Super-tough heat-resistant polylactic acid/rubber alloy and preparation method thereof

A technology of rubber alloy and polylactic acid, which is applied in the field of super-tough heat-resistant polylactic acid/rubber alloy and its preparation, can solve the problem that the toughening effect of rubber cannot be fully exerted, and the crystallization performance of PLA and the impact performance of the blend cannot be effectively improved Low-level problems, to achieve the effect of shortening the processing molding cycle, easy industrial production, and improving the crystallinity of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

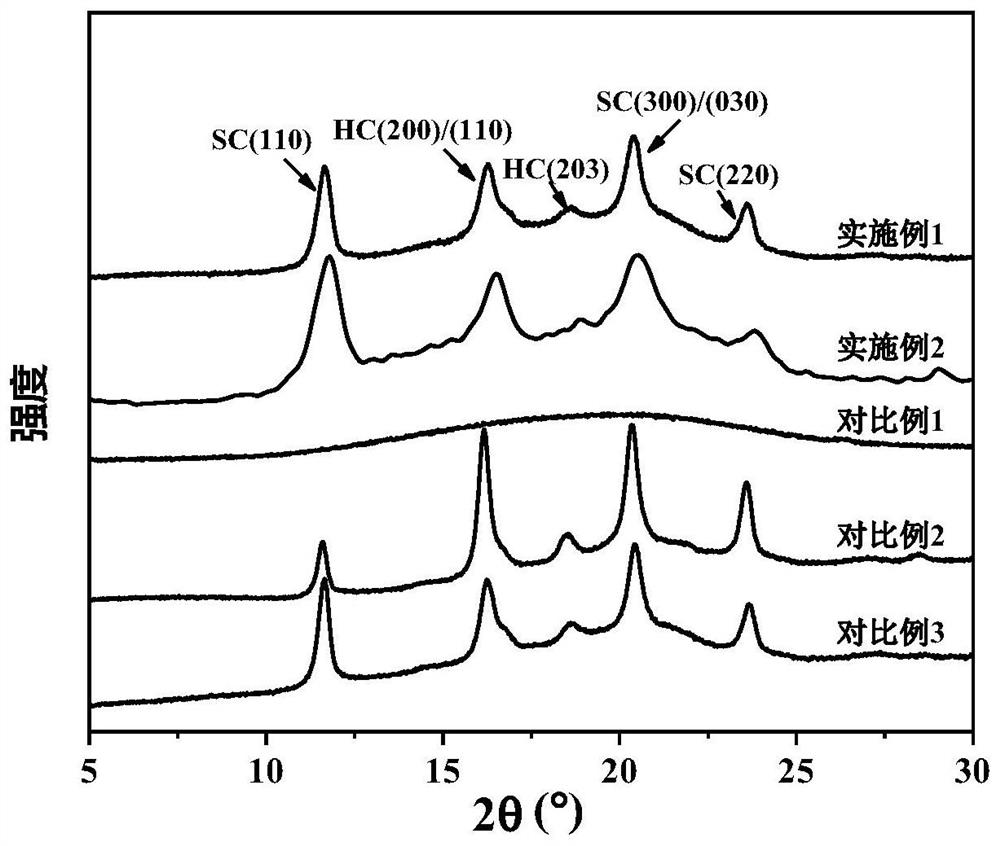

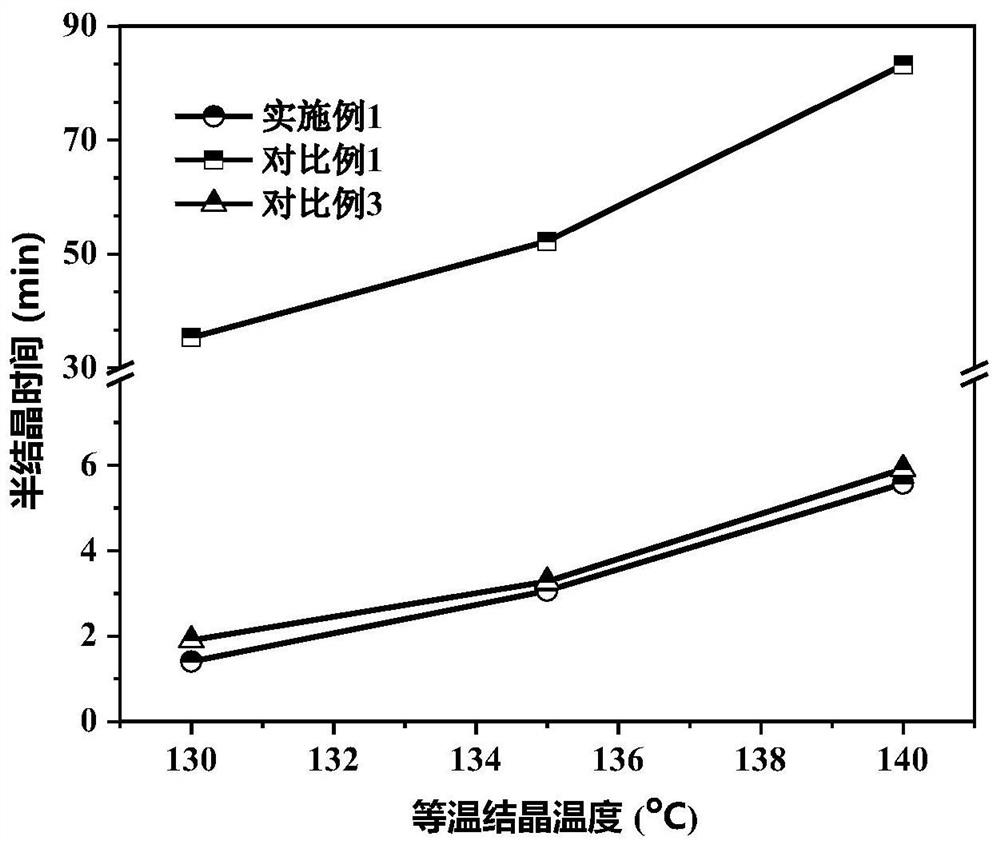

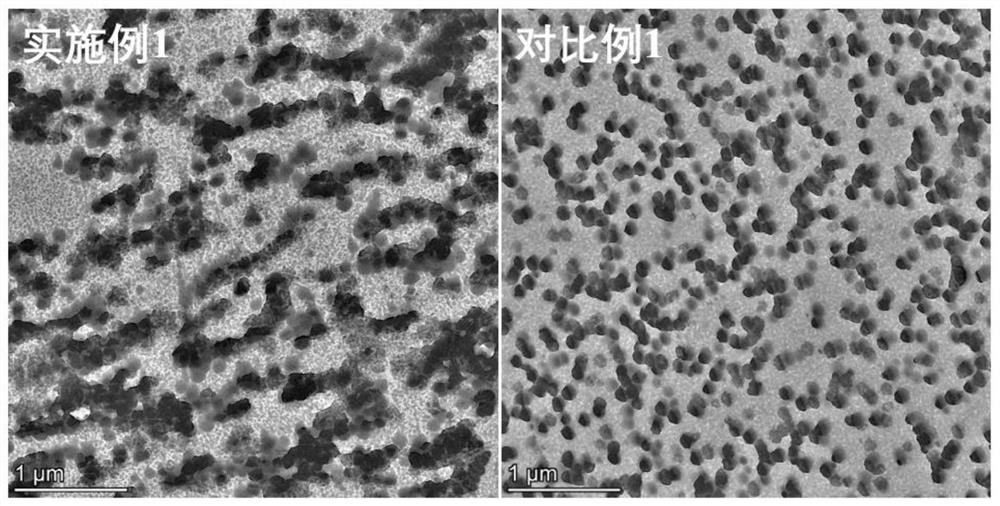

Embodiment 1

[0037] The weight average molecular weight 2.0×10 5 g / mol, linear L-polylactic acid with an optical purity of 98%, and a weight-average molecular weight of 1.0×10 5 g / mol, six-arm D-polylactic acid with an optical purity of 99%, and polybutadiene-polymethyl methacrylate core-shell rubber particles with a particle size of 180nm were pre-mixed evenly, wherein the L-polylactic acid and D-polylactic acid The mass ratio is 100:25, the core-shell rubber particles account for 20% of the mass of the polylactic acid / rubber alloy, and then the premix is melt-blended at a temperature of 200°C for 5 minutes and then granulated to obtain a polylactic acid / rubber alloy material.

Embodiment 2

[0039] The weight average molecular weight is 3.0×10 5 g / mol, linear L-polylactic acid with an optical purity of 95%, and a weight-average molecular weight of 1.6×10 5 g / mol, three-arm D-polylactic acid with an optical purity of 98%, and polybutylacrylate-polymethyl methacrylate core-shell rubber particles with a particle size of 150nm were pre-mixed evenly. The mass ratio is 100:40, the core-shell rubber particles account for 15% of the mass of the polylactic acid / rubber alloy, and then the premix is melt-blended at a temperature of 190°C for 7 minutes and then granulated to obtain a polylactic acid / rubber alloy material.

Embodiment 3

[0041] The weight average molecular weight is 1.6×10 5 g / mol, linear L-polylactic acid with an optical purity of 98%, and a weight-average molecular weight of 2.0×10 5 g / mol, 11-arm star-shaped D-polylactic acid with an optical purity of 98%, and polybutadiene-polymethylmethacrylate core-shell rubber particles with a particle size of 180nm were pre-mixed uniformly, wherein the L-polylactic acid and the D-polylactic acid The mass ratio of polylactic acid is 100:25, the core-shell rubber particles account for 30% of the mass of polylactic acid / rubber alloy, and then the premix is melt blended at a temperature of 200 ° C for 7 minutes and then granulated to obtain polylactic acid / rubber alloy material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com