Metal gate field effect transistor and manufacturing method thereof

A technology for field effect transistors and metal gates, which is applied in the field of metal gate field effect transistors and its production, can solve the problems of increasing the aspect ratio and increasing the difficulty of filling metal, so as to reduce parasitic resistance and save process costs , The effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

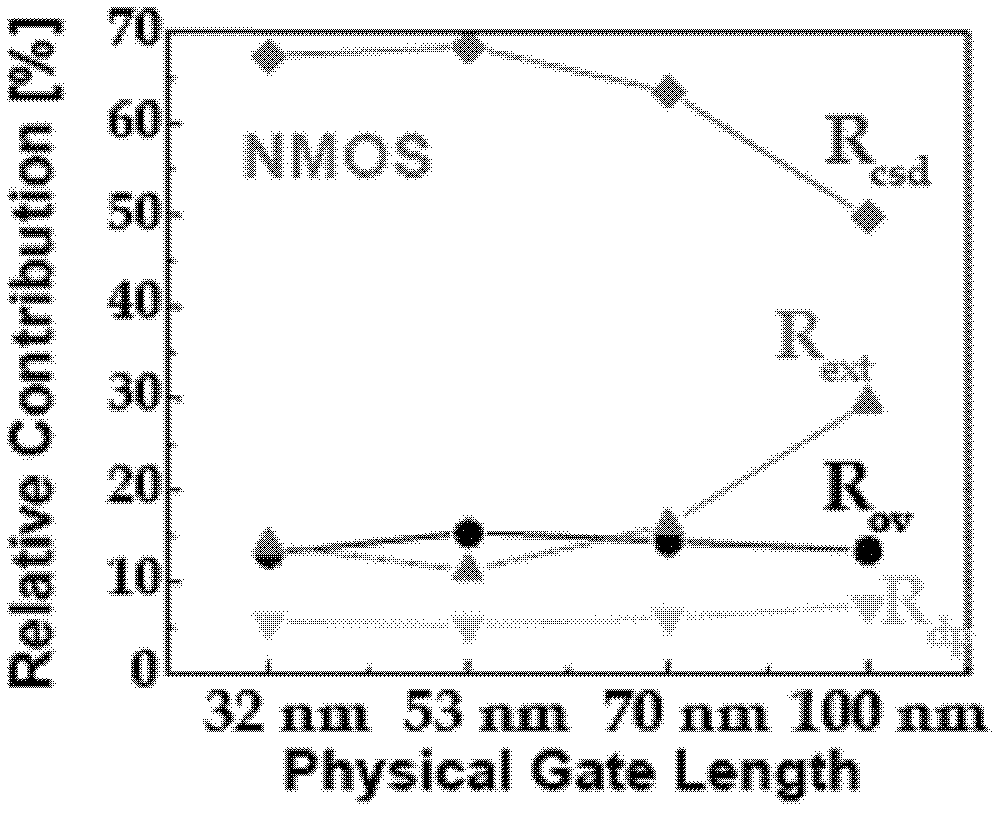

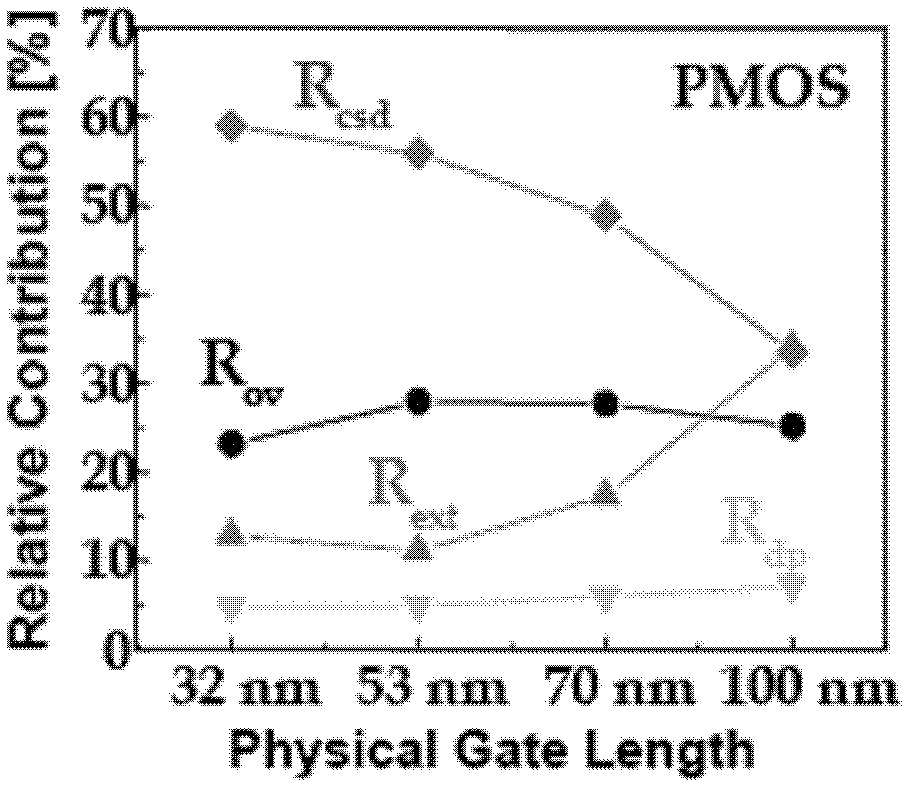

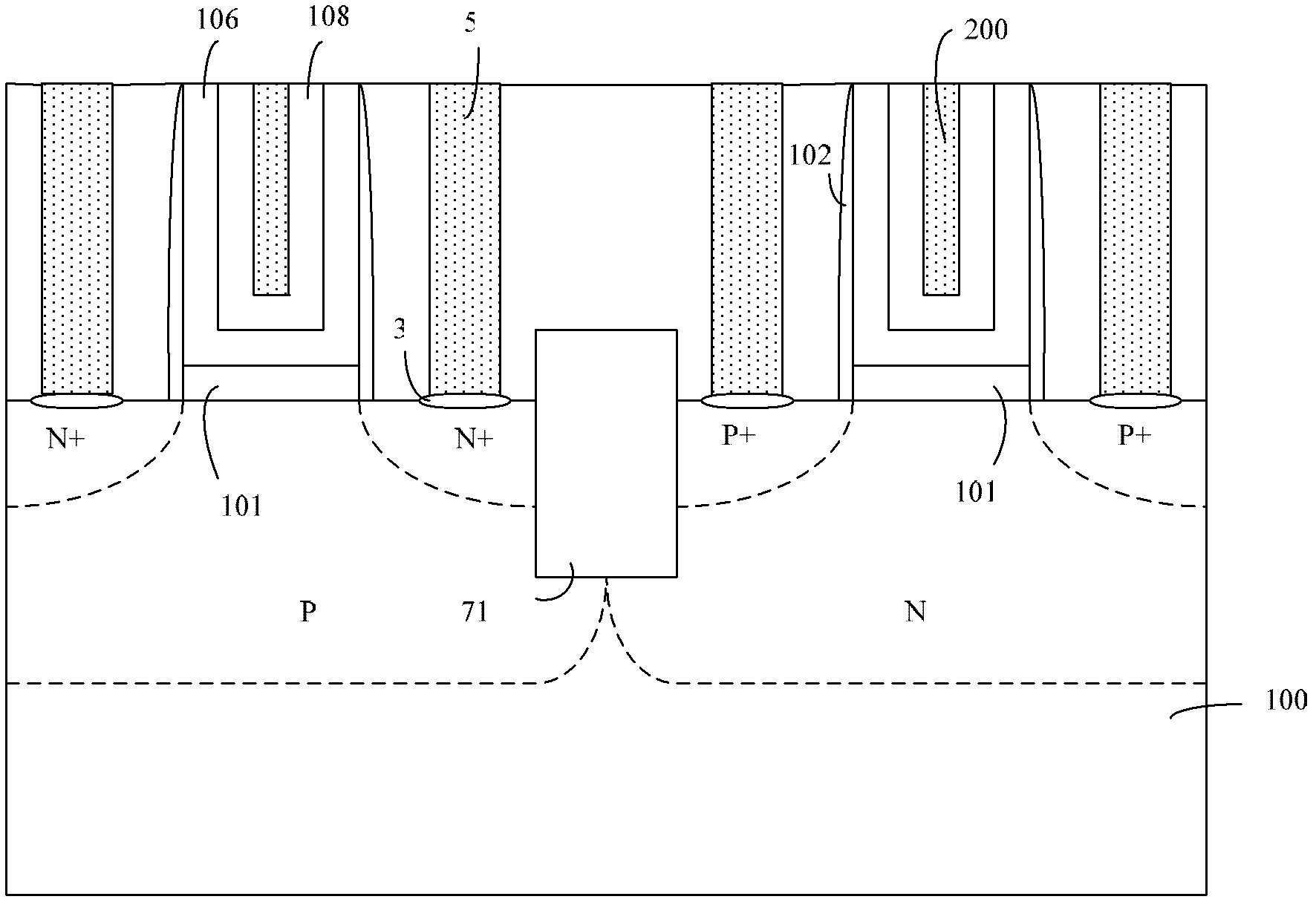

[0027] The present invention provides a method for manufacturing a metal gate field effect transistor, which uses a gate-last process to fabricate a dummy gate, and then forms at least a part of the metal gate stack and the source and drain by electrodeless electroplating (Electroless deposition, electroless plating) contact holes. In the present invention, the last layer of the metal gate and the contact holes of the source and drain electrodes are formed by means of electroless metal plating, so that the trenches and contact holes formed by the metal in the metal gate are used in through holes with high aspect ratios. The metal texture is dense and uniform, and there are no voids and cracks; and the present invention forms the last layer of metal of the metal gate together with the contact hole, which saves process steps, improves process efficiency and saves process cost; at the same time, the present invention The parasitic resistance Rcsd of the contact hole and the drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com