manufacturing a silicon carbide grinding bucket in a grinding device, comprising the following steps:

[0039] 1), ingredients

[0040] Add silicon carbide to the reaction catalyst and additives, add water while stirring, and stir evenly. The weight ratio of the various components is:

[0041] 65 parts of silicon carbide, 5 parts of reaction catalyst, 10 parts of additive; appropriate amount of water;

[0042] Silicon carbide, reaction catalysts and additives are compounded in granular powder, the size of the particles is between 2 microns and 150 microns, the main component of the reaction catalyst is carbon powder, and the main components of the additives are polyvinyl alcohol and dipropylene glycol Alcohol, according to the amount of water added, the material after batching can be made into slurry or powder.

[0043] 2. Blank forming

[0044] Use the mold to produce the blank of the silicon carbide grinding bucket of the corresponding s...

Embodiment 2

[0056]Embodiment 2, in step 1 of above-mentioned embodiment 1, the proportioning of described various component weights can also be: silicon carbide 75 parts, reaction catalyst 15 parts, additive 30 parts; 1 is the same.

Embodiment 3

[0057] Example 3, in the step 1 of the above-mentioned example 1, the weight ratio of the various components is: 70 parts of silicon carbide, 10 parts of reaction catalyst, 20 parts of additives; appropriate amount of water. Other processing steps are identical with embodiment 1.

[0058] In the above-mentioned Examples 1-3, silicon carbide reacts with reaction catalysts, additives and silicon alloys at high temperatures to produce composite silicon carbide. The main characteristics of this material are high temperature resistance, wear resistance, and corrosion resistance. The physical properties of the material are stable, and the sintered grinding barrel is mainly composed of this material. The invention adopts the above scheme, and the silicon carbide grinding barrel produced not only has excellent wear resistance performance, but also has high hardness, high specification and dimension precision, and long service life.

[0059] The performance comparison of silicon carbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com