A kind of water-based dumb silver transfer coating and preparation method thereof

A technology for transferring paint and dumb silver, applied in the field of paint, can solve problems such as hue deviation, and achieve the effect of high porosity, good applicability, uniform and single hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

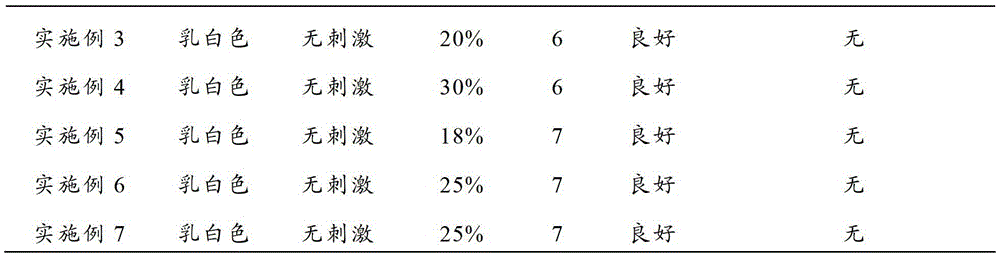

Examples

preparation example Construction

[0041] The preparation method of the water-based polyurethane of the present invention adopts the internal emulsification method, that is, the molecular chain contains hydrophilic groups, and no external emulsifier is needed. In the preparation process, firstly, isophorone diisocyanate and polyester diol are used to synthesize - The prepolymer of the NCO end group is then added with an alcohol chain extender and a hydrophilic chain extender for chain extension reaction, and finally dispersed in water dissolved in triethylamine to obtain high molecular weight waterborne polyurethane by chain extension. Since a hydrophilic group is introduced into the polyurethane polymer, it can be dissolved in water, so it can be used as a water dispersion of water-based dumb silver transfer coating, which can be uniformly dispersed in deionized water. Above-mentioned polyester diol is preferably polycaprolactone diol, and described alcohol diffusion agent is preferably 1,4-butanediol, and desc...

Embodiment 1

[0052] Distill 220g of polycaprolactone diol at 130°C for 2h and then cool down to room temperature, add 100g of isophorone diisocyanate and 3g of stannous octoate and react at 80-140°C for 2-3h, After cooling down, add 10g of dimethylolpropionic acid and 12g of 1,4-butanediol, continue the reaction for 4 to 8 hours, then cool down and add 12g of triethylamine and 53g of N-methylpyrrolidone as salt forming agents, and finally add 590g of deionized water to carry out Chain extension to obtain water-based polyurethane.

Embodiment 2

[0054] Distill 160g of polycaprolactone diol at 130°C for 2h and then cool down to room temperature, add 120g of isophorone diisocyanate and 4g of stannous octoate and react at 80-140°C for 2-3h, After cooling down, add 18g of dimethylolpropionic acid and 14g of 1,4-butanediol, continue the reaction for 4-8 hours, then cool down and add salt-forming agents 18g of triethylamine and 53g of N-methylpyrrolidone, and finally add 613g of deionized water to carry out Chain extension to obtain water-based polyurethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com