Superfine common glass powder doped active powder concrete and preparation method thereof

A technology of active powder and ordinary glass, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low compressive strength of active powder concrete and high cost of active powder concrete, so as to increase the reactivity, Effect of improving activity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

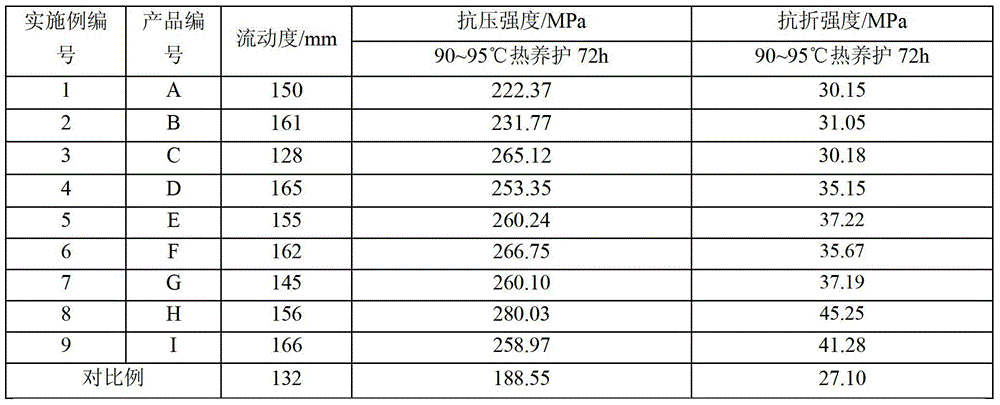

Examples

Embodiment 1

[0046] The active powder concrete A described in this implementation includes 1000g P.O 42.5 ordinary Portland cement, and 100g specific surface area is 450~550m 2 / kg superfine ordinary glass powder, 200g silica fume, 350g quartz powder, 1350g natural river sand, 350g industrial water, 35g water reducing agent and 2.2% steel fiber of the total volume of active powder concrete.

[0047] The preparation method of reactive powder concrete described in the present embodiment is as follows:

[0048] (1) Dissolving the above specific amount of polycarboxylate water reducer in the above specific amount of industrial water to obtain an aqueous solution of polycarboxylate water reducer;

[0049] (2) Pour two-thirds of the total volume of the above-mentioned specified amount of cement, ultra-fine ordinary glass powder and silica fume, and polycarboxylate superplasticizer aqueous solution into the stirring pot in sequence, and stir for 5 minutes;

[0050] (3) Add the specific amount of...

Embodiment 2

[0052] The active powder concrete B described in this implementation includes 1000g P.O 42.5 ordinary Portland cement, 120g specific surface area is 450~500m 2 / kg superfine ordinary glass powder, 210g silica fume, 360g quartz powder, 1270g natural river sand, 370g industrial water, 37g polycarboxylate water reducing agent and 2.5% steel fiber of the total volume of active powder concrete.

[0053] The preparation method of reactive powder concrete described in the present embodiment is as follows:

[0054] (1) Mix the above specific amount of cement, ultra-fine ordinary glass powder, quartz powder and silica fume evenly;

[0055] (2) Mix the above-mentioned specific amount of quartz sand and steel fiber evenly;

[0056] (3) Dissolving the above specific amount of polycarboxylate water reducer in a specific amount of water to obtain an aqueous solution of polycarboxylate water reducer;

[0057] (4) Add two-thirds of the total volume of the polycarboxylate superplasticizer aq...

Embodiment 3

[0061] The active powder concrete C described in this implementation includes 1000g P.O 42.5 ordinary Portland cement, 140g specific surface area is 450~500m 2 / kg superfine ordinary glass powder, 220g silica fume, 370g quartz powder, 1280g natural river sand, 380g industrial water, 38g water reducing agent and 2.0% steel fiber of the total volume of active powder concrete.

[0062] The preparation method of reactive powder concrete described in the present embodiment is as follows:

[0063] (1) Mix the above specific amount of cement, ultra-fine ordinary glass powder, quartz powder and silica fume evenly;

[0064] (2) Mix the above-mentioned specific amount of quartz sand and steel fiber evenly;

[0065] (3) Dissolving the above specific amount of polycarboxylate water reducer in a specific amount of water to obtain an aqueous solution of polycarboxylate water reducer;

[0066] (4) Add two-thirds of the total volume of the polycarboxylate superplasticizer aqueous solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com