Method for preparing magnetically regenerable immobilized bio-enzyme

A biological enzyme and magnetic technology, applied in the field of biological enzyme catalysis, can solve the problems of magnetic materials losing single-domain magnetic poles, loss of dispersibility, easy agglomeration and coagulation, etc., to facilitate recycling and regeneration, improve dispersion and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately weigh 13.104g FeSO with an electronic balance 4 ·7H 2 O in a small beaker, add 50ml of deionized water and stir to dissolve; 13.886gNa 2 S 2 o 3 ·5H 2 O in a small beaker, add 25ml of deionized water and stir to dissolve; add 4.480g of powdery NaOH to a small beaker, add 25ml of deionized water and stir to dissolve; after the dissolution is complete, mix NaOH aqueous solution and NaOH 2 S 2 o 3 The aqueous solution was transferred to a 250ml three-neck flask. Then FeSO 4 The aqueous solution was transferred to a constant pressure funnel, and the flow rate was controlled to allow the aqueous solution to drop into a three-necked flask. After the dropwise addition, turn on the electric stirrer to stir for 1 h, then transfer all the reactants in the three-neck flask into a hydrothermal kettle, and react at 160° C. for 16 hours. After the reaction, all the products were transferred to a watch glass, and the supernatant was sucked out after sedimentation w...

Embodiment 2

[0028] Surface modified Fe 3 o 4 The preparation of the granules is the same as in Example 1.

[0029] Weigh 1.0g of α-amylase and dissolve it in a 100ml beaker with buffer solution, stir with a glass rod for a period of time until the solid amylase dissolves, filter with filter paper to remove insoluble impurities, and transfer the obtained clear liquid to a 100ml volumetric flask, Set aside.

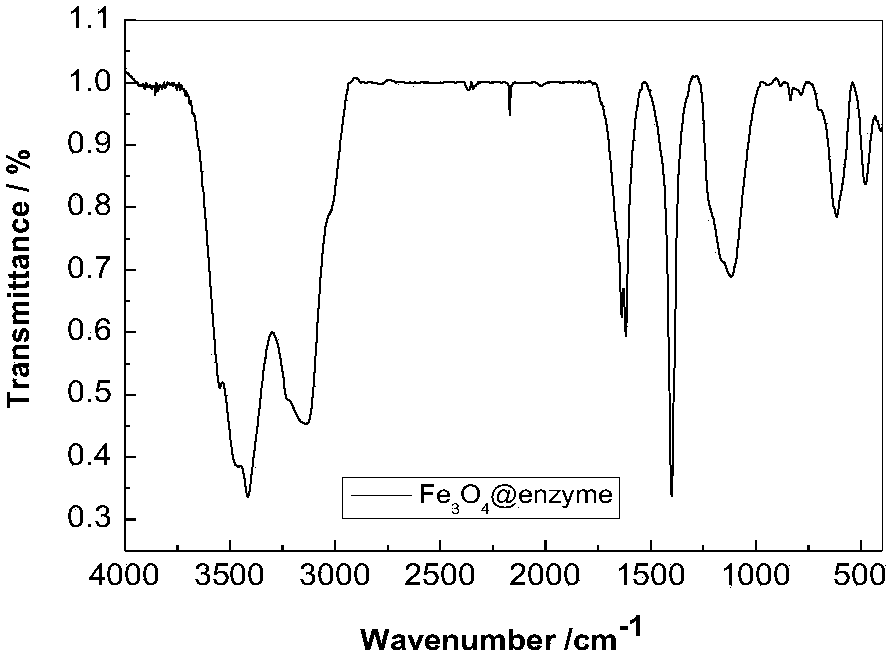

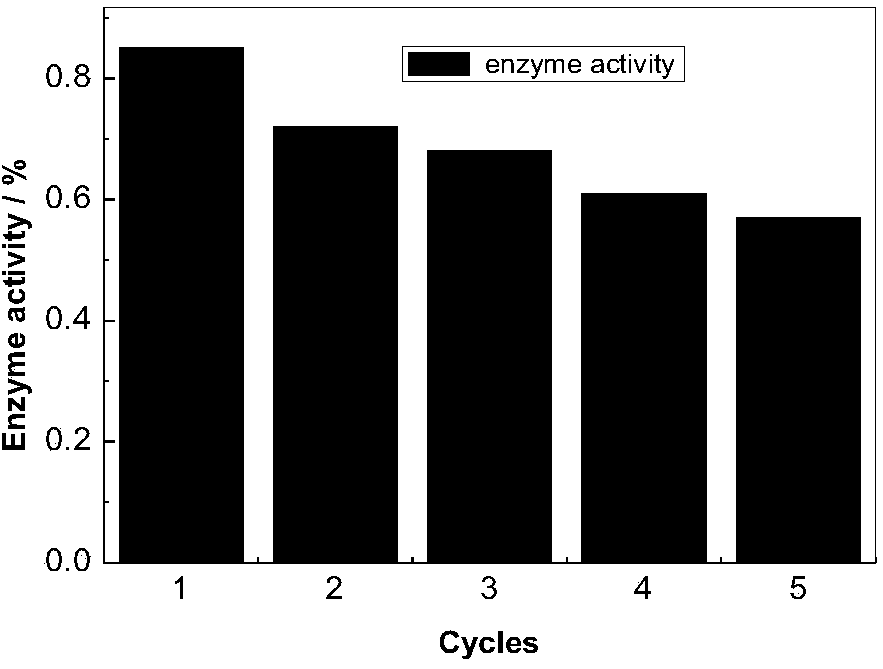

[0030] Weigh 0.1g of Fe after surface modification 3 o 4 Put the granules in a 250ml Erlenmeyer flask, add 100ml of buffer solution, add (accounting for the total volume) 1% crosslinking agent glutaraldehyde, crosslink and activate for 20min, measure the prepared α-amylase solution 10ml, added to the activated solution, reacted in a constant temperature oscillator for 2 hours, washed with deionized water for several times, and prepared a nano-magnetic material with α-amylase immobilized. After testing, the amylase activity after immobilization reached 87% of the free enzyme, and t...

Embodiment 3

[0032] Add 5.50g of cetyltetrabutylammonium bromide (CTAB), 16.50g of n-butanol and 68.00g of isooctyl alcohol into a 250ml three-necked flask and stir to form a homogeneous mixture, and add 10ml of 0.1M ferric chloride solution into the mixture , stir vigorously until orange and transparent, and pass through N 2 Protection, then slowly add 0.12g sodium borohydride powder, continue to stir and pass N 2 After the system turns black and no longer emits gas, continue to stir for half an hour. Stand still until all the black powder in the system sinks to the bottom of the bottle, suck out the upper liquid, add 50ml of methanol and chloroform mixed washing solution to wash, and use the same method to suck out the washing solution, then use 50ml of absolute ethanol, and use the same method Washing to obtain nanometer zero-valent ferromagnetic particles.

[0033] Weigh 54g of absolute ethanol, add 3g of deionized water, then add 2.38g of KH570, hydrolyze for about 10min, add 0.3g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com