Preparation method of thin film transistor, thin film transistor, and array substrate

A thin-film transistor and composite thin-film technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of asynchronous film formation, matching of lithography processes, and industrialization of organic thin-film transistors, etc. Film differences, the effect of ensuring device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

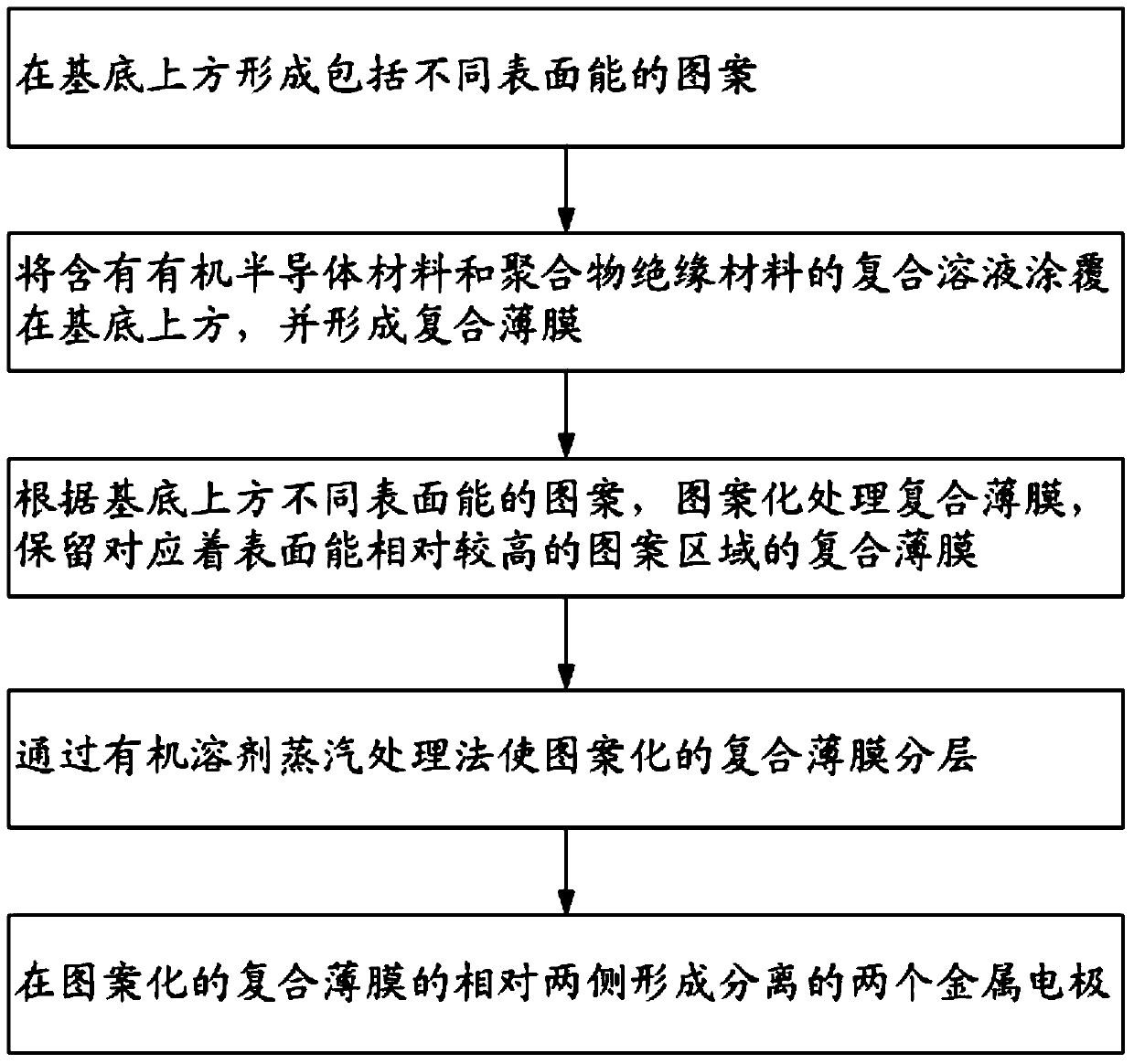

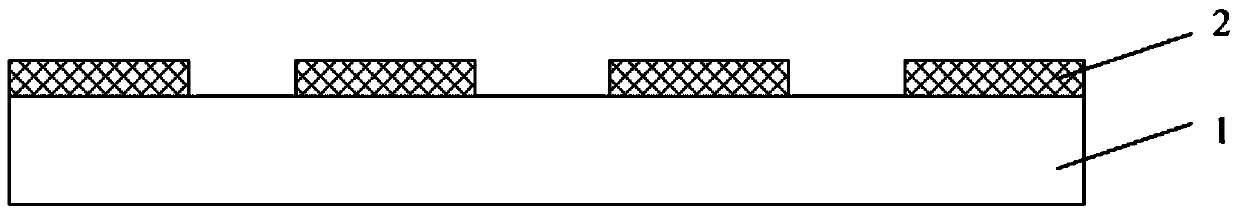

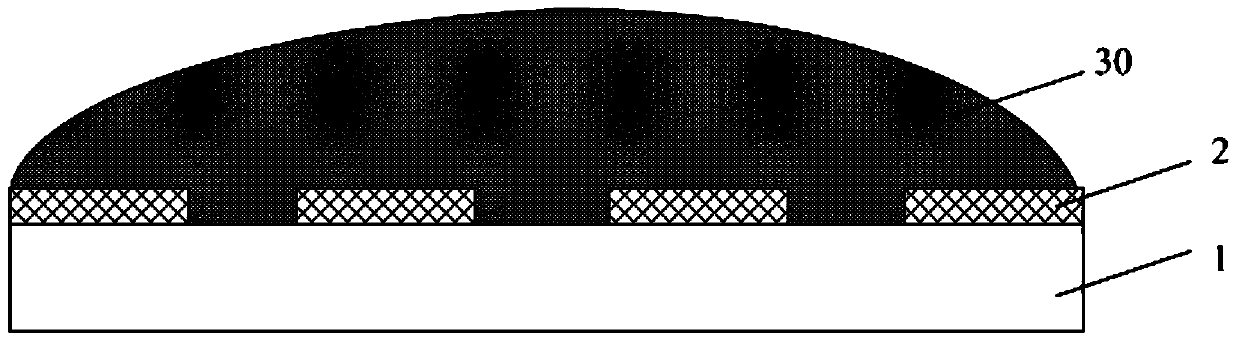

[0067] This embodiment provides a thin film transistor manufacturing method and a thin film transistor correspondingly formed by using the thin film transistor manufacturing method, and the thin film transistor is an organic thin film transistor. The preparation method of the thin film transistor is by using a silicon wafer with a silicon dioxide insulating layer as a substrate, using the silicon wafer as the grid of an organic thin film transistor device, and the silicon dioxide insulating layer of the silicon wafer is insulated from the polymer formed by the polymer insulating material. The layer serves as the gate insulating layer of the organic thin film transistor device, the organic semiconductor layer serves as the active layer of the organic thin film transistor device, and subsequently forms the source electrode and the drain electrode of the organic thin film transistor device. The film formation synchronization between the active layer patterns of the organic thin fi...

Embodiment 2

[0131] This embodiment provides an array substrate, which includes the organic thin film transistor in Embodiment 1.

[0132] The array substrate can be arranged with a plurality of organic thin film transistors prepared by the preparation method of the organic thin film transistors in Embodiment 1, and the plurality of organic thin film transistors are arranged in an array, and further form gate lines and data lines arranged in a criss-cross pattern; Then, the existing process can be continued to prepare and form pixel electrodes and the like to form a liquid crystal type array substrate, or to prepare and form OLED devices and the like to form an OLED type array substrate.

[0133] Wherein, when a plurality of organic thin film transistors are formed on the array substrate, the pattern of the patterned self-assembled monomolecular layer is complementary to the pattern of the gate of the organic thin film transistor.

[0134] The array substrate can be prepared to form OLED d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com