Multi-layer composite ceramic oxygen permeation film as well as preparation and application thereof

An oxygen permeable membrane and multilayer composite technology, which is applied in the field of multilayer composite ceramic oxygen permeable membrane and its preparation and application, can solve the problems of thermal expansion matching oxygen flux decline, development limitation, high chemical stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

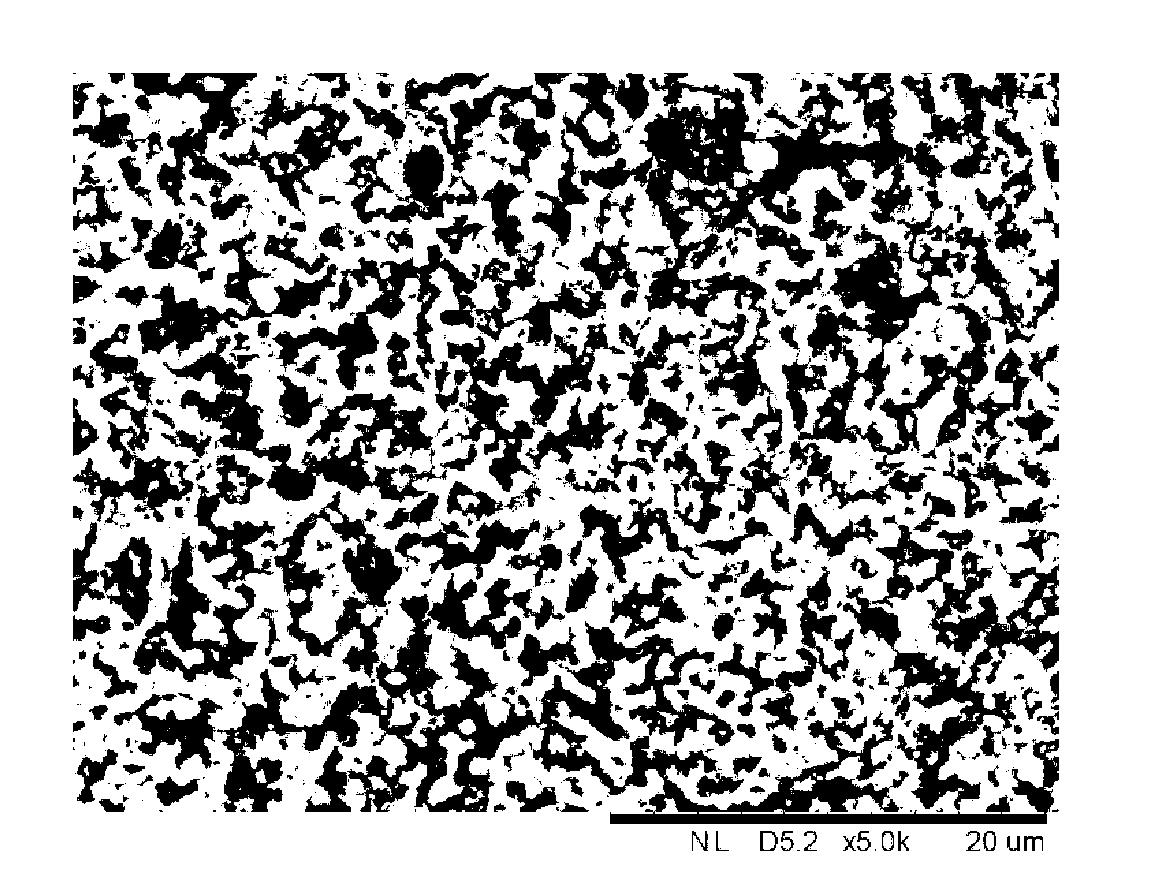

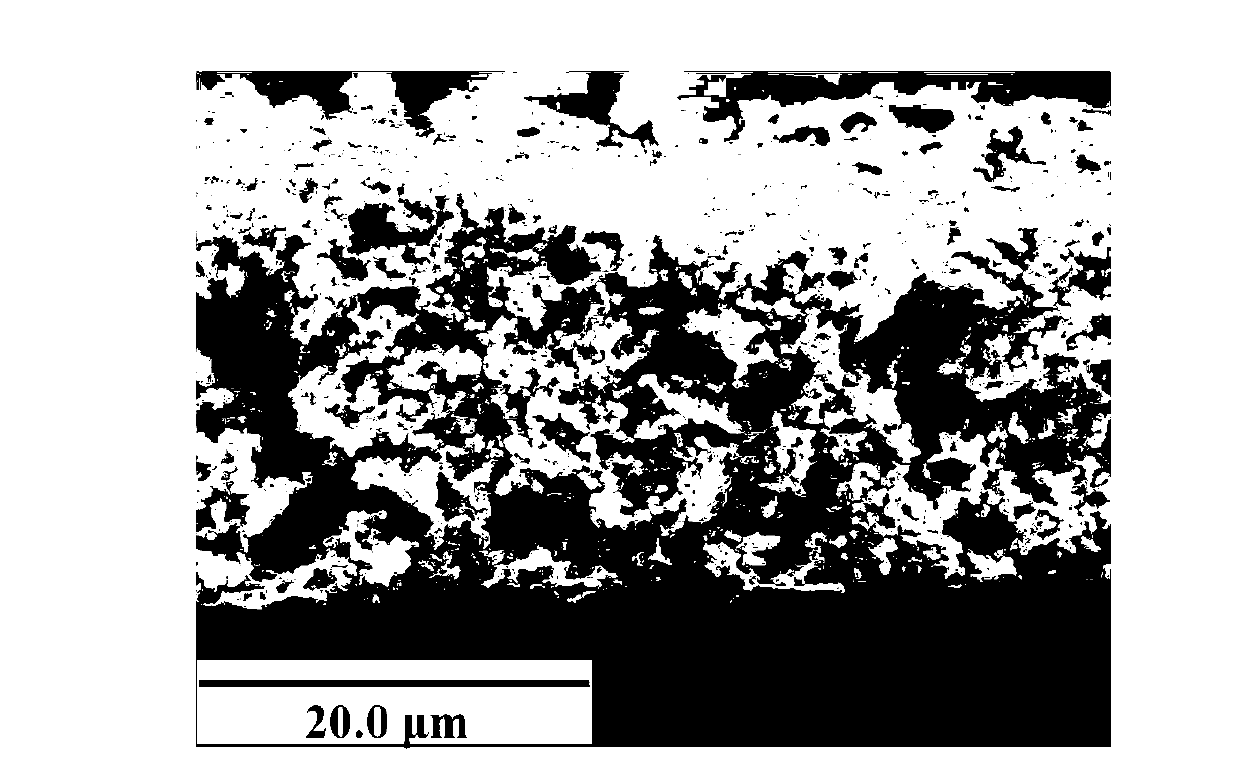

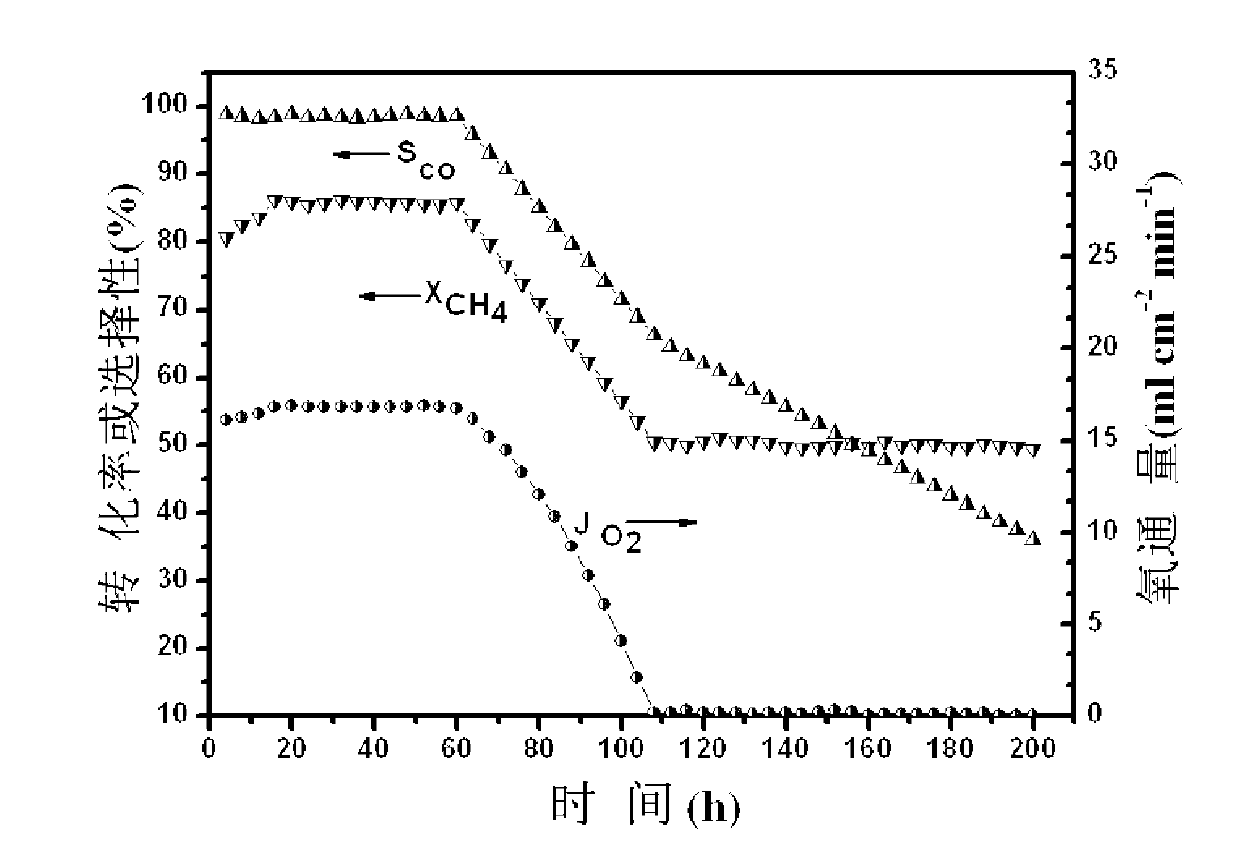

[0035] Dense layer material is 0.5wt%Nb 2 o 5 Doped SrCo 0.8 Fe 0.2 o 3-δ(SCF), the porous layer is Ba 0.3 Sr 0.7 Fe 0.9 Mo 0.1 o 3-δ (BSFM). SCF and BSFM mixed conductor materials were prepared by citric acid-EDTA complexation method, Nb 2 o 5 Doped SCF (SCFNb) was synthesized by a solid-phase method. The particle sizes of BSFM and SCFNb powder particles are 500nm and 260nm, respectively. The dense SCFN layer is a sheet structure with a thickness of 1 mm. Polyvinyl alcohol is used as a binder in the process of preparing the green body, and the content is 5%. 8.41wt.% BSFM powder, 6.43wt.% glycerol, 18.91wt.% ethylene glycol, 60wt.% isopropanol and 6.25wt.% terpineol were mixed to obtain a suspension for preparing a porous BSFM layer. The suspension is sprayed on one side surface of the dense SCFNb membrane by spraying method. The sprayed double-layer film was kept at 1000°C for 2 hours at a heating rate of 2°C / min, and then cooled at a rate of 2°C / min. The desi...

Embodiment 2

[0037] Dense layer material is Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ , Prepared by improved citric acid method. The porous layer is a dual-phase material 40wt.%Pr 0.6 Sr 0.4 FeO 3-δ -60wt.%Ce 0.9 PR 0.1 o 2-δ , prepared by solid-phase reaction method. The particle diameters of the dense layer and the porous layer are 100nm and 150nm, respectively, and the thicknesses are 2.0mm and 10μm, respectively. Polysulfone was used as a binder in the process of preparing the dense layer green body with a content of 1.2%. 5.68wt.% of 40wt.%Pr 0.6 Sr 0.4 FeO 3-δ -60wt.%Ce 0.9 PR 0.1 o 2-δ The powder, 6wt.% glycerin, 40.3wt.% ethanol, 40wt.% polyvinylpyrrolidone and 8.02wt.% epoxy resin were mixed to obtain a suspension for preparing the porous layer. Apply the suspension to the dense Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ one side of the diaphragm. The double-layer film after spraying was kept at 900°C for 5h at a heating rate of 5°C / min, and then cooled at a rate of 5°C / min...

Embodiment 3

[0039] Dense layer material is 3wt.%ZrO 2 Doped SrCo 0.8 Fe 0.2 o 3-δ , prepared by solid phase reaction method, its particle size is 500nm. The material of the porous layer is the ionic electronic material La 0.85 Ce 0.1 Ga 0.3 Fe 0.65 al 0.05 o 3-δ and proton-electron mixed conductor material BaCe 0.95 Y 0.05 o 3-δ . The two are synthesized by the improved citric acid method, and the particle sizes are 50nm and 60nm respectively. The dense layer is prepared by isostatic pressing into a sheet-type green body with a thickness of 2 mm, wherein the binder is polyvinyl alcohol with a content of 10%. After calcining, a sheet-like dense layer is obtained. The proportion of the porous layer suspension is 9.5wt.% porous layer powder, 8.5wt.% glycerin, 50.5wt.% ethylene glycol, 25wt.% polyvinylpyrrolidone and 6.5wt.% polysulfone. La 0.85 Ce 0.1 Ga 0.3 Fe 0.65 al 0.05 o 3-δ and BaCe 0.95 Y 0.05 o 3-δ Porous layer, the thicknesses of the two porous layers are 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com