Blue-and-white pigment used in bone china and fabricating technology for blue-and-white bone china

A production process and bone china technology, applied in the field of ceramic materials, can solve the problems of blue and white penetration on bone china, smooth and uniform blue and white patterns of bone china due to the difficulty of coloring, and achieve smooth blue and white patterns, good integration, The effect of preventing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

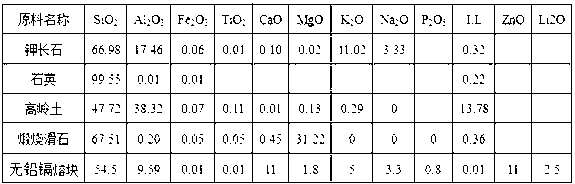

[0032] Preparation of bone china embryo material: 20-35% kaolin, 8-15% potassium feldspar, 5-12% quartz, 40-50% bone char, 2-5% bentonite, sieved through a 325 mesh or finer mesh sieve , zirconium silicate 0.1-0.5%;

[0033] Glaze preparation: 50-65% lead-free cadmium frit, 10-25% quartz, 2-6% calcined talc, 5-10% potassium feldspar, kaolin, sieved through a 325 mesh or finer mesh sieve 8-12%;

[0034] Preparation of coloring material: take ultramarine blue coloring material or cobalt blue coloring material sieved through a 325-mesh or finer mesh sieve;

[0035] B) Mix the total weight of colorant, bone china blank and glaze with the weight of water according to the ratio of 4:6~3:7;

[0036] C) Put the mixture into a fast ball mill and grind it for 20-30 minutes, then pass it through a mesh of 350 mesh or finer, and take the fine powder;

[0037] D) applying the fine powder material on the bisque-fired osteoblast;

[0038] E) Put the plain embryo obtained in step D) into ...

Embodiment 1

[0043] To make a teacup with a blue and white pattern, the preparation steps are as follows:

[0044] 1. Prepare materials

[0045] Take 57kg of the color material sieved by a 325 mesh or finer mesh, including 30kg of cobalt blue material and 27kg of ultramarine blue material; wherein the cobalt blue material contains SiO 2 13.8 kg, Fe 2 o 3 0.6 kg and CoO15.6 kg; ultramarine blue color material contains SiO 2 13.5 kg, Fe 2 o 3 1 kg, TiO 2 0.5 kg and CoO12 kg;

[0046] Take 9.32 kg of bone china raw material sieved through a 325 mesh or finer mesh screen, including 2.5 kg of kaolin, 0.9 kg of potassium feldspar, 1 kg of quartz, 4.5 kg of bone char, 0.4 kg of bentonite and 0.02 kg of zirconium silicate, and mix them as bone china blank;

[0047] Take 18kg of glaze raw materials sieved through a 325 mesh or finer mesh sieve, including 13kg of lead-free cadmium frit, 2kg of quartz, 0.6kg of calcined talc, 1kg of potassium feldspar and 1.4kg of kaolin, and mix them as gla...

Embodiment 2

[0056] To make teacups with blue and white patterns, the specific steps are as follows:

[0057] 1. Prepare materials

[0058] Take 3kg of kaolin, 1.25kg of potassium feldspar, 1.2kg of quartz, 4kg of bone char, 0.5kg of bentonite, and 0.05kg of zirconium silicate sieved through a 325 mesh or finer mesh sieve and mix them as a bone china blank;

[0059] Take 11kg of lead-free cadmium frit, 2.5kg of quartz, 0.5kg of calcined talc, 1.2kg of potassium feldspar, and 1.8kg of kaolin sieved by a 325 mesh or finer mesh sieve as glaze;

[0060] Take 35kg of cobalt blue material, 35kg of ultramarine blue color material, and 3kg of methyl cellulose sieved through a 325 mesh or finer mesh, and mix with the above-mentioned bone china blank and glaze; wherein the cobalt blue material contains SiO 2 17kg and CoO18kg; ultramarine blue pigment contains SiO 2 17.5 kg, Fe 2 o 3 1.05kg, TiO 2 0.7kg and CoO15.75kg;

[0061] 2. Mix the above materials and mix them with 220kg of water to get ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com