Method for monitoring height of step formed by photosensitive mask etched silicon carbide material in real time

A step height, real-time monitoring technology, applied in semiconductor/solid-state device testing/measurement, etc., to ensure device performance and improve process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

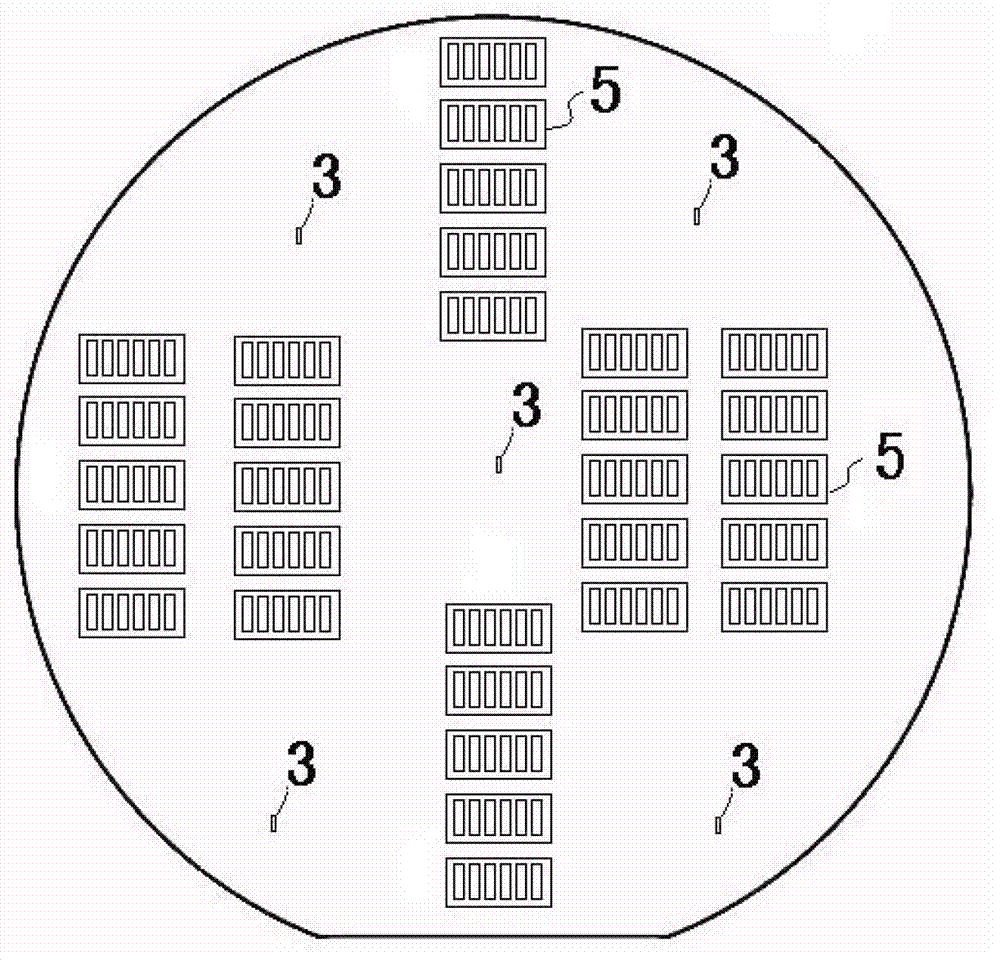

[0029] A silicon carbide photosensitive mask etching method for real-time monitoring of step height, the specific steps are as follows:

[0030] 1. Use an acid solution to clean the silicon carbide material 1; the acid solution uses hydrochloric acid and pure water, and the weight ratio of hydrochloric acid and pure water is 1:5; the silicon carbide material 1 is a silicon carbide epitaxial wafer; figure 1 shown

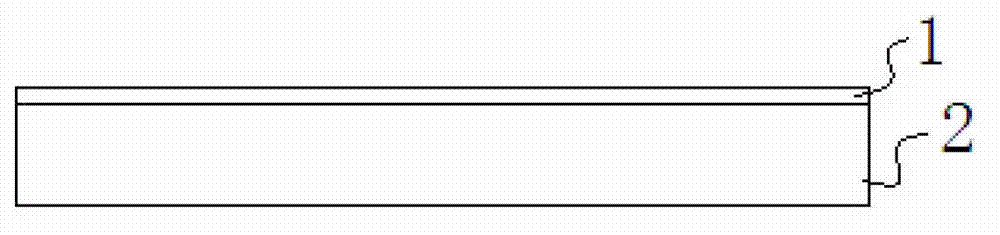

[0031] 2. Coating the adhesive and photosensitive mask layer 2 on the silicon carbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com