Method for oxidizing agent-aided restoration of failed lithium cobalt oxide under reinforcement of ultrasonic field

A technology of lithium cobalt oxide and oxidant, applied in recycling technology, recycling of waste collectors, electrical components, etc., can solve the problems of strong corrosiveness of reaction equipment, long reaction time, environmental pollution, etc., and achieve good environmental benefits, electrochemical The effect of improved performance and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Select the discarded lithium-ion battery, discharge it and disassemble it to obtain the positive electrode aluminum foil;

[0021] (2) Put the positive electrode aluminum foil into a muffle furnace and calcinate at 380°C for 1.8 hours. After the temperature drops, shake the incinerated aluminum foil to make lithium cobalt oxide fall off from the current collector aluminum foil to obtain black lithium cobalt oxide powder ;

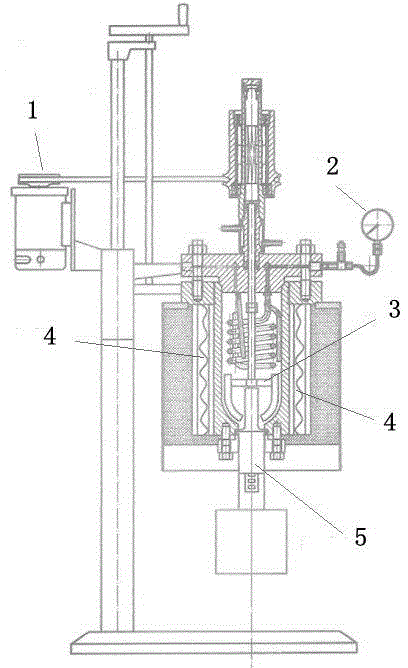

[0022] (3) Pour the mixed solution of lithium cobaltate waste and lithium hydroxide solution into the ultrasonic reactor, the volume of the mixed solution is 0.7L, and then add the oxidant (30% H 2 o 2 Solution) 50Ml; and quickly seal the ultrasonic reactor, the reactor is equipped with an electric heating device, a stirring device, a temperature control device, a water flow cooling device, and an ultrasonic horn is installed at the bottom of the reactor;

[0023] (4) The power of the ultrasonic equipment is 750W, the ultrasonic frequency is 25...

Embodiment 2

[0028] (1) Select the discarded lithium-ion battery, discharge it and disassemble it to obtain the positive electrode aluminum foil;

[0029] (2) Put the positive electrode aluminum foil into a muffle furnace and calcinate at 420°C for 2.2 hours. After the temperature drops, shake the burned aluminum foil to make lithium cobalt oxide fall off from the current collector aluminum foil to obtain black lithium cobalt oxide powder

[0030] (3) Pour the mixed solution of lithium cobalt oxide waste and lithium hydroxide solution into an ultrasonic reactor, the volume of the mixed solution is 0.7L, and the reactor is equipped with an electric heating device, a stirring device, a temperature control device, and a water flow cooling device, and Install an ultrasonic horn at the bottom of the reactor;

[0031] (4) The power of the ultrasonic equipment is 820W, the ultrasonic frequency is 25 kHz, heated in a closed autoclave at a constant temperature of 120°C, and ultrasonic radiation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com