Preparation method of nanometer calcium hexaboride powder

A technology of calcium hexaboride and powder, applied in the field of preparation of calcium hexaboride, can solve problems such as particle hard agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of nano calcium hexaboride:

[0023] (1) Weigh calcium chloride and sodium borohydride at a molar ratio of 1:6, grind and mix them evenly and put them into the crucible, not exceeding 2 / 3 of the crucible;

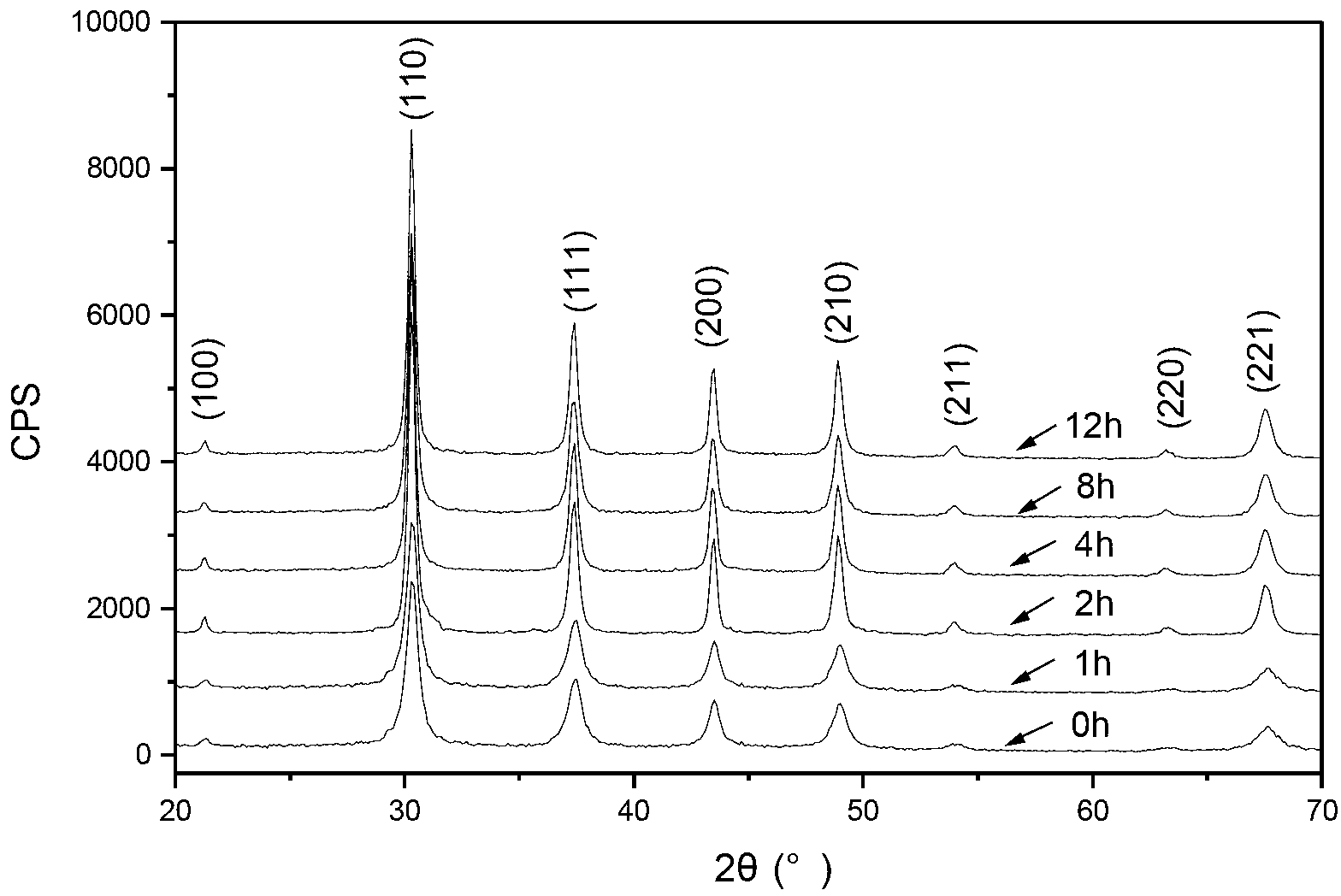

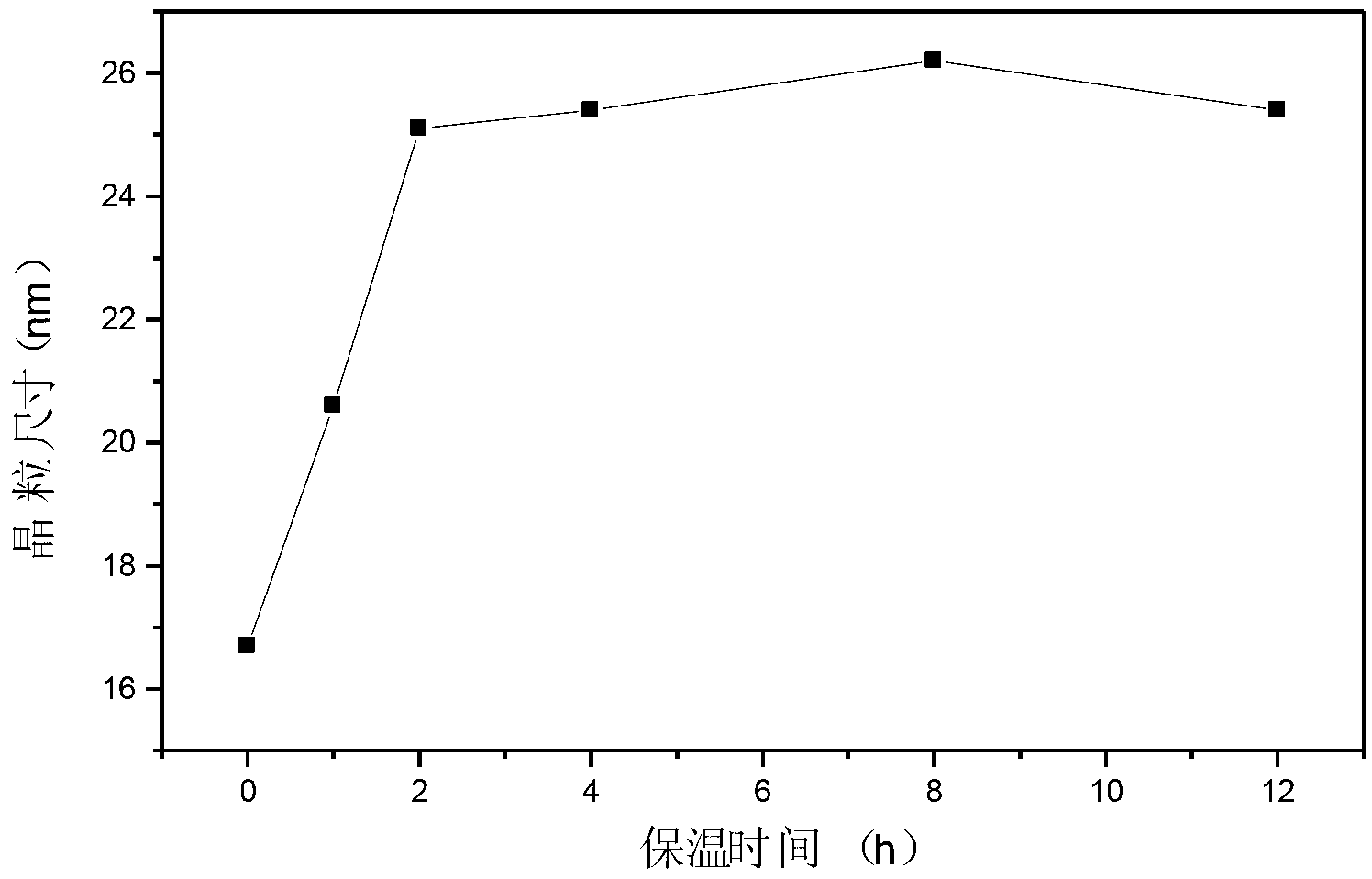

[0024] (2) Place the crucible in a vacuum resistance furnace and keep the working vacuum at 6.67×10 -2 P a , heating at a heating rate of 15°C / min to 530°C and holding for 1 hour;

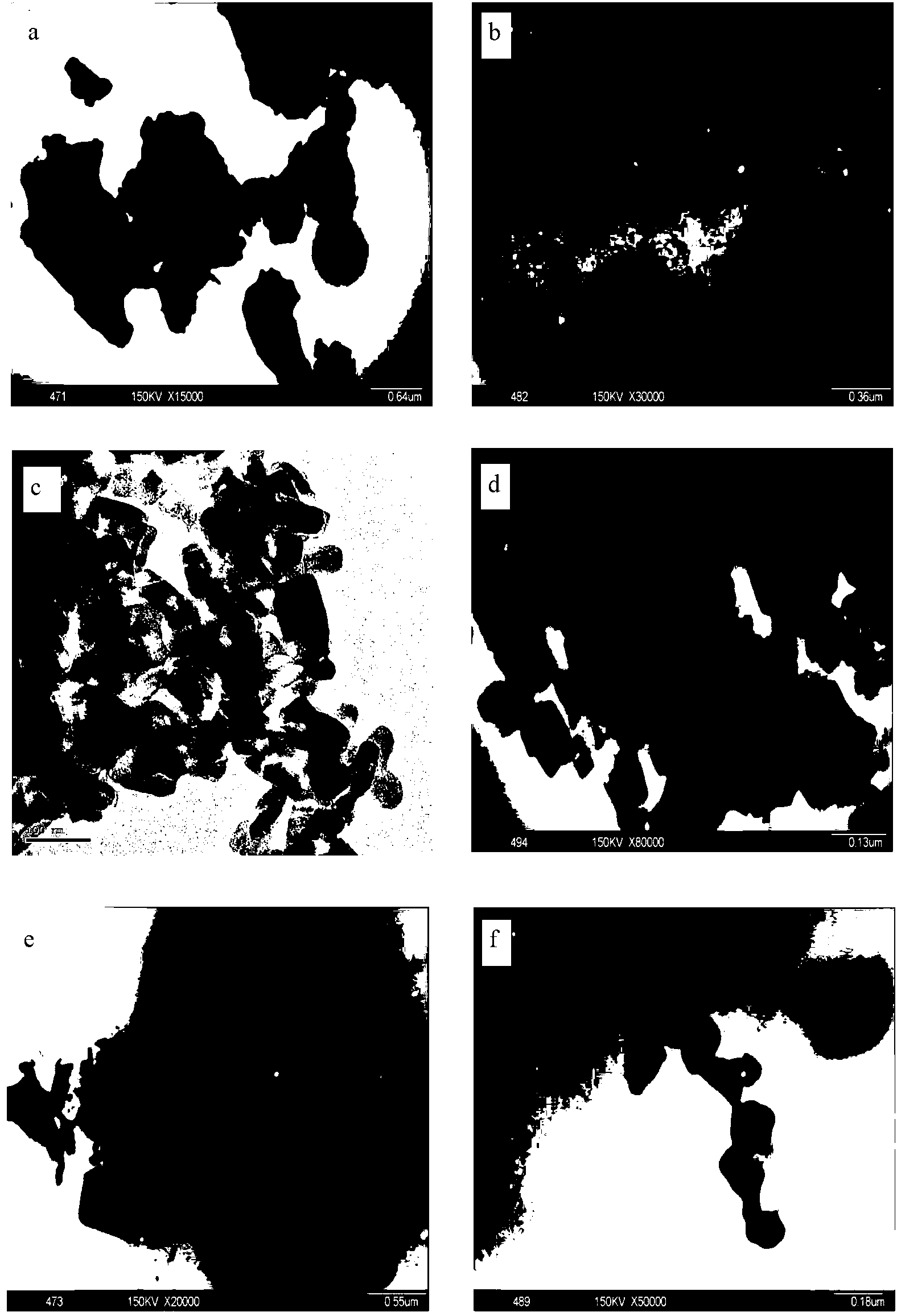

[0025] (3) After the reactant is taken out and ground, first wash away Na in the product with absolute ethanol, and then use three-stage purified deionized water to wash away NaCl and other products. The number of washings is not less than six times. Ultrasonic vibration equipment was used to accelerate the dissolution of by-products during washing, and finally the obtained gray-black powder was placed in a vacuum drying oven at 60°C for 8 hours to heat and dry to obtain the purified final product.

Embodiment 2

[0027] The preparation method of nano calcium hexaboride:

[0028] (1) Weigh calcium chloride and sodium borohydride according to the chemical molar ratio of 1:12, grind and mix them evenly and put them into the crucible, not exceeding 2 / 3 of the crucible;

[0029] (2) Place the crucible in a vacuum resistance furnace and keep the working vacuum at 6.67×10 -2 P a , heating at a heating rate of 15°C / min to 490°C and holding for 4 hours;

[0030] (3) After the reactant is taken out and ground, first wash away Na in the product with absolute ethanol, and then use three-stage purified deionized water to wash away NaCl and other products. The number of washings is not less than six times. Ultrasonic vibration equipment was used to accelerate the dissolution of by-products during washing, and finally the obtained gray-black powder was placed in a vacuum drying oven at 70°C for 6 hours to heat and dry to obtain the purified final product.

Embodiment 3

[0032] The preparation method of nano calcium hexaboride:

[0033] (1) Weigh calcium chloride and sodium borohydride according to the chemical molar ratio of 1:9, grind and mix them evenly and put them into the crucible, not exceeding 2 / 3 of the crucible;

[0034] (2) Place the crucible in a vacuum resistance furnace and keep the working vacuum at 6.67×10 -2 P a , heating at a heating rate of 10°C / min to 500°C and holding for 2 hours;

[0035] (3) After the reactant is taken out and ground, first wash away Na in the product with absolute ethanol, and then use three-stage purified deionized water to wash away NaCl and other products. The number of washings is not less than six times. Ultrasonic vibration equipment was used to accelerate the dissolution of by-products during washing, and finally the obtained gray-black powder was placed in a vacuum drying oven at 60°C for 10 hours to heat and dry to obtain the purified final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com