A system and method for olefin polymerization

A technology for olefin polymerization and polymerization of monomers, applied in the field of olefin polymerization systems, can solve the problems of high energy consumption, increased investment, difficulty in separation and recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

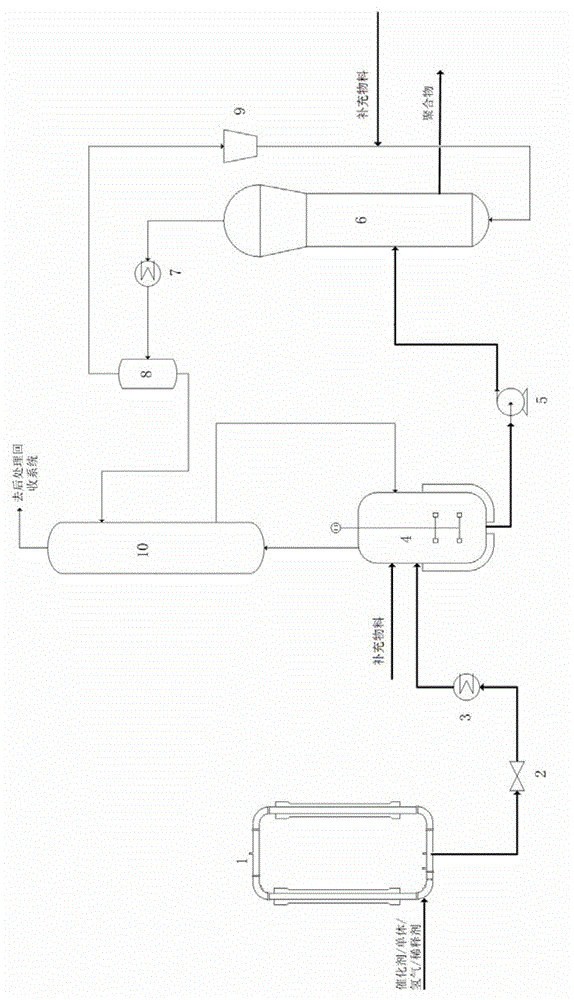

[0075] like figure 1 As shown, polyethylene with ultra-wide molecular weight distribution is produced in three series-connected reactors with an output of 300,000 tons / year, and the production rate distribution of the three reactors is 50:5:45. In the process, the Ziegler-Natta catalyst, diluent isobutane, ethylene, and hydrogen enter the first reactor 1—the loop reactor, with a reaction temperature of 95° C. and a pressure of 4.0 MPa. The feed rate of ethylene is 19962kg / hr, and the feed rate of hydrogen is adjusted so that the hydrogen / ethylene molar ratio in the slurry is 0.234. The output of polyethylene in the reactor effluent was 18750kg / hr, and the mass fraction of polymer in the slurry was 45%.

[0076] After the loop reactor effluent is decompressed, its temperature becomes 65°C, the pressure is 1.25MPa, and it contains 35.5% gas phase composition, and then enters the second reactor 4—the stirred tank reactor. The reaction temperature of the reactor is 75° C., and ...

Embodiment 2

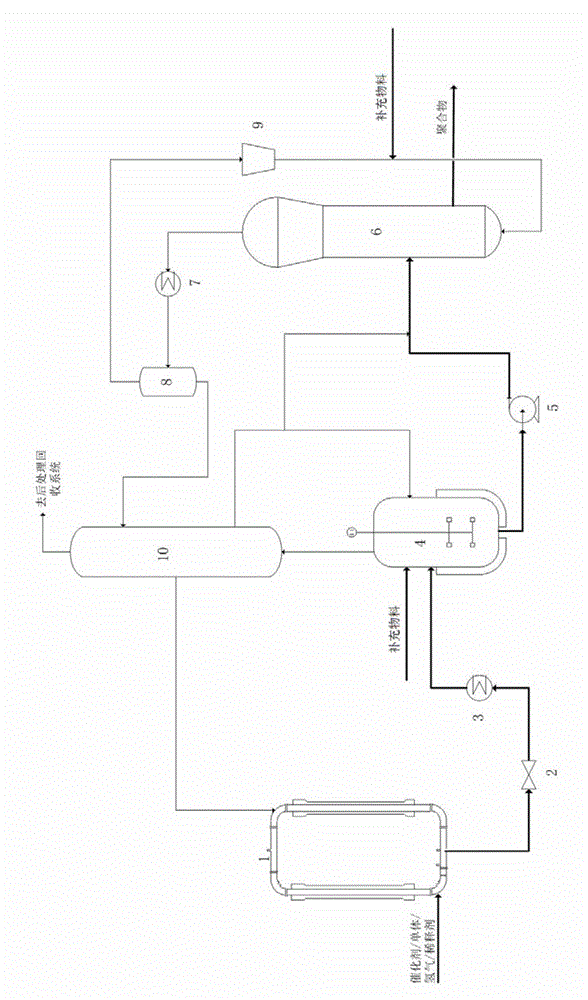

[0080] The operating conditions and material composition selection of the first reactor 1 and the third reactor 6 are the same as in Example 1, and by adjusting the separation capacity of the intermediate separation unit 10, the operating conditions of the second reactor 4—the stirred tank reactor are controlled , to achieve the purpose of producing the second type of ultra-wide molecular distribution polyethylene.

[0081] The reaction temperature of the second reactor is 75° C., and the pressure is 1.6 MPa. No comonomer is added to the reactor, the fresh feed only contains ethylene, and the flow rate is 1098kg / hr. The amount of diluent isobutane entering the reactor is controlled by the separation unit 10 to ensure normal operation of the slurry reaction. The hydrogen / ethylene molar ratio in the reactor was 0.106. The flow rate of polyethylene in the reactor effluent is 20625kg / hr, and the mass fraction of polymer in the slurry is 43%.

[0082] The reactor effluent is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com