Vertical parasitic type plug-and-play (PNP) audion in germanium silicon heterojunction bipolar transistor (HBT) technology and manufacture method

A PNP triode and vertical parasitic technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low emission coefficient of PNP triode, inability to penetrate the germanium-silicon alloy carbon layer, and insufficient cut-off frequency to achieve improvement Effects of parasitic effects, area saving, improvement of current gain coefficient and frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

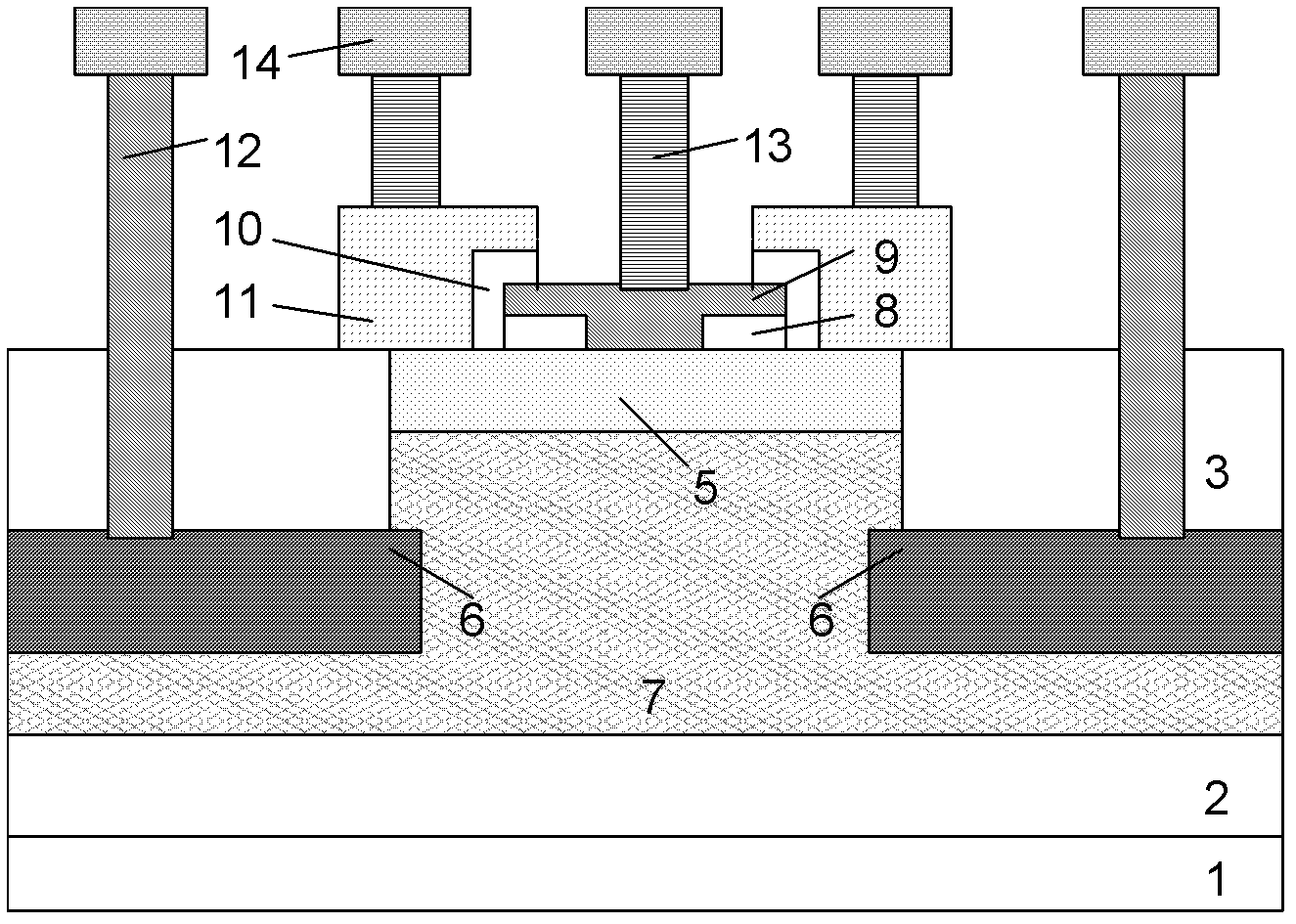

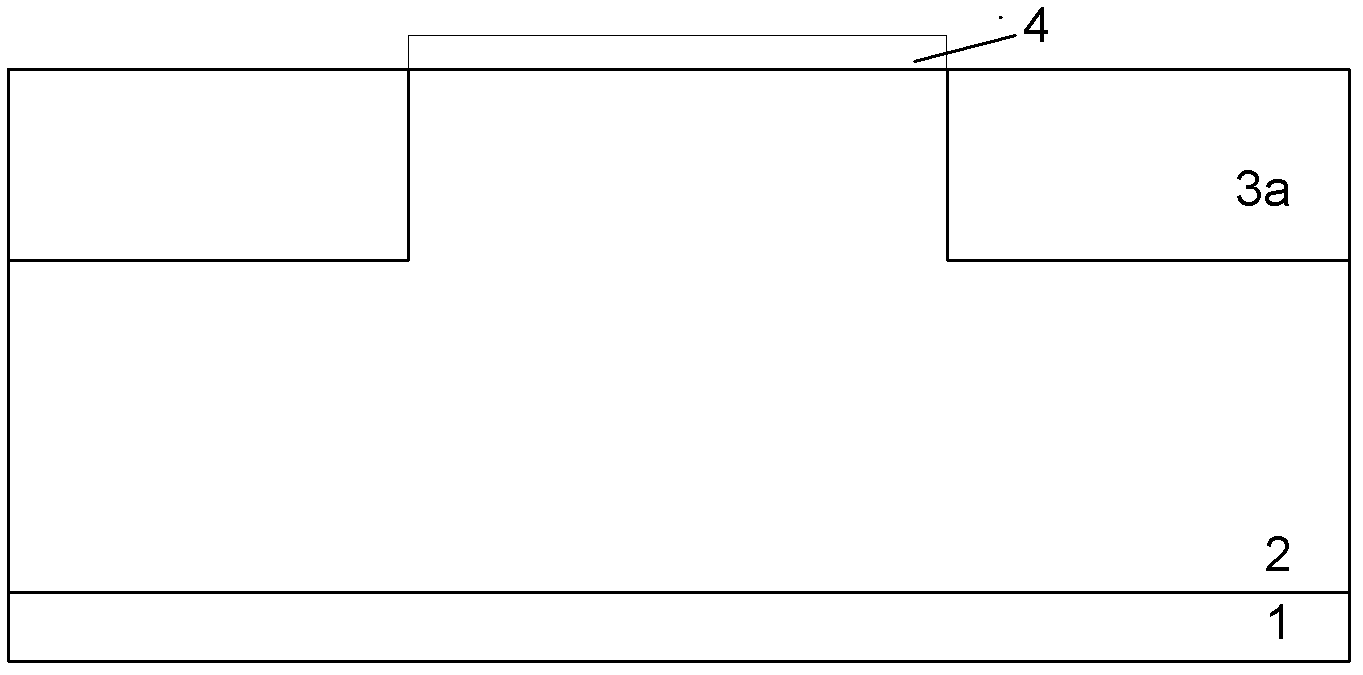

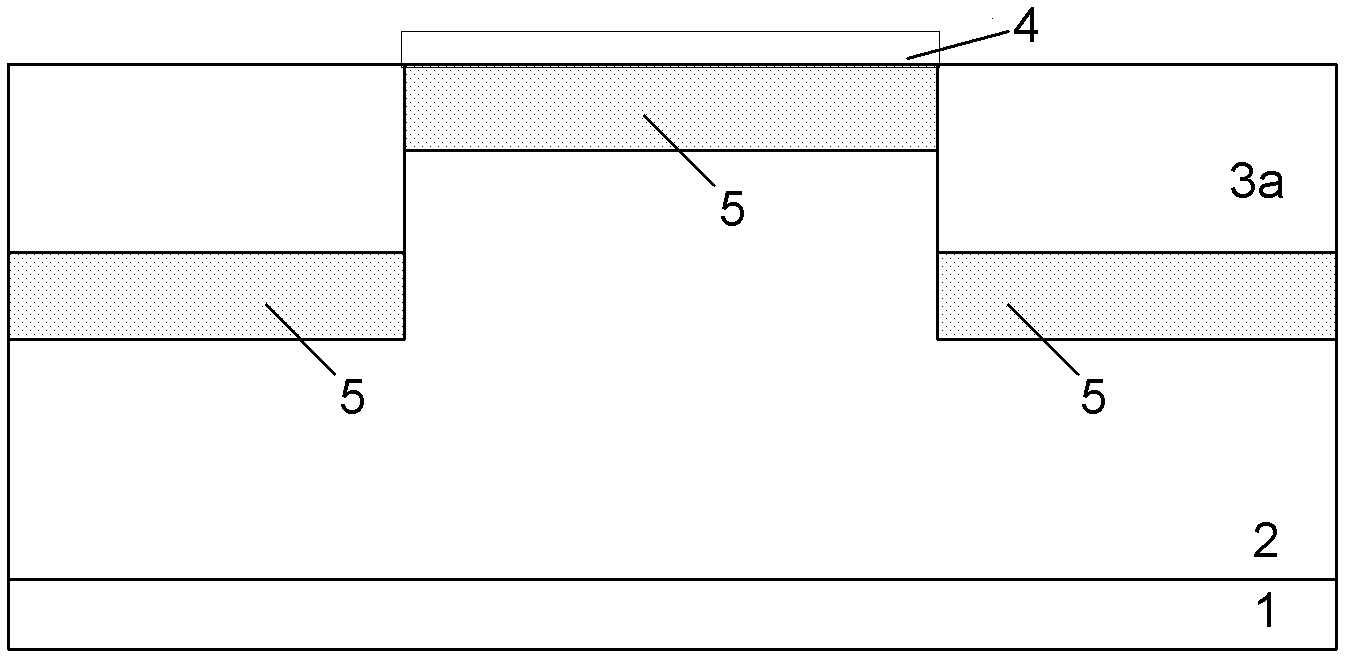

[0043] Such as figure 1 Shown is a schematic structural diagram of a vertical parasitic PNP transistor in the silicon germanium HBT process of the embodiment of the present invention. In the silicon germanium HBT process of the embodiment of the present invention, the vertical parasitic PNP transistor is formed on the P-type silicon substrate 1, and an N-type deep well 2 is formed on the P-type silicon substrate 1, and the active region is composed of a shallow groove field oxygen 3 isolation is shallow trench isolation (STI), including:

[0044] A collector region 7 is composed of a P-type ion implantation region formed in the active region, and the depth of the collector region 7 is greater than or equal to the depth of the bottom of the shallow trench field oxygen 3 . The P-type ion implantation in the collector region adopts the CMOS P-well implantation process in the SiGe HBT process.

[0045] A pseudo-buried layer 6, composed of P-type ion implantation regions formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com