Oxygen reduction electrocatalyst and preparation method thereof

An electrocatalyst and peroxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of expensive fuel cells and reduce H2O2 Yield, low cost, effect of increasing active site density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

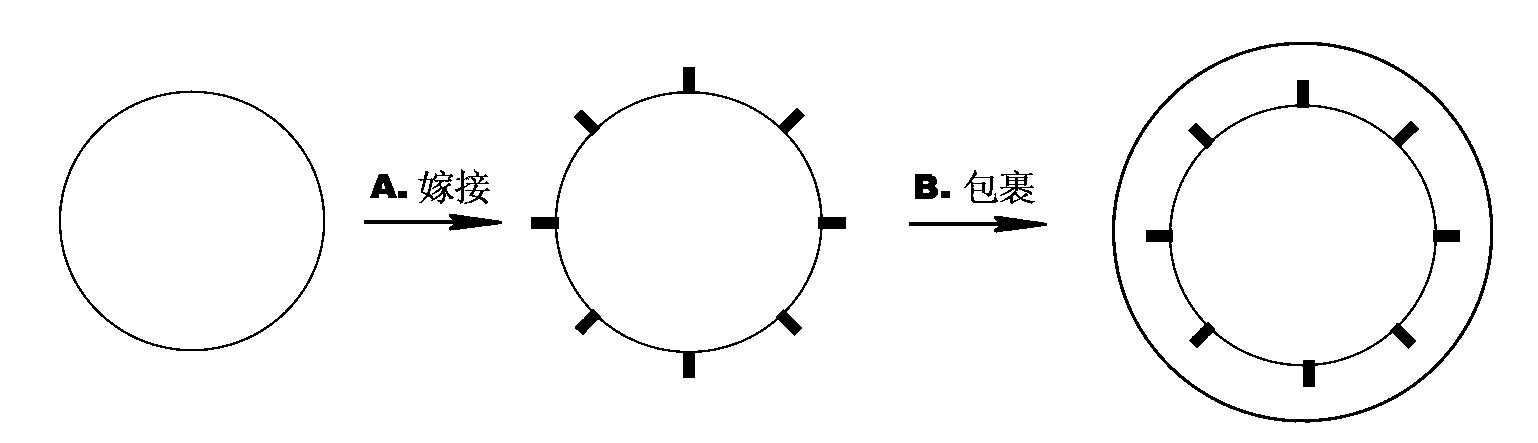

Method used

Image

Examples

Embodiment 1

[0063] (1) Carbon black screening: Dissolve 2g of Ketjenblack EC600JD carbon black (KJ600 for short) in 300mL of deionized water, and sonicate for 1h. Pass through a 100-200 mesh sieve, and sonicate again for 1 hour. Mechanical stirring further makes the carbon black evenly dispersed in water. Store at a low temperature of 0-10°C for later use. Thermogravimetric results for carbon black, see Figure 4 , curve 1.

[0064] (2) Grafting of carbon black: weigh 0.1-2.4g p-aminobenzenesulfonic acid (p-NH 2 -Ph-SO 3 H) Powdery solid, add 50-100mL ultra-pure water, under the low temperature condition of 0-10 ℃, slowly add 1M NaOH solution cooled by ice water in advance, dissolve p-aminobenzenesulfonic acid under constant stirring, and obtain p-aminobenzenesulfonic acid Sodium (p-NH 2 -Ph-SO 3 Na). Slowly add 1M HCl solution cooled by ice water dropwise while stirring to obtain milky white p-aminobenzenesulfonic acid (p-NH 2 -Ph-SO 3 H) Suspension, and make the solution acidi...

Embodiment 2

[0077] See Table 1 for specific conditions and results.

[0078] Table 1

[0079]

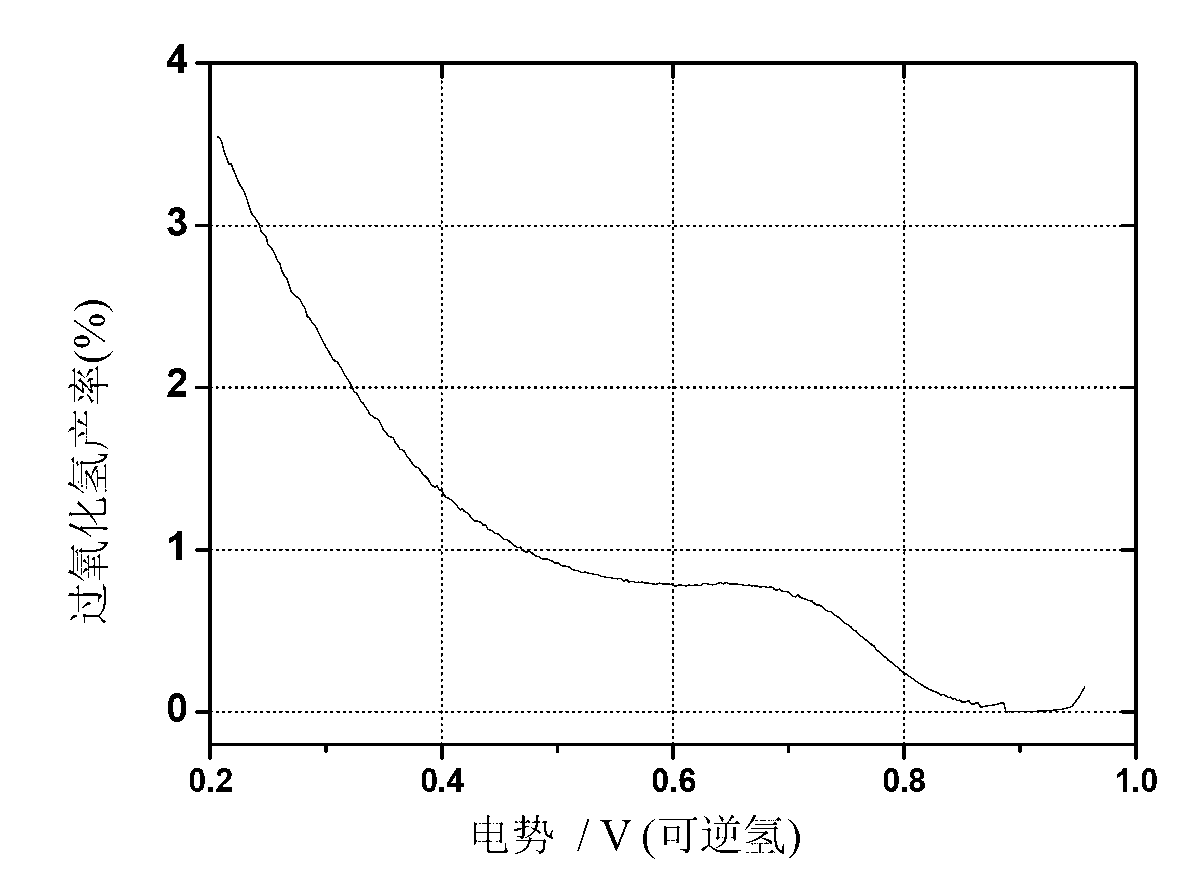

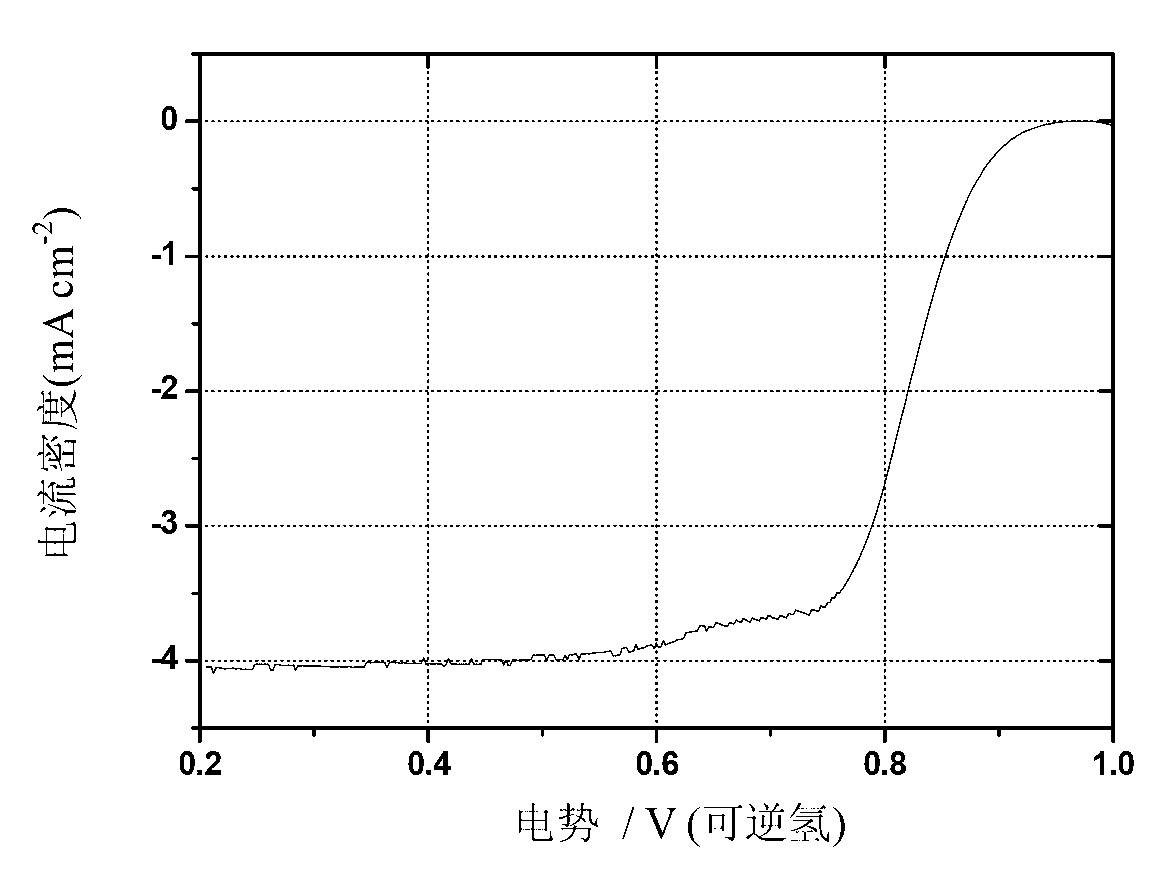

[0080] The change of the carbon black carrier has a significant effect on the activity and the yield of hydrogen peroxide.

Embodiment 3

[0082] See Table 2 for specific conditions and results.

[0083] Table 2

[0084]

[0085] The amount of aminobenzenesulfonic acid derivatives will affect the effect of wrapping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com