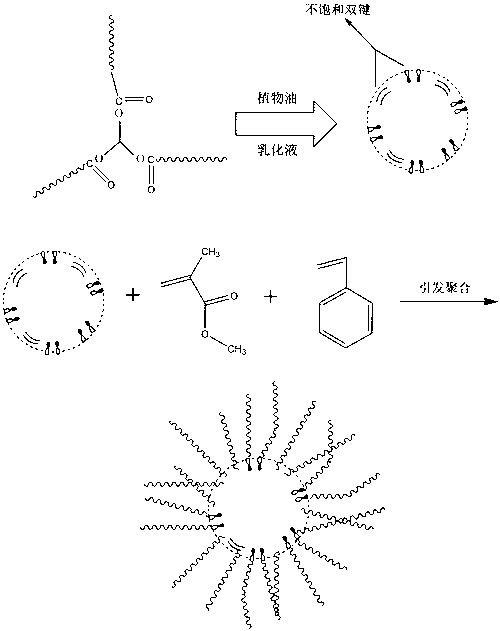

Method for preparing plant oil-based core-shell structural flexibilizer

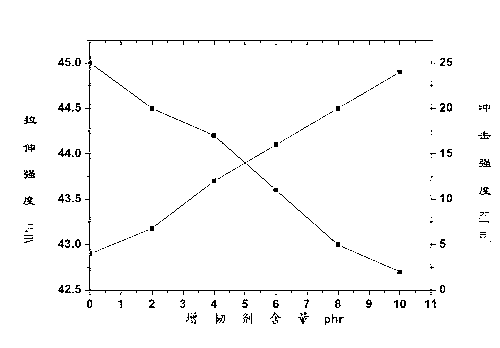

A vegetable oil-based, core-shell structure technology is applied in the field of preparation and modification of functional polymer materials. The effect of less and high toughening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 100 g deionized water, 6 g alkyl polyether soybean oil emulsifier, 3 g sodium dodecylbenzenesulfonate, 0.1 g polyvinyl alcohol, 1 g Potassium persulfate and 100 g liquid soybean oil. Stir at high speed for 10 minutes at room temperature to obtain soybean oil emulsion. Add 5 g of divinylbenzene to the above soybean oil emulsion under agitation, raise the temperature of the reaction system to 75° C., keep the reaction for 4 hours, then cool to room temperature to obtain the inner core emulsion of the toughening agent.

[0033] Add 5 g of potassium persulfate, 10 g of styrene, and 100 g of methyl methacrylate to the above-mentioned toughening agent core emulsion in sequence, and after stirring at a high speed, gradually raise the temperature of the system to 75° C. The temperature of the system further increased to 82°C. After continuing the insulation reaction for 2 hours, the system was cooled to normal temperature to obtain a soybean oil-based toughening agent wit...

Embodiment 2

[0036] Add 100 g of deionized water, 4 g of alkylphenol ethoxylates, 4 g of sodium lauryl sulfate, 2 g of n-octanol, and 0.06 g of hydroxycellulose in a four-neck flask with a heating and stirring device. , 5 g ammonium persulfate and 100 g liquid corn oil. Stir at high speed for 10 minutes at room temperature to obtain corn oil emulsion. 10 g of diene acrylate was added to the above corn oil emulsion under stirring conditions, while raising the temperature of the reaction system to 75° C., keeping the temperature for 4 hours and then cooling to room temperature to obtain a corn oil-based toughener core emulsion.

[0037] Add 10 g of ammonium persulfate, 20 g of styrene, and 100 g of methyl acrylate to the above-mentioned toughening agent inner core emulsion, and after stirring at a high speed, gradually raise the temperature of the system to 75°C. Further increase to 85°C. After continuing the insulation reaction for 1 hour, the system was cooled to normal temperature to ob...

Embodiment 3

[0040] Add 500 g of deionized water, 15 g of alkyl polyethers, 10 g of alkylphenol polyoxyethylene ethers, 10 g of sodium lauryl sulfate, and 10 g of n- Butanol, 0.3 g sodium alginate, 25 g ammonium persulfate, and 500 g liquid peanut oil. Stir at high speed for 10 minutes at room temperature to obtain a peanut oil emulsion. Add 50 g of divinylbenzene to the above peanut oil emulsion under stirring condition, raise the temperature of the reaction system to 75° C., keep the reaction for 4 hours, and then cool to room temperature to obtain a peanut oil-based toughener core emulsion.

[0041]Add 50 g of peroxydicarbonate, 100 g of acrylonitrile, 400 g of vinyl chloride and 100 g of vinylidene chloride to the above-mentioned toughening agent inner core emulsion, and after stirring at a high speed, gradually raise the temperature of the system to 50°C. Heat-preservation and pressure-holding reaction until the pressure drop of the system is obvious, the heat-retention reaction is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com