Production method of bromhexine hydrochloride

A technology of bromhexine hydrochloride and glacial acetic acid, which is applied in the field of medicine and chemical industry, can solve problems such as low recovery rate, low recovery rate, and difficulty in solvent recovery and treatment, and achieve the effects of reducing costs, reducing moisture content, and reducing waste of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

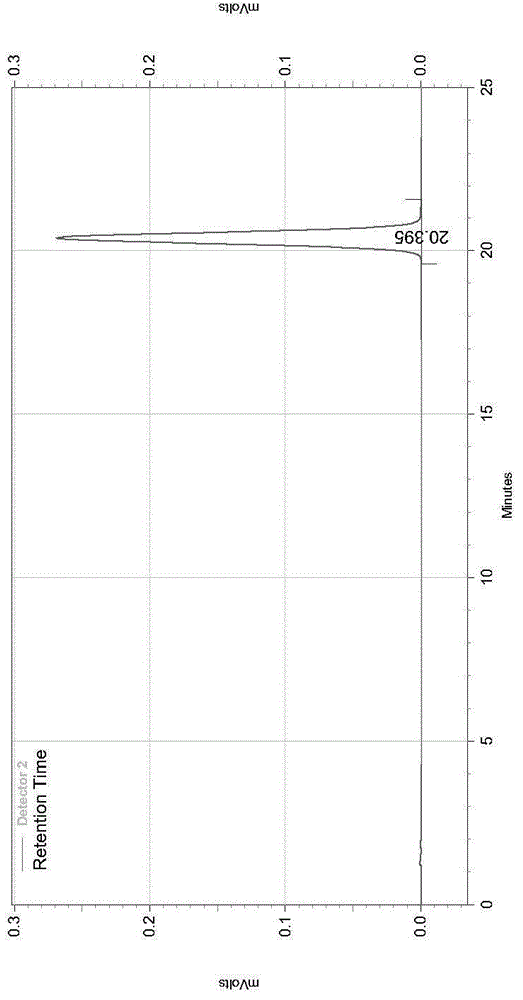

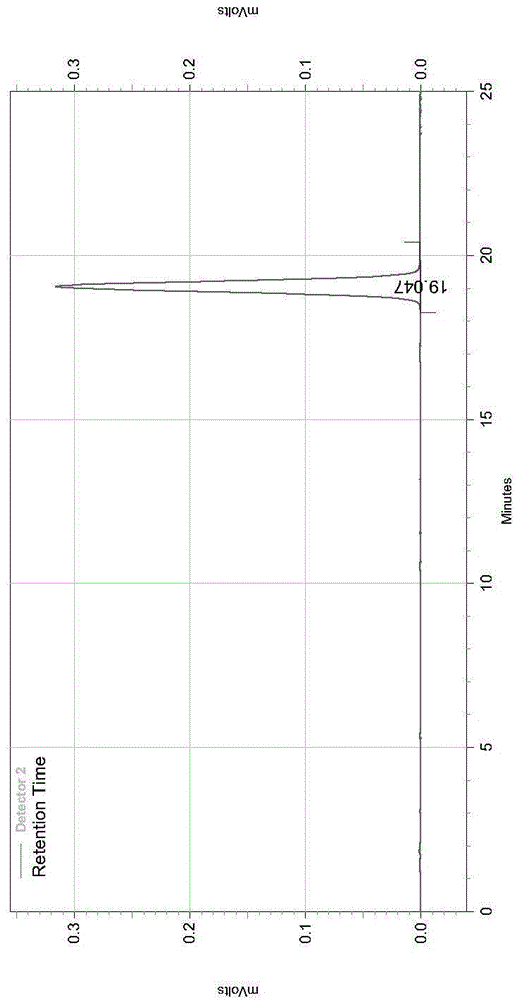

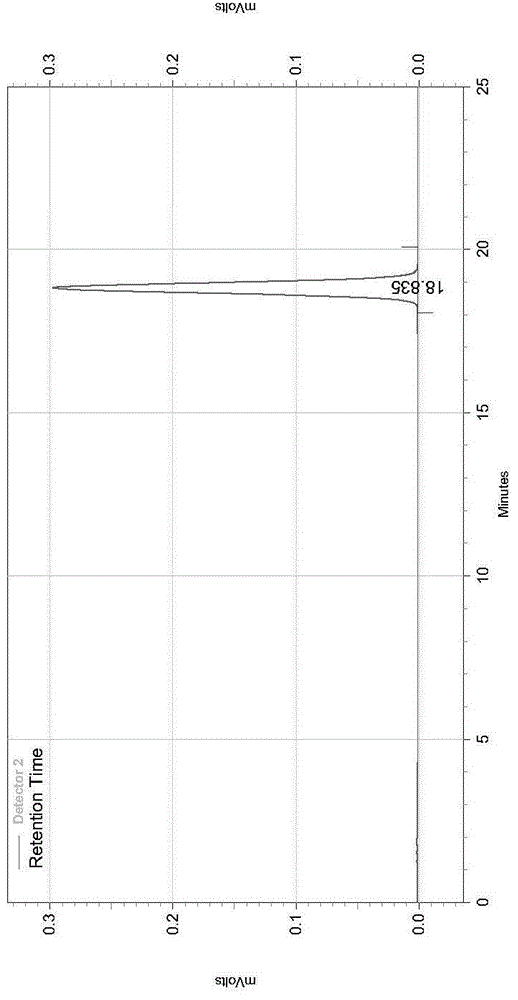

Image

Examples

Embodiment 1

[0040] Preparation of crude N-methyl-N-cyclohexyl-2-amino-3,5-dibromobenzylamine hydrochloride.

[0041] Feeding ratio:

[0042] raw material name Quantity(Kg) raw material name Quantity(Kg) reduction 94 toluene 3±1 Glacial acetic acid 49±1 30% hydrochloric acid 48±5 N-Methylcyclohexylamine 114±1 water 48±5 ethanol 125±1

[0043] In a 300L electric heating reaction pot, put N-methylcyclohexylamine, add the reducing substance under stirring, stir to dissolve, then slowly add glacial acetic acid dropwise, and finally add toluene; open the pipeline valve of the distillation water separation device, cooling water and refrigeration refrigerant Corresponding to the valve, heat the jacket to raise the temperature to reflux and divide the water; then slowly increase the temperature until the end of the reaction (the end of the water division), and control the temperature in the pot at the end of the reaction to about 170-180°C...

Embodiment 2

[0046] Preparation of crude N-methyl-N-cyclohexyl-2-amino-3,5-dibromobenzylamine hydrochloride.

[0047] Feeding ratio:

[0048] raw material name Quantity(Kg) raw material name Quantity(Kg) reduction 188 toluene 5±1 Glacial acetic acid 98±1 30% hydrochloric acid 96±5 N-Methylcyclohexylamine 228±1 water 96±5 Methanol 250±1

[0049] In a 500L electric heating reaction pot, put N-methylcyclohexylamine, add the reducing substance under stirring, stir to dissolve, then slowly add glacial acetic acid dropwise, and finally add toluene; open the pipeline valve of the distillation water separation device and the cooling water and refrigerant Corresponding to the valve, heat the jacket to heat up to reflux for water separation; then slowly increase the temperature until the end of the reaction (end of water separation), and finally control the temperature in the pot to be about 170-180°C.

[0050] Preheat the 1000L salt-formin...

Embodiment 3

[0052] Condensation-salt-forming section: prepare crude N-methyl-N-cyclohexyl-2-amino-3,5-dibromobenzylamine hydrochloride.

[0053] Feeding ratio:

[0054] raw material name Quantity(Kg) raw material name Quantity(Kg) reduction 188 toluene 5±1 Glacial acetic acid 98±1 30% hydrochloric acid 96±5 N-Methylcyclohexylamine 228±1 water 96±5 acetone 300±1

[0055] In a 500L electric heating reaction pot, put N-methylcyclohexylamine, add the reducing substance under stirring, stir to dissolve, then slowly add glacial acetic acid dropwise, and finally add toluene; open the pipeline valve of the distillation water separation device and the cooling water and refrigerant Corresponding to the valve, heat the jacket to heat up to reflux for water separation; then slowly increase the temperature until the end of the reaction (end of water separation), and finally control the temperature in the pot to be about 170-180°C.

[0056] Preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com