Method for strongly leaching laterite-nickel ore at normal pressure by using sulphuric acid

A laterite nickel ore, enhanced leaching technology, applied in the direction of improving process efficiency, etc., can solve the problems that the process technology has not been popularized and applied, the nickel leaching rate is not high enough, and the leaching residual acid is high, and achieves complete leaching reaction, strong corrosiveness, Highly reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

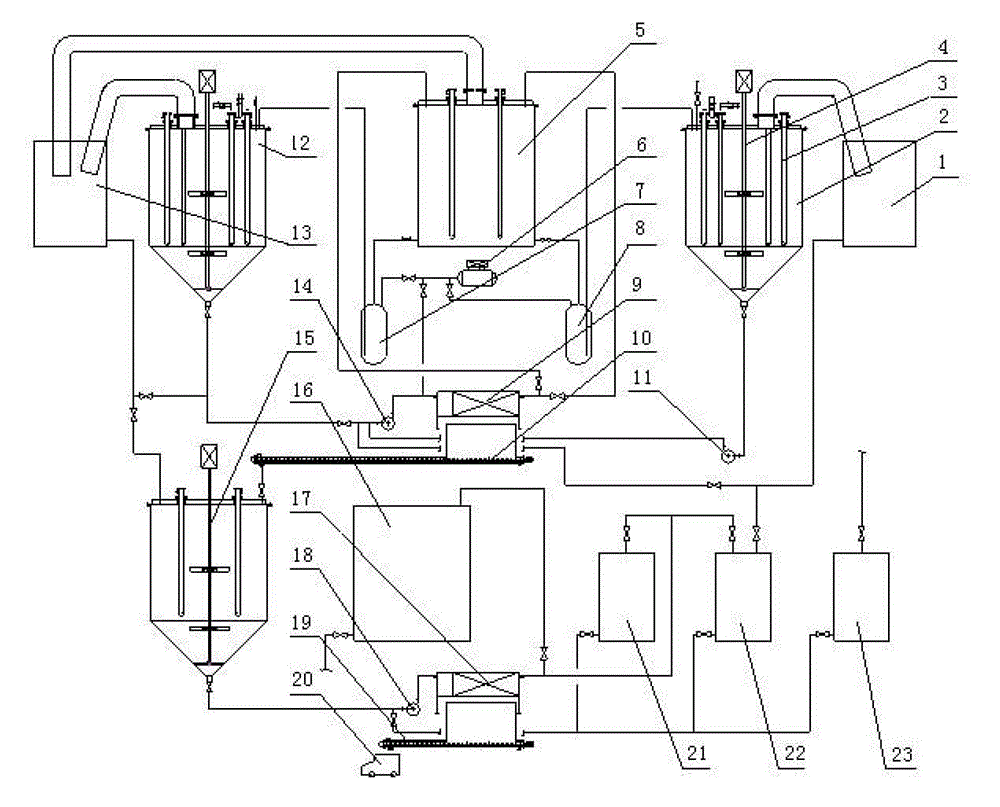

Image

Examples

Embodiment 1

[0024] The laterite nickel ore imported by a certain unit contains Ni 1.4Wt% on average, take a small amount of grinding at random, get 50 grams of the above-mentioned laterite nickel ore and grind it to -100 mesh, use 200ml water to mix, add 250ml concentrated sulfuric acid under stirring, at this time When the temperature reaches 120°C, control the temperature rise to 150°C, and maintain the reaction for 30 minutes. At this time, the liquid level line is 330ml, and the leaching liquid-solid ratio is 6:1. Cool down to 80°C, filter, and rinse to obtain 270ml of filtrate and 100ml of eluent. 25 grams of leaching residue after drying, containing Ni 0.006wt%, containing SiO 2 79.99wt%, raw ore contains Ni 1.40wt%, Ni leaching rate 99.8wt%.

Embodiment 2

[0026] Get 50 grams of the same laterite nickel ore as in Example 1, add 100 ml of the eluent of Example 1 to adjust the slurry, add 100 ml of concentrated sulfuric acid, then add all the filtrate in Example 1, heat up to 160 ° C, and maintain it for 45 minutes. When the liquid level line was 430ml, the leaching liquid-solid ratio was 8.5:1, cooled to 80°C and filtered, the filtrate and eluent were not measured, and finally obtained 24 grams of dried leaching residue, containing Ni 0.006wt%, containing SiO 2 81.50wt%, Ni leaching rate 99.8wt%.

Embodiment 3

[0028] Adopt the same source of laterite nickel ore as in Example 1, randomly take about 1 kg and grind it to ≤100 mesh, then analyze several elements such as nickel and cobalt, and in embodiment 3, take 400 grams of the above-mentioned finely ground laterite nickel ore, add water 1000ml to adjust Slurry, add concentrated sulfuric acid 1500ml, heat up to 160°C, at this time, the liquid level line is 2000ml, the calculated liquid-solid ratio of leaching is 4.5:1, maintain for 40 minutes, cool down to 90°C and filter, and obtain 1300ml of leaching mother liquor and 1200ml of eluent. Finally, the dry weight of the leached residue was 190 grams. The content of each element in the leaching slag and the results of the leaching rate are shown in Table 1.

[0029] Table 1 Example 3 The content of each element in the leaching slag and the results of the leaching rate

[0030] the element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com