Multifunctional inorganic thermal insulation material composition, product comprising same and preparation method of product

An inorganic thermal insulation material and an inorganic thermal insulation technology, applied in the field of multifunctional inorganic thermal insulation material compositions, can solve the problems of damage, complex thermal insulation, waterproof and fireproof construction, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

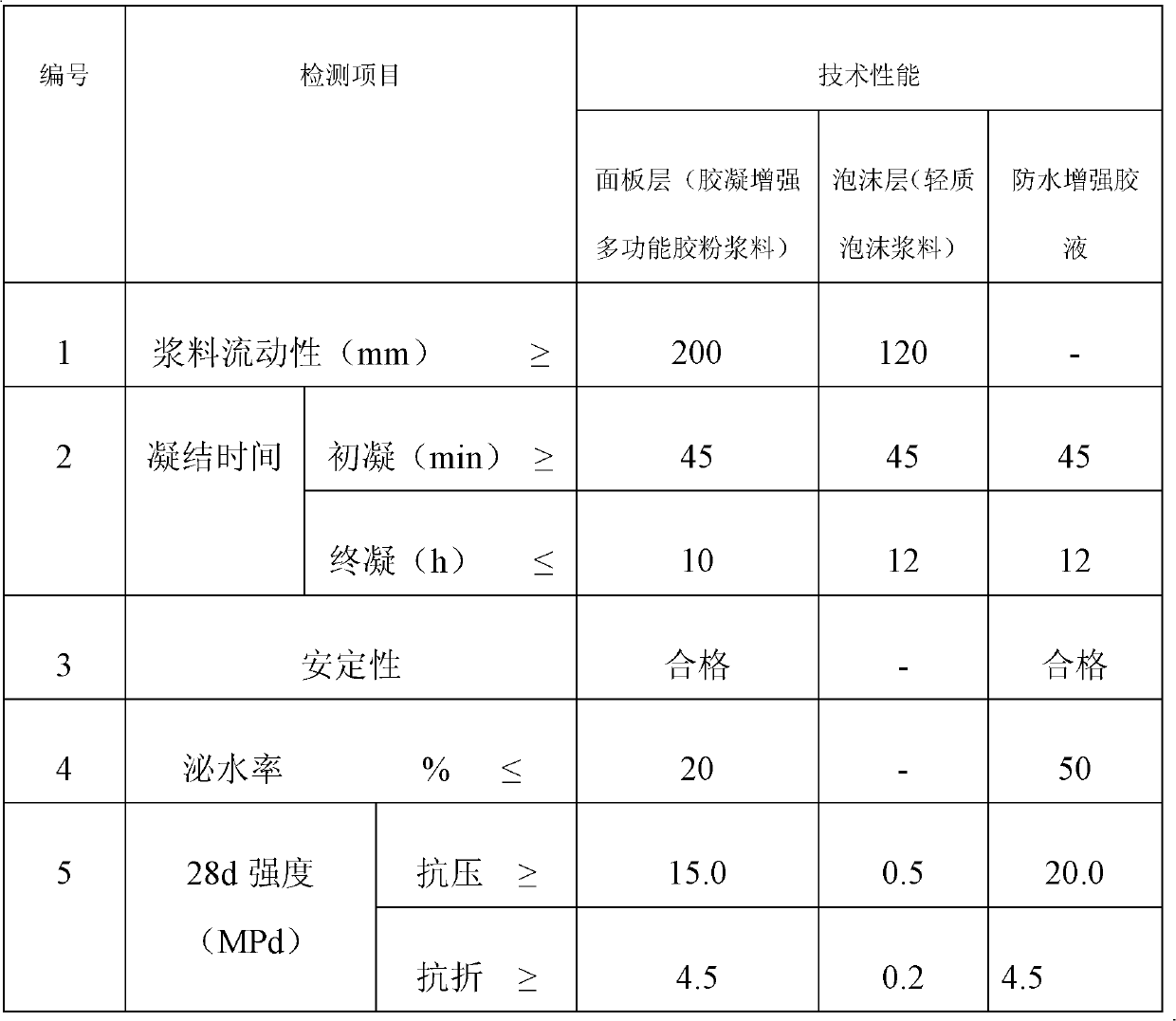

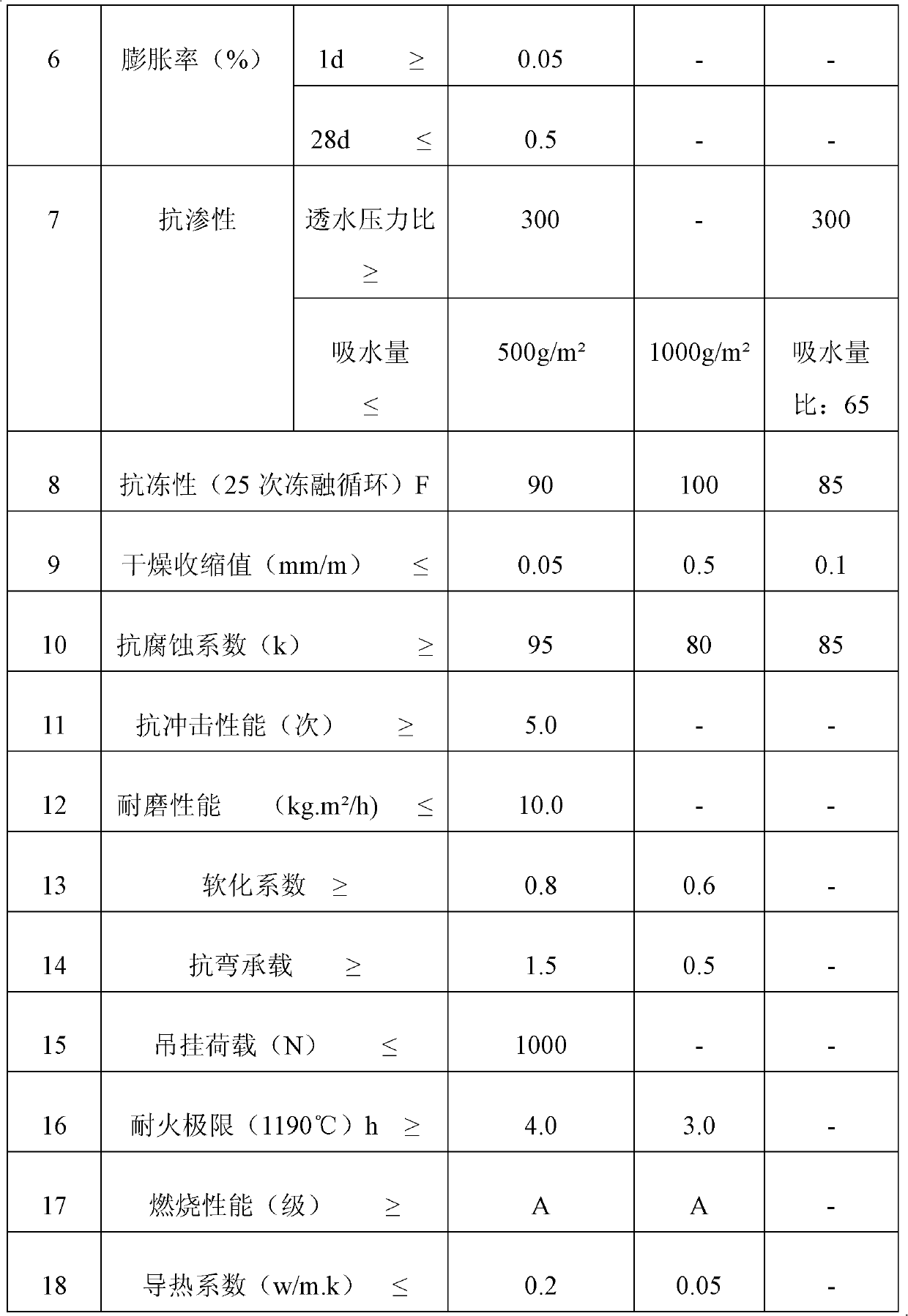

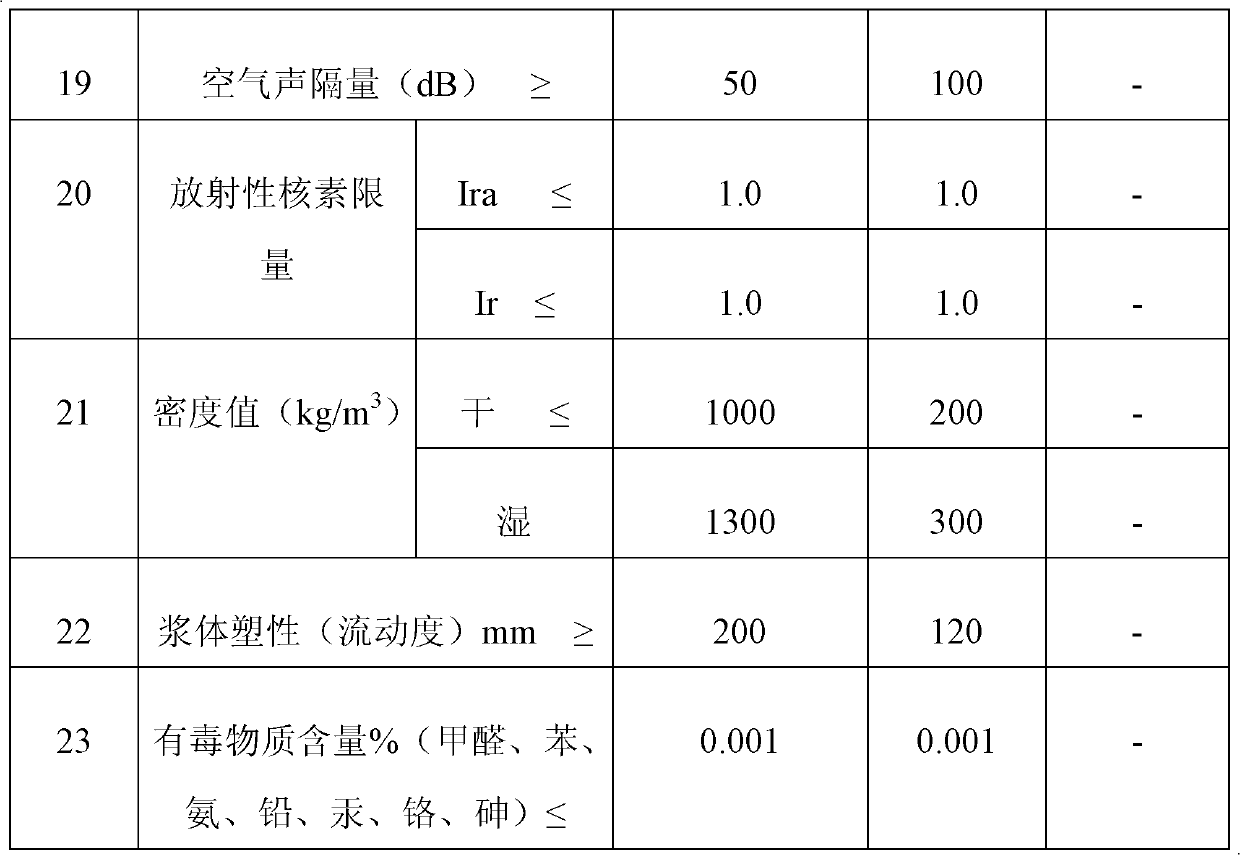

Image

Examples

Embodiment 1

[0110] Example 1 Preparation of multifunctional inorganic thermal insulation wallboard product.

[0111] (1) The proportioning ratio of gelling enhanced multifunctional rubber powder slurry composition is: gelling enhanced multifunctional rubber powder 65.0% by weight (wherein, 30.0% by weight of phosphogypsum material, 15% by weight of Portland cement, 10% by weight of silica-alumina powder % by weight, 3.0% by weight of steel slag powder, 5.0% by weight of waste brick powder, 2.0% by weight of latex powder), 3.0% by weight of coagulation enhancing agent (wherein, 1.0% by weight of citric acid, 0.5% by weight of sodium pyrophosphate, 0.5% by weight of zinc sulfate %, triethanolamine 0.2% by weight, hydroxypropyl methylcellulose 0.3% by weight, aluminum sulfate 0.5% by weight), dispersant 1.5% by weight (among them, polycarboxylate superplasticizer 0.8% by weight, calcium sulfonate 0.3% by weight % by weight, 0.4% by weight of sulfamate superplasticizer), 0.2% by weight of cel...

Embodiment 2

[0118] Embodiment 2 Preparation of Multifunctional Inorganic Thermal Insulation Roofing Products

[0119] (1) The ratio of the gelling enhanced multifunctional slurry composition is: 65.0% by weight of gelling enhanced multifunctional powder (35.0% by weight of phosphogypsum powder, 15.0% by weight of ordinary Portland cement, 5.0% by weight of phosphorus slag powder, Latex powder 5.0% by weight, slag powder 5.0% by weight), coagulation regulator 3.0% by weight (wherein sodium tripolyphosphate 0.4% by weight, borax 0.6% by weight, aluminum trichloride 1.0% by weight, sodium sulfate 1.0% by weight), 1.5% by weight of dispersant (including 0.2% by weight of calcium sugar, 0.8% by weight of naphthalene-based water reducer, and 0.5% by weight of early-strength water reducer), 0.2% by weight of fiber, 0.3% by weight of hydroxypropyl cellulose, and up to 100% by weight % of the balance of water (tap water).

[0120] Take the production of 1000kg gelled reinforced multifunctional ru...

Embodiment 3

[0126] Embodiment 3 Preparation of Multifunctional Inorganic Thermal Insulation Block (block) Product

[0127] (1) The proportioning ratio of the lightweight foam slurry composition is: 50% by weight of gelling enhanced multifunctional rubber powder (wherein, 10% by weight of dihydrate gypsum, 12.0% by weight of phosphogypsum, 10% by weight of ordinary Portland cement, sulfur 5.0% by weight of aluminate cement, 5.0% by weight of steel slag powder, 5.0% by weight of waste masonry powder, 3.0% by weight of latex powder), 1.5% by weight of setting modifier (wherein sodium gluconate is 0.5% by weight, sodium sulfate is 1.0% by weight) , dispersant 2.5% by weight (wherein, polycarboxylate superplasticizer 1.5% by weight, wood sodium 0.3% by weight, early strength superplasticizer 0.7% by weight), air-entraining foaming agent 3.0% by weight (wherein, hydrogen peroxide 2.5% by weight , sodium lauryl sulfate 0.3% by weight, Neal 0.2% by weight), thickener 0.6% by weight (wherein, hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com