A kind of acetylation modification processing method of poplar wood powder

A treatment method, acetylation technology, applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of high energy consumption, high cost, long production cycle, etc., and achieve high efficiency, high substitution degree, and low water absorption rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

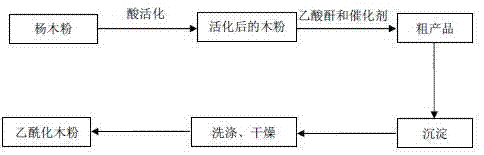

Method used

Image

Examples

Embodiment 1

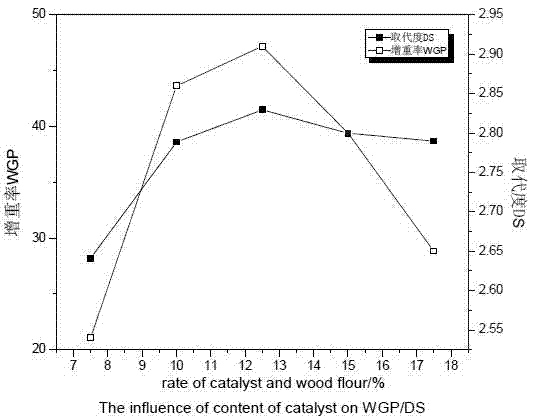

[0033] An acetylation modification treatment method of poplar wood powder: add poplar wood powder and glacial acetic acid to the container according to the mass ratio of poplar wood powder: glacial acetic acid = 1:10, and activate it in an ultrasonic environment with stirring at room temperature Treatment, the ultrasonic power is 300W, and the time is 7min. Then add acetic anhydride and concentrated sulfuric acid to the container according to the mass ratio of wood flour: acetic anhydride: catalyst = 1:5:0.1, place in a microwave reactor for 6 minutes, microwave power 500W, stir at room temperature for 20 minutes after microwave treatment. The reacted wood powder was washed with deionized water and suction-filtered to obtain a filter cake, which was dried in an oven at 105° C. for 12 hours to obtain acetylated wood powder.

Embodiment 2

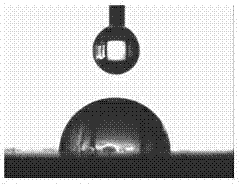

[0035] A method for acetylation modification of poplar wood powder: add poplar wood powder and glacial acetic acid to the container according to the mass ratio of poplar wood powder: glacial acetic acid = 1:15, and activate it in an ultrasonic environment with stirring at room temperature For processing, the ultrasonic power is 500W, and the time is 5min. Then add acetic anhydride, acetic anhydride and perchloric acid into the container according to the mass ratio of wood powder: acetic anhydride: catalyst = 1:9:0.08, and place it in a microwave reactor for 7 minutes, with a microwave power of 350W. After microwave treatment Stir at room temperature for 40min. The reacted wood powder was washed with deionized water and suction filtered to obtain a filter cake, which was placed in an oven and dried at 105°C for 12 hours to obtain acetylated wood powder. See Figure 3-b .

Embodiment 3

[0037]An acetylation modification treatment method of poplar wood powder: add poplar wood powder and glacial acetic acid to the container according to the mass ratio of poplar wood powder: glacial acetic acid = 1:12, and activate it in an ultrasonic environment under stirring at room temperature For processing, the ultrasonic power is 600W, and the time is 4min. Then add acetic anhydride, concentrated sulfuric acid and trifluoroacetic acid into the container according to the mass ratio of wood flour: acetic anhydride: catalyst = 1:7:0.15, wherein the ratio of concentrated sulfuric acid and trifluoroacetic acid is 1:1, and place Irradiate in a microwave reactor for 8 minutes, microwave power 300W, and stir at room temperature for 8 minutes after microwave treatment. The reacted wood powder was washed with deionized water and suction-filtered to obtain a filter cake, which was dried in an oven at 105° C. for 12 hours to obtain acetylated wood powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com