Production process of belt treble diaphragm

A production process and high-pitch diaphragm technology, applied in electrical components, sensors, etc., can solve the problems of large space occupation, unreported production process, and large limitations of acoustic design, achieving small noise, strong operability, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

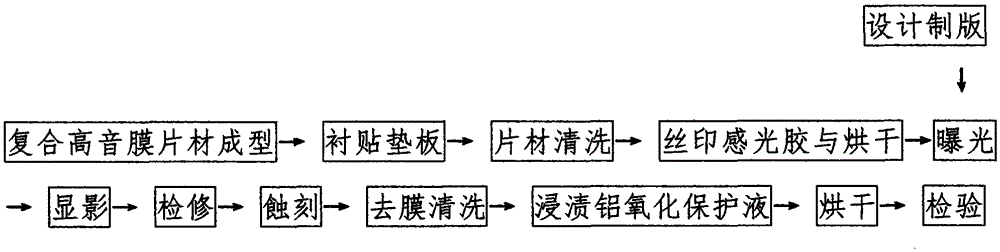

[0030] The following takes the compound treble diaphragm of the model DK141×43-4 as an example, and describes its production process in detail in conjunction with Figure 1.

[0031] 1. Design and plate making:

[0032] Using computer CAD system to draw, design the overall size of the composite treble diaphragm and its electronic circuit; the designed electronic circuit graphics are processed by a 16000DPI high-resolution photoplotter.

[0033] The electronic circuit calculates the height, width and length of the electronic circuit based on the resistance value required by the composite tweeter diaphragm process and the area of the composite tweeter diaphragm according to the principle of square resistance, and draws the circuit diagram. In order to meet the requirements of the resistance value after the product is finished, in addition to referring to the theoretical basis, the technical parameters summarized by the experiment are needed. The design resistance value of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com