High temperature resistance fastening piece and manufacture method thereof

A manufacturing method and fastener technology, which are applied to threaded fasteners, connecting components, bolts, etc., can solve the problems that alloy materials cannot be solid solution strengthened, the manufacturing method is complicated to operate, and the oxidation resistance of fasteners is poor, and the plasticity is achieved. Good, roughness, mechanical strength increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

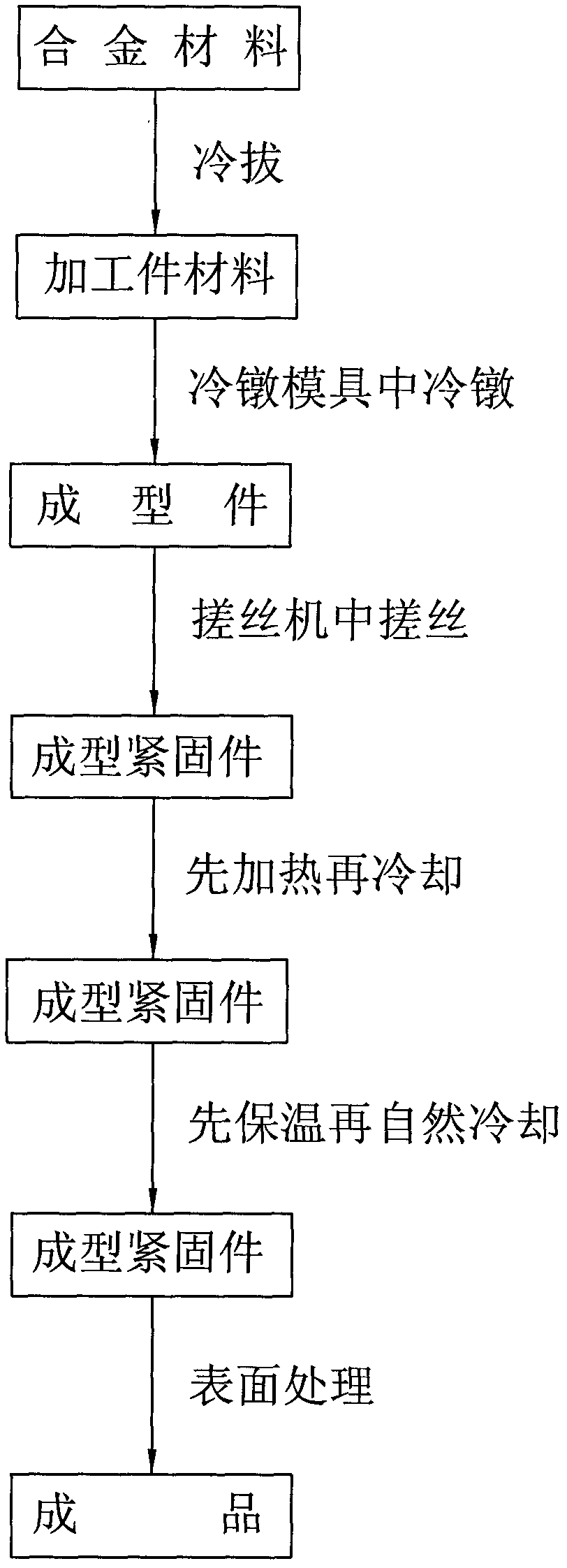

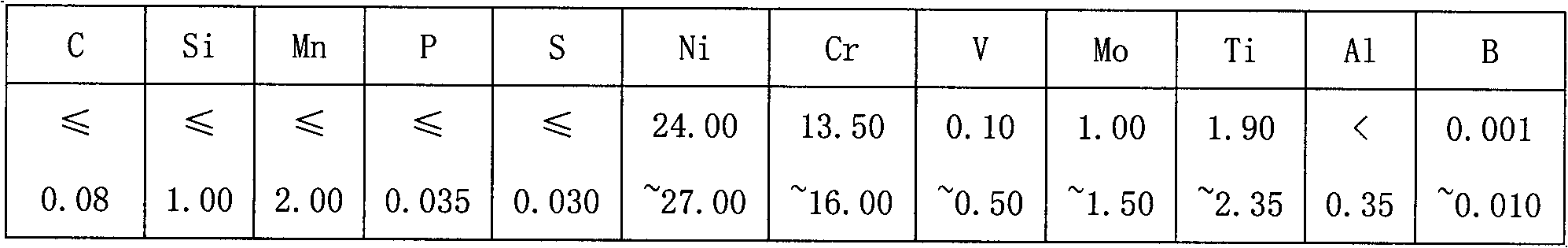

[0023] Embodiment one: if figure 1 As shown, the high-temperature-resistant fastener of this embodiment is made of alloy material, and the composition and content of the alloy material are: carbon 0.06%, silicon 0.8%, manganese 1.8%, phosphorus 0.015%, sulfur 0.01%, Nickel 24%, chromium 13.5%, vanadium 0.1%, molybdenum 1%, titanium 1.9%, aluminum 0.15%, boron 0.001%, iron 56.664%.

[0024] The manufacturing method of the high temperature resistant fastener comprises the following steps:

[0025] Include the following steps:

[0026] 1. Select the alloy material in the above components, place the selected alloy material at room temperature for cold drawing, and cold draw it into the workpiece material of the required specification;

[0027] 2. Heat the workpiece material at a temperature of 890-940°C for 1.5-2.5 hours, then quickly cool the heated workpiece material to room temperature with cold water; or place the workpiece material at 940- Heating at a temperature of 990°C...

Embodiment 2

[0033] Embodiment two: if figure 1 As shown, the high-temperature-resistant fastener of this embodiment is made of alloy material, and the composition and content of the alloy material are: carbon 0.07%, silicon 0.9%, manganese 1.9%, phosphorus 0.025%, sulfur 0.02%, Nickel 25%, chromium 14.5%, vanadium 0.3%, molybdenum 1.25%, titanium 2%, aluminum 0.25%, boron 0.005%, iron 53.78%.

[0034] The manufacturing method of the high temperature resistant fastener comprises the following steps:

[0035] 1. Select the alloy material in the above components, place the selected alloy material at room temperature for cold drawing, and cold draw it into the workpiece material of the required specification;

[0036] 2. Heat the workpiece material at a temperature of 900°C for a holding time of 2 hours, and then quickly cool the heated workpiece material to room temperature with cold water; or, heat the workpiece material at a temperature of 980°C , the holding time is 1 hour; then the hea...

Embodiment 3

[0042] Embodiment three: as figure 1As shown, the high-temperature-resistant fastener of this embodiment is made of alloy material, and the composition and content of the alloy material are: carbon 0.08%, silicon 1%, manganese 2%, phosphorus 0.035%, sulfur 0.03%, Nickel 27%, chromium 16%, vanadium 0.5%, molybdenum 1.5%, titanium 2.35%, aluminum 0.35%, boron 0.01%, iron 49.145%.

[0043] The manufacturing method of the high temperature resistant fastener comprises the following steps:

[0044] 1. Select the alloy material in the above components, place the selected alloy material at room temperature for cold drawing, and cold draw it into the workpiece material of the required specification;

[0045] 2. Heat the workpiece material at a temperature of 950°C for 1.5 hours, then quickly cool the heated workpiece material to room temperature with cold water; or heat the workpiece material at a temperature of 8980°C , the holding time is 1.2 hours; then the heated workpiece materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com