Drying method of cupulate compartment tray of paddy plant materials with steam auxiliary and hot air primary

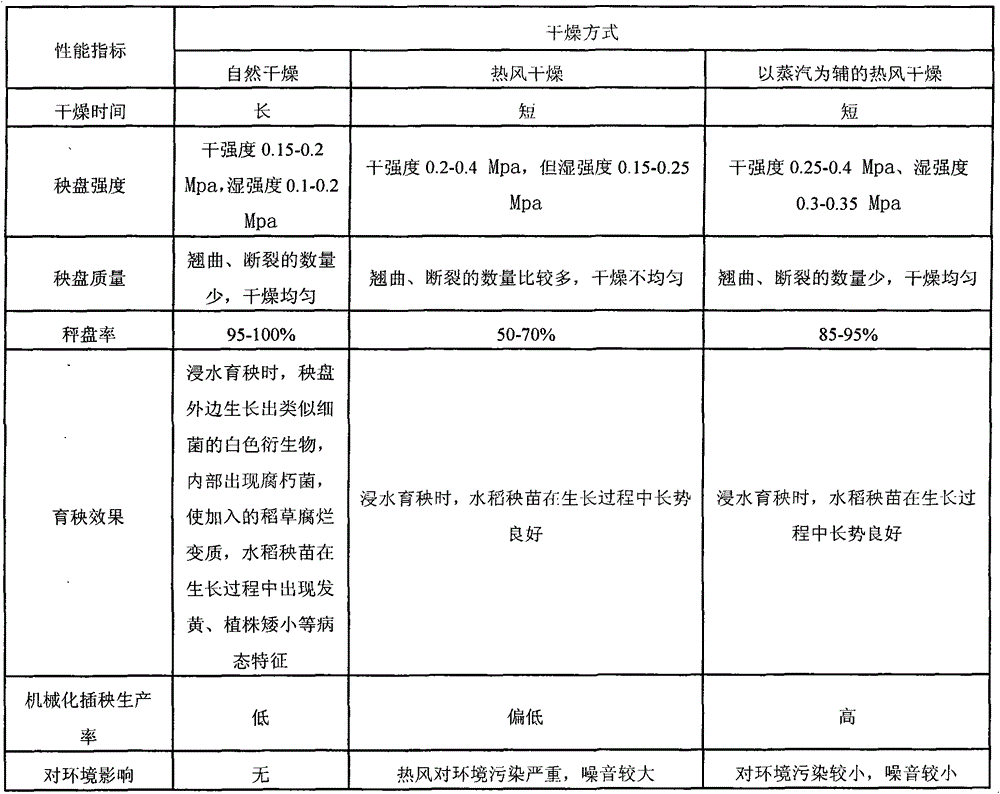

A drying method and technology for raising seedling trays are applied in the drying field of rice vegetative pot raising trays to achieve the effects of good drying strength, good growth of seedlings and good effect of raising seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In March 2010, at Sanjiang Shengli Farm, using this drying process, the seedling trays were dried with steam and hot air, the details are as follows:

[0015] 1. Put the produced 1200 seedling trays in an environment of 10-15°C for 0.5-1 hour, at the same time, preheat the drying device to 100-120°C

[0016] 2. Put the seedling trays on the drying cart, 240 trays per cart, 5 carts in total, push the drying chamber into the drying device with a volume of 24.5m3, close the door of the reaction tank, and continuously dry at 130-140°C under atmospheric pressure. Hot air drying for 0.5-1 hour; (2) Lower the temperature to 120-125°C and continue drying for 4-5 hours. At this stage, steam should be continuously passed into the drying device to keep the relative humidity in the drying device at 75-80 % or so; (3) raise the temperature to 130-135°C, continue to dry for 4-6 hours, and at the same time continuously feed steam into the drying device to keep the relative humidity in...

Embodiment 2

[0018] In July 2010, except that the seedling tray was placed for 0.5 hour at an ambient temperature of 20-30° C., other conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com