A kind of permanent magnet and its manufacturing method

A permanent magnet, weight percentage technology, applied in the field of permanent magnets and their production, can solve problems such as restricting the development of the aerospace industry, and achieve the effects of high remanence and low coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

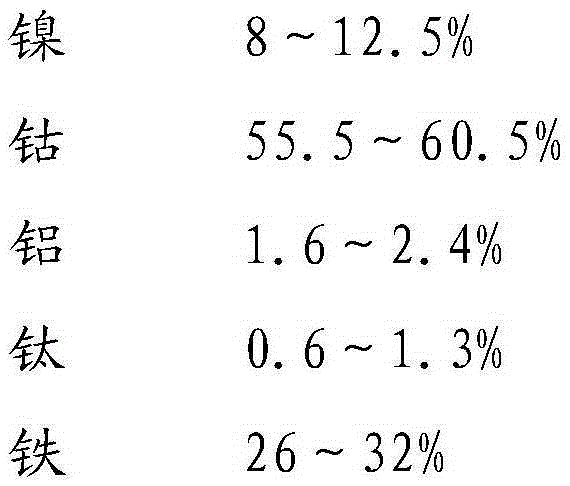

[0024] 1) Fully mix the raw materials according to the ratio of 1# in the table to form a premelt;

[0025] 2) Through vacuum melting and casting, the prepared premelt is melted and cast into ingots;

[0026] 3) Forging and rolling the ingot to make profiles; for the forged profiles, the internal grains are preferentially oriented along the direction of length extension;

[0027] 4) The drawn profile is twice the length of the original profile; the drawn and extruded profile has a preferred orientation of the internal grains along the length direction;

[0028] 5) Carry out heat treatment on the drawn profile, the heat treatment includes the following steps:

[0029] 51) Keep warm at 570°C for 70 minutes;

[0030] 52) Keep warm at 550°C for 130 minutes;

[0031] 53) Keep warm at 510°C for 130 minutes;

[0032] 54) Keep warm at 490°C for 70 minutes.

[0033] A permanent magnet was obtained, the remanence Br was 1400mT, and the coercive force Hc was 2.6kA / m.

Embodiment 2

[0035] 1) Fully mix the raw materials according to the ratio of 2# in the table to form a premelt;

[0036] 2) Through vacuum melting and casting, the prepared premelt is melted and cast into ingots;

[0037] 3) Forging and rolling the ingot to make profiles;

[0038] 3) Forging and rolling the ingot to make profiles; for the forged profiles, the internal grains are preferentially oriented along the direction of length extension;

[0039] 4) Draw the profile to 4 times the length of the original profile; after drawing and extruding the profile, the internal grains are preferentially oriented along the length direction;

[0040] 5) Carry out heat treatment on the drawn profile, the heat treatment includes the following steps:

[0041] 51) Keep warm at 590°C for 50 minutes;

[0042] 52) Insulate at 570°C for 110 minutes;

[0043] 53) Keep warm at 530°C for 110 minutes;

[0044] 54) Keep warm at 510°C for 50 minutes.

[0045] A permanent magnet was obtained, the remanence B...

Embodiment 3

[0047] 1) Fully mix the raw materials according to the ratio of 3# in the table to form a premelt;

[0048] 2) Through vacuum melting and casting, the prepared premelt is melted and cast into ingots;

[0049] 3) Forging and rolling the ingot to make profiles; for the forged profiles, the internal grains are preferentially oriented along the direction of length extension;

[0050] 4) Draw the profile to 3 times the length of the original profile; after drawing and extruding the profile, the internal grains are preferentially oriented along the length direction;

[0051] 5) Carry out heat treatment on the drawn profile, the heat treatment includes the following steps:

[0052] 51) Keep warm at 580°C for 60 minutes;

[0053] 52) Keep warm at 560°C for 120 minutes;

[0054] 53) Keep warm at 520°C for 120 minutes;

[0055] 54) Keep warm at 500°C for 60 minutes.

[0056] A permanent magnet was obtained, the remanence Br was 1450mT, and the coercive force Hc was 2.9kA / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com