Chemical method for in-situ control and synthesis of AgCuS/Ag3CuS2 ternary semiconductor photoelectric thin-film material at normal temperature

A ternary compound, photoelectric thin film technology, applied in the field of material chemistry, can solve the problems of strong dependence on reaction vessels, inability to form films directly, polluting the environment, etc., and achieve the effects of controllable film composition, convenient operation and simple reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparatory work: The commercial ITO conductive glass is ultrasonically cleaned with detergent and deionized water for 20 minutes in sequence, and then the volume ratio of ammonia water (mass percentage: 25%): hydrogen peroxide (mass percentage: 30%): deionized water = 80 in the mixed solution of 1:2:5 o C boiled for 30min, and then ultrasonicated with deionized water for 20min again, and the cleaned ITO conductive glass was heated at 80 o C drying conditions. 40nm copper was first sputtered on the ITO surface by magnetron sputtering technology, and then 160nm silver was sputtered. Store the sample in a desiccator for later use;

[0042] 2. Reaction steps: Weigh 0.05g of sulfur powder and put it in a petri dish with a diameter of 100mm, add absolute ethanol, the amount is subject to the sample that can be submerged in step 1, and prepare the copper-silver metal layer prepared in step 1 The ITO conductive glass is placed flat in the petri dish to ensure that the sp...

Embodiment 2

[0045] 1, preparatory work: with embodiment 1.

[0046] 2. Reaction steps: Weigh 0.05g of sulfur powder and put it in a petri dish with a diameter of 100mm, add absolute ethanol, the amount is subject to the sample that can be submerged in step 1, and prepare the copper-silver metal layer prepared in step 1 Place the ITO conductive glass flat in the petri dish, ensure that the sputtered metal layer is upward, avoid direct contact with the sulfur powder, place the petri dish in a stable place, at 40 o Reaction under C conditions for 25 minutes;

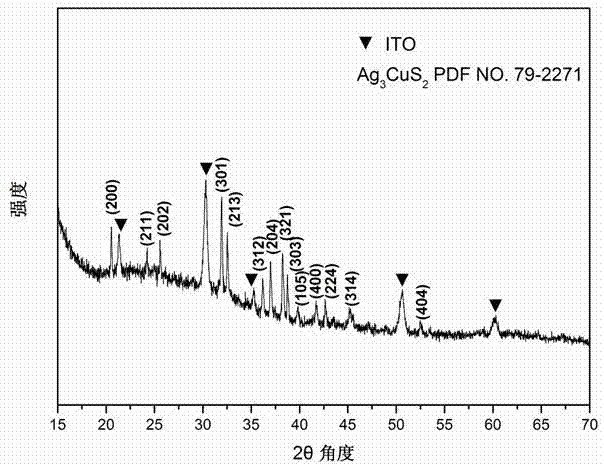

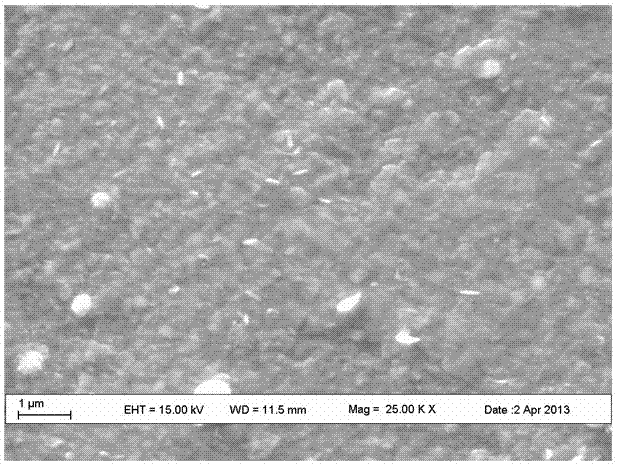

[0047] 3, aftertreatment: with embodiment 1, obtain Ag 3 CuS 2 Sulfur-copper-silver film samples. The color of the product is gray-black, and the microstructure under the scanning electron microscope is granular crystals. Scanning electron microscope photos see ( diagram 2-1 ), XRD results see ( Figure 2-2 ).

Embodiment 3

[0049] 1, preparatory work: with embodiment 1.

[0050] 2. Reaction steps: Weigh 0.05g of sulfur powder and put it in a petri dish with a diameter of 100mm, add absolute ethanol, the amount is subject to the sample that can be submerged in step 1, and prepare the copper-silver metal layer prepared in step 1 Place the ITO conductive glass flat in the petri dish, ensure that the sputtered metal layer is upward, avoid direct contact with the sulfur powder, place the petri dish in a stable place, and wait for 18 o Reaction under C conditions for 2.5 hours;

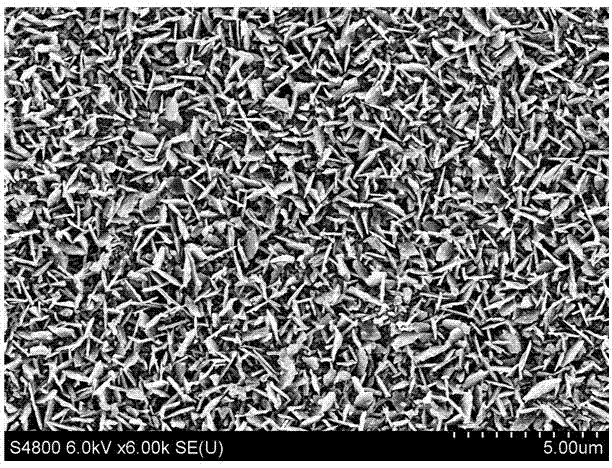

[0051] 3, aftertreatment: with embodiment 1, obtain Ag 3 CuS 2 Sulfur-copper-silver film samples. The color of the product is gray-black, and the microstructure under the scanning electron microscope is flaky nanocrystals. Scanning electron microscope photos see ( Figure 3-1 ), XRD results see ( Figure 3-2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com