A polysulfone hollow fiber dialysis membrane and its manufacturing method

A hollow fiber and manufacturing method technology, applied in the field of hemodialysis, can solve the problems such as failure to solve the membrane anticoagulation and anti-protein adsorption capacity, high cost, time-consuming and the like, and achieve strong anticoagulation and anti-protein adsorption capacity, Avoid activation, high clearance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

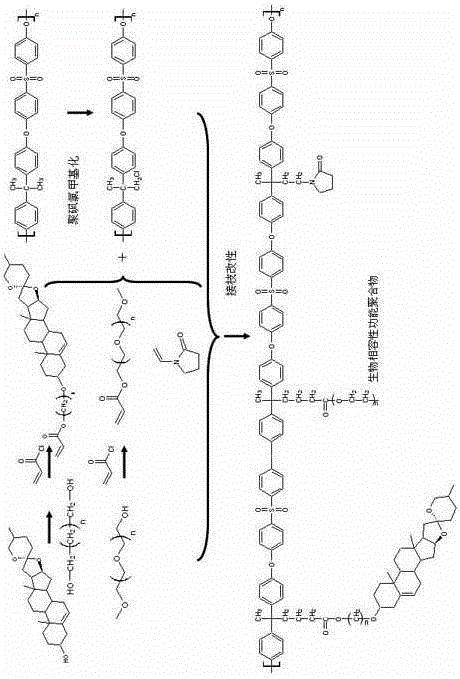

Method used

Image

Examples

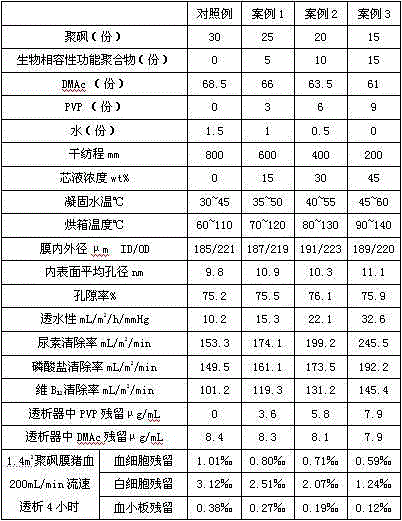

Embodiment 1

[0028] A polysulfone hollow fiber dialysis membrane, which is processed from the following raw materials in proportion by mass: 25 parts of polysulfone, 25 parts of biocompatible functional polymer, 10 parts of polyvinylpyrrolidone, and dimethylacetamide as the solvent (DMAc) 100 parts. Among them, the biocompatible functional polymer is prepared from diosgenin, polyethylene glycol, N-vinylpyrrolidone, and polysulfone through the following polymer chemical synthesis and graft modification methods: combining diosgenin with dihydroxy Linking fragments of terminal functional groups (such as methylene repeating units, vinyl chloride structural units, etc.) In 10 parts of dichloromethane, dissolve an excess of 5% to 10% acryloyl chloride in chloroform, and slowly add it dropwise to the diosgenin solution for condensation esterification, triethylamine is an organic base catalyst, at -20°C React at 0°C for 5 to 8 hours. , and then separated and purified by chromatographic column to...

Embodiment 2

[0032] A polysulfone hollow fiber dialysis membrane, which is processed from the following raw materials in proportion by mass: 5 parts of polysulfone, 50 parts of biocompatible functional polymer, 1 part of polyethylene glycol, and solvent dimethylacetamide (DMAc) 200 parts; wherein the biocompatible functional polymer is prepared from heparin, polyvinyl alcohol, polymethyl methacrylate and polysulfone through a polymer synthesis method and a graft modification method.

[0033] Its manufacturing method is as follows: select raw materials according to the ratio of parts; put the selected raw materials into a stirring tank, and stir at 80°C for 24 hours to form a homogeneous solution; introduce the homogeneous solution into the spinning tank, and vacuumize and defoam. It is extruded from a spinneret at 20°C, passed through a 1000mm dry spinning process, coagulated by a coagulation device, dried by a drying device, and finally collected by a winding device to obtain a finished pr...

Embodiment 3

[0035] A polysulfone hollow fiber dialysis membrane, which is processed from the following raw materials in proportion by mass: 40 parts of polysulfone, 1 part of biocompatible functional polymer, 20 parts of polyethylene glycol, and solvent dimethylacetamide (DMAc) 100 parts; wherein the biocompatible functional polymer is prepared from diosgenin, polymethyl methacrylate, polysaccharide and polysulfone through a polymer synthesis method and a graft modification method.

[0036] Its manufacturing method is as follows: select raw materials according to the ratio of parts; put the selected raw materials into a stirring tank, and stir at 120°C for 8 hours to form a homogeneous solution; introduce the homogeneous solution into the spinning tank, and vacuumize and defoam. It is extruded from a spinneret at 90°C, passed through a 100mm dry spinning process, coagulated by a coagulation device, dried by a drying device, and finally collected by a winding device to obtain a finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com