Graphene high-frequency nanomechanical resonator based on flexible substrate and preparing technology of graphene high-frequency nanomechanical resonator

A flexible substrate and preparation technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of improving and limiting the electromechanical resonance frequency of graphene beam nanometers, and achieve the effect of increasing the resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

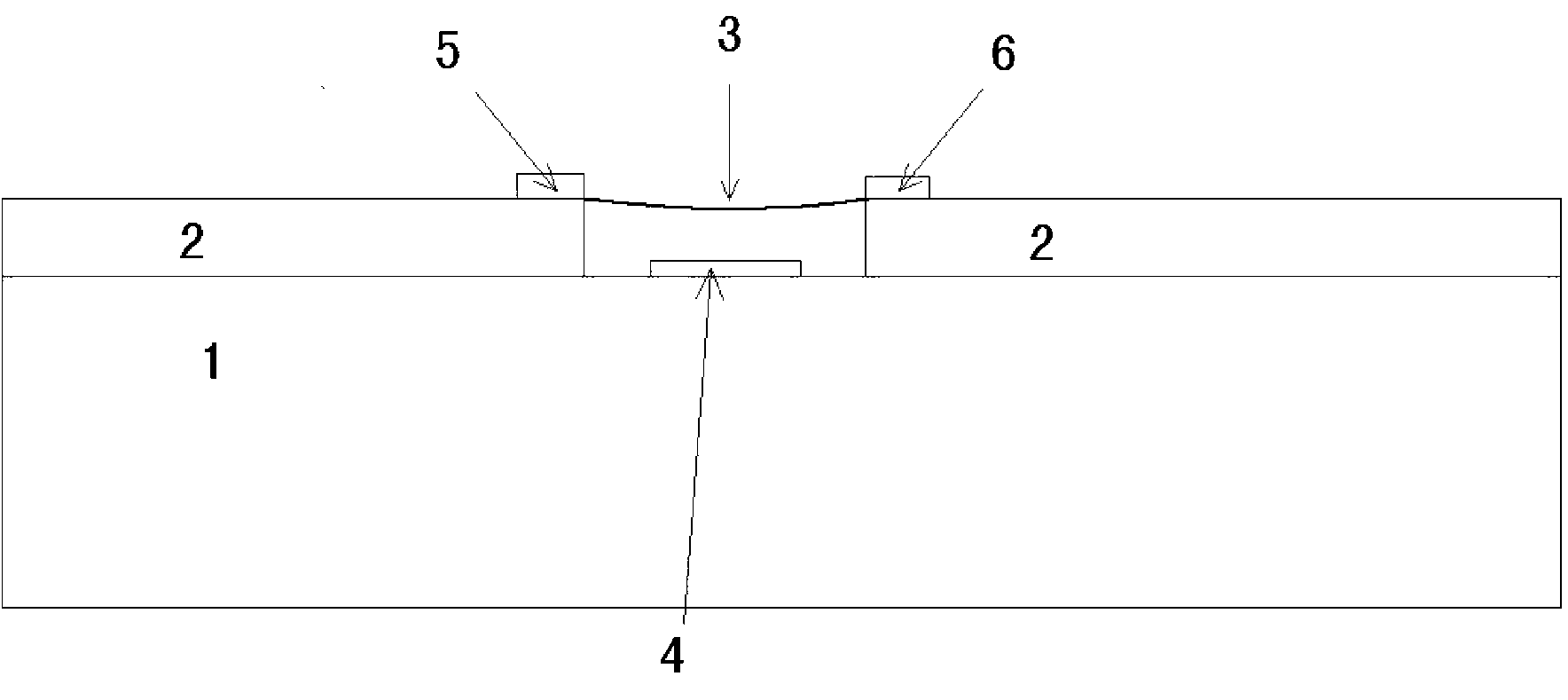

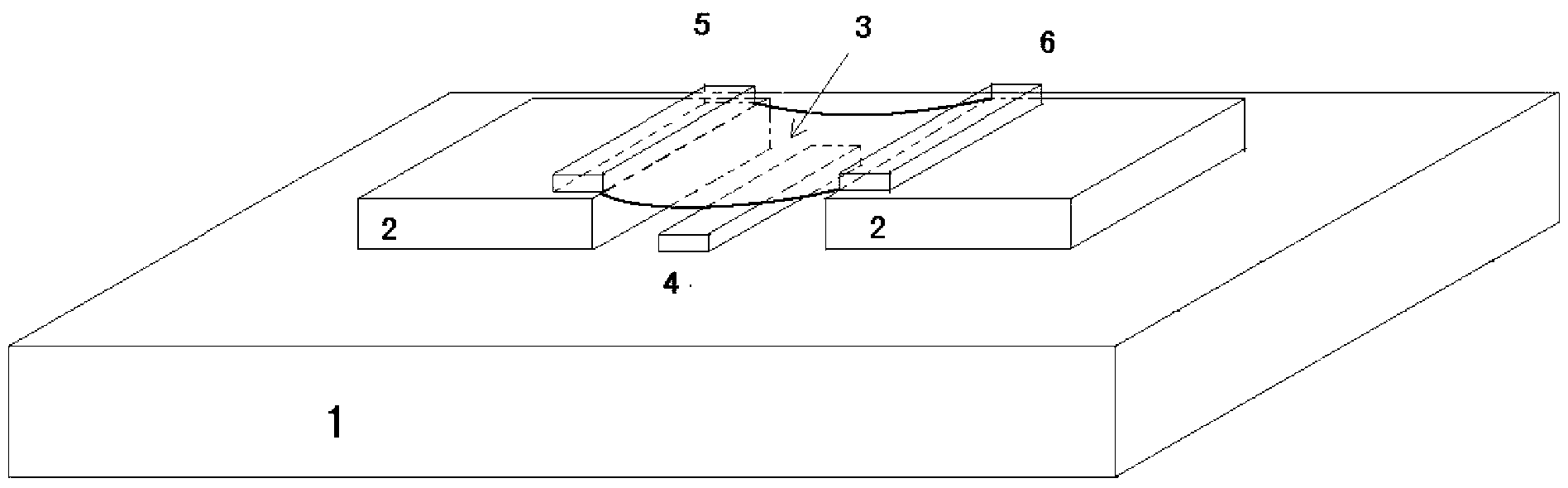

[0034] The preparation technology of the high-frequency graphene nano-electromechanical resonator based on flexible substrate of the present invention, its operating steps are as follows:

[0035] Step 1: Spin-coat photoresist (PMMA) on polyethylene naphthalate (PEN) flexible substrate 1, and use electron beam etching to make the shape of gate metal electrode 4, with a gate length of 300nm and a gate width of 500nm ;

[0036] Step 2: Evaporate a layer of titanium metal with a thickness of 1 nm and a layer of gold-platinum alloy with a thickness of 30 nm on the surface of the flexible substrate 1 in step 1 by evaporation; then remove the excess photoresist and the metal attached to it, leaving only A patterned gate metal electrode 4 on the lower flexible substrate 1;

[0037] Step 3: Deposit a layer of silicon dioxide (SiO 2 ) dielectric layer 2;

[0038] Step 4: Spin-coat photoresist (PMMA) on the prepared graphene wafer, and then put the graphene wafer into iron nitrate (F...

Embodiment 2

[0046] In this example, the flexible material polyethylene naphthalate (PEN) used in Example 1 is replaced by polyethylene terephthalate (PET), and plasma-enhanced chemical vapor deposition is used on the flexible substrate 1 (PECVD) deposited a layer of silicon dioxide (SiO 2 ) Dielectric layer 2, the width of the graphene channel is 2000nm; other process steps and process conditions are the same as in Example 1, and a graphene-based high-frequency and high-Q nanoelectromechanical resonator based on a flexible substrate can also be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com