Manufacturing method of low-coercive force electromagnetic pure ion cold-rolled sheet

An electromagnetic pure iron and cold-rolled thin plate technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of magnetic performance deterioration, large internal stress, lattice distortion, etc., and achieve high magnetic permeability and excellent magnetic properties , to meet the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

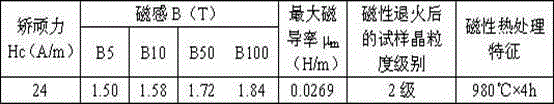

Embodiment 1

[0037] The manufacturing method of the present embodiment comprises the following steps in sequence:

[0038] 1. Fabrication of slabs of optimized composition

[0039] a One-pass molten iron pretreatment, top-bottom double-blown converter smelting and vacuum refining (RH) to control the magnetically harmful C, N, O, S elements and their impurity content, after the molten steel is alloyed, add desulfurizer and rare earth for desulfurization . The amount of desulfurization agent limestone added is not less than 5kg / ton of steel, and the amount of rare earth ferrosilicon added is 1kg / ton of steel. The cycle time after adding desulfurizer and rare earth is ≥12min. The mass percent of the composition of molten steel is:

[0040] C=0.002%; Si=0.011%; M=0.15%; P=0.011%; S=0.002%;

[0041] Al=1.10%; [O] =0.0009ppm; [N]=0.0032ppm;

[0042] The rest is Fe and unavoidable impurities, and the total amount of electrolytic inclusions is 81ppm.

[0043] Vacuum refining method: the high...

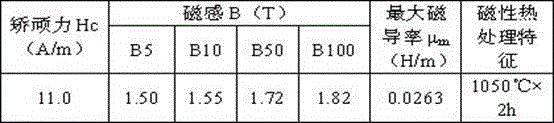

Embodiment 2

[0063] What the present embodiment made was the electromagnetic pure iron cold-rolled thin steel plate, and the present embodiment was the following steps in sequence:

[0064] 1. Fabrication of slabs of optimized composition

[0065] a One-pass molten iron pretreatment, top-bottom double-blown converter smelting and vacuum refining (RH) to control the magnetically harmful C, N, O, S elements and their impurity content, after alloying molten steel, add desulfurizer and rare earth for desulfurization . The amount of desulfurizer limestone added is not less than 5kg / ton of steel (not less than 400kg / furnace), and the amount of rare earth ferrosilicon added is 1kg / ton of steel. The cycle time after adding desulfurizer and rare earth is ≥12min. The mass percent of the composition of molten steel is:

[0066] C=0.0025% Si=0.013 Mn=0. 16% P=0.012%

[0067] S=0.0015% Al=1.10% [O] =0.0010ppm [N]=0.0026ppm,

[0068] The rest is Fe and unavoidable impurities, electrolytic inclusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com