Lignin dispersant for phenol-water coal water slurry, and preparation method and application thereof

A technology of coal water slurry and dispersant, which is applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of poor stability and low efficiency of dispersant, and achieve good stability, excellent performance-price ratio, and excellent The effect of water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

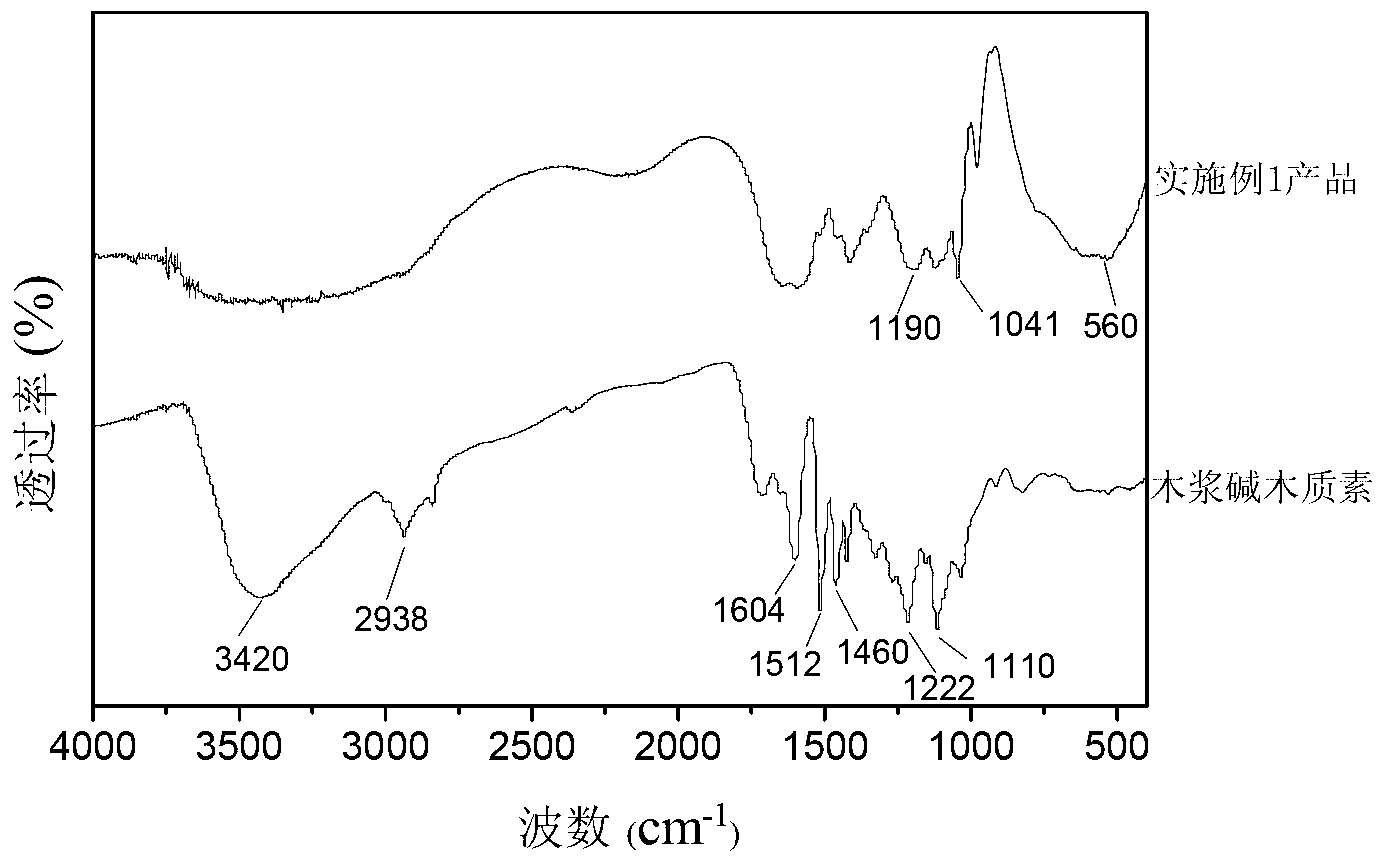

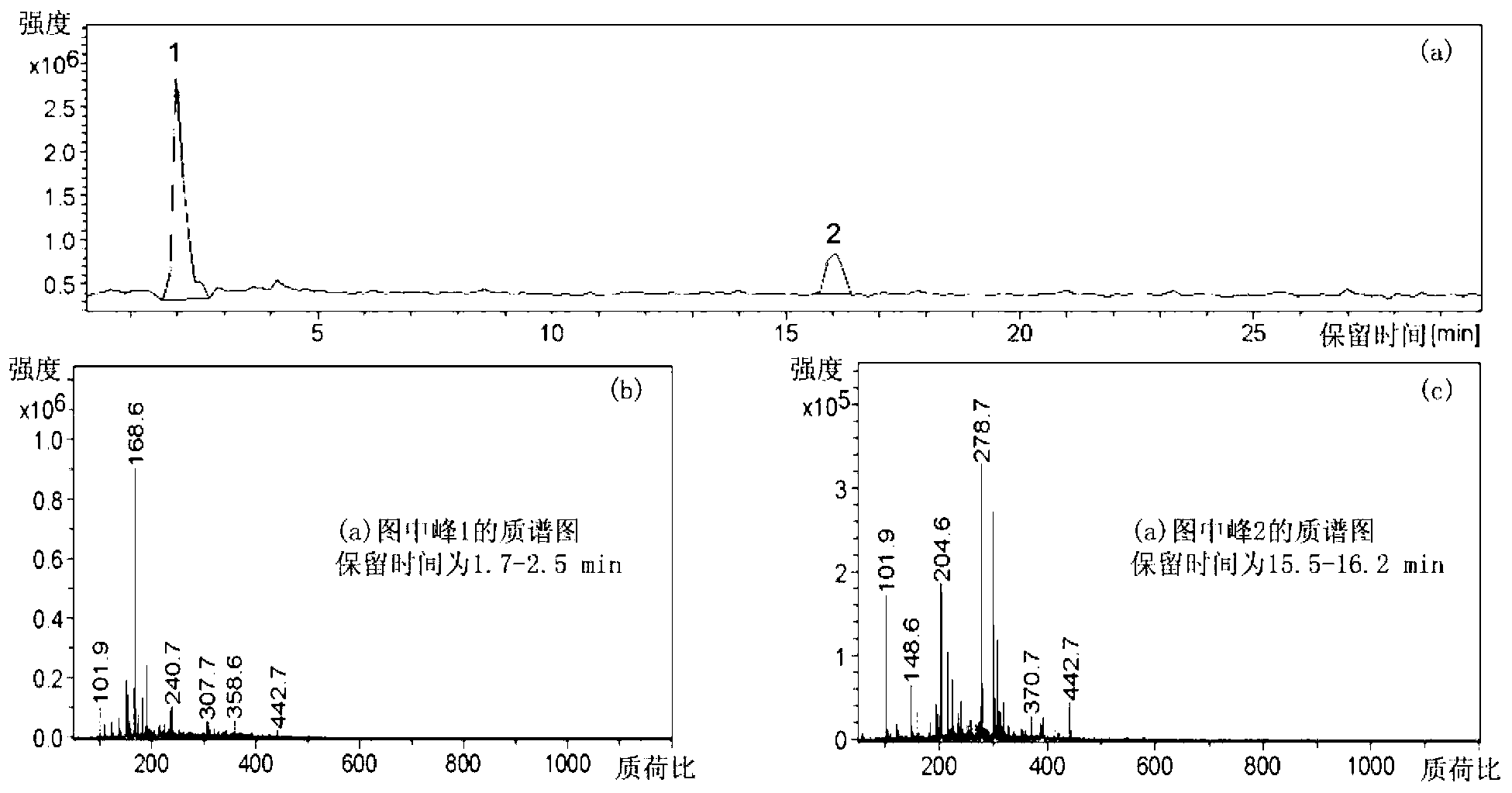

[0039] Dissolve 100g of wood pulp alkali lignin solid in water, adjust the pH value to 10 with NaOH with a concentration of 30% by weight under stirring, and prepare an aqueous solution with a concentration of 45% by weight, heat it to 80°C while stirring, and add 5g Sodium sulfamate and 5g sodium sulfite were reacted for 1 hour, then 10g formaldehyde was added, and methylolation reaction was carried out for 1 hour to obtain hydroxymethylsulfonated alkali lignin;

[0040] Dissolve 10g of dipotassium hydrogen phosphate and 5g of sodium dihydrogen phosphate in water to prepare a solution with a concentration of 20% by weight, add 10g of epichlorohydrin, heat to 30°C, and react for 100 minutes to obtain hydroxypropyl phosphate compound;

[0041] Mix the hydroxymethylsulfonated alkali lignin and hydroxypropyl phosphate compound obtained by the reaction, adjust the pH to 11 with NaOH with a concentration of 30% by weight, heat up to 85°C, and then add 20g of benzaldehyde to carry o...

Embodiment 2

[0043] Take 100g reed alkali lignin solid and dissolve it in water, adjust the pH value to 9 with NaOH with a concentration of 30% by weight under stirring, and prepare an aqueous solution with a concentration of 40% by weight, heat it to 65°C while stirring, add 5g NaOH Sodium bisulfate, reacted for 2 hours, then added 5g of formaldehyde, and carried out methylolation reaction for 3 hours to obtain hydroxymethylsulfonated alkali lignin;

[0044] Dissolve 5g of disodium hydrogen phosphate in water to prepare a solution with a concentration of 35% by weight, add 10g of epichlorohydrin, heat to 50°C, and react for 120 minutes to obtain hydroxypropyl phosphate compounds;

[0045] Mix the hydroxymethylsulfonated alkali lignin and hydroxypropyl phosphate compound obtained by the reaction, adjust the pH to 12.5 with NaOH with a concentration of 30% by weight, heat up to 80°C, and then add 20g of furfural for polycondensation reaction5 After one hour, cool to room temperature; then a...

Embodiment 3

[0047] Dissolve 60g of bamboo pulp alkali lignin and 40g of bagasse alkali lignin solid in water, adjust the pH value to 12 with NaOH with a concentration of 30% by weight under stirring, prepare an aqueous solution with a concentration of 50% by weight, and heat while stirring To 70°C, add 9g sodium bisulfite and 6g ammonium sulfite, react for 1 hour, then add 15g formaldehyde, carry out methylolation reaction for 2 hours, and obtain hydroxymethylsulfonated alkali lignin;

[0048] Dissolve 15g of sodium dihydrogen phosphate in water to prepare a solution with a concentration of 25% by weight, add 5g of epichlorohydrin, heat to 85°C, and react for 30 minutes to obtain hydroxypropyl phosphate compounds;

[0049] Mix the hydroxymethylsulfonated alkali lignin and hydroxypropyl phosphate compounds obtained by the reaction, adjust the pH to 11.5 with NaOH with a concentration of 30% by weight, heat up to 100°C, and then add 10g of glutaraldehyde for polycondensation After reacting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com