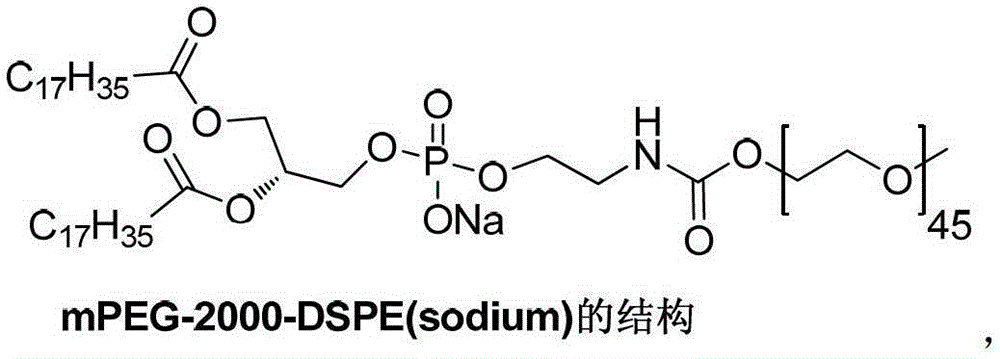

A kind of preparation method of mpeg2000-dspe sodium salt

A technology of sodium salt and compound, applied in the field of preparation of mPEG2000-DSPE sodium salt, can solve the problems of difficult purification, difficult industrial production, many side reactions, etc., so as to reduce the reaction risk and cost, and reduce the generation and reaction of impurities. Highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

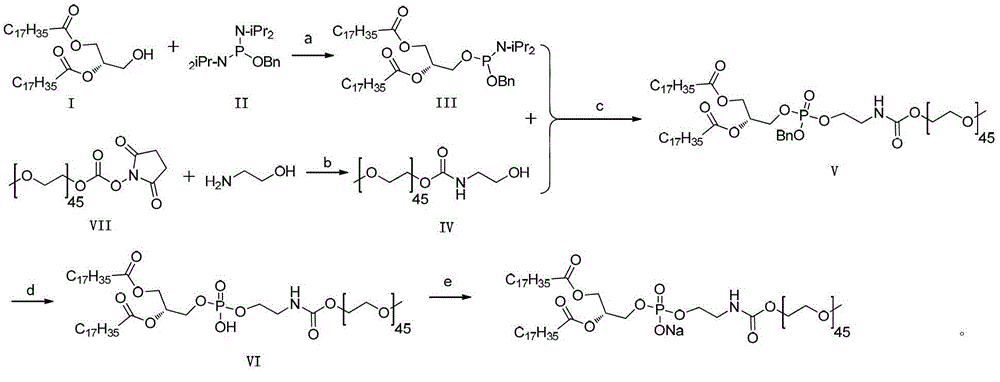

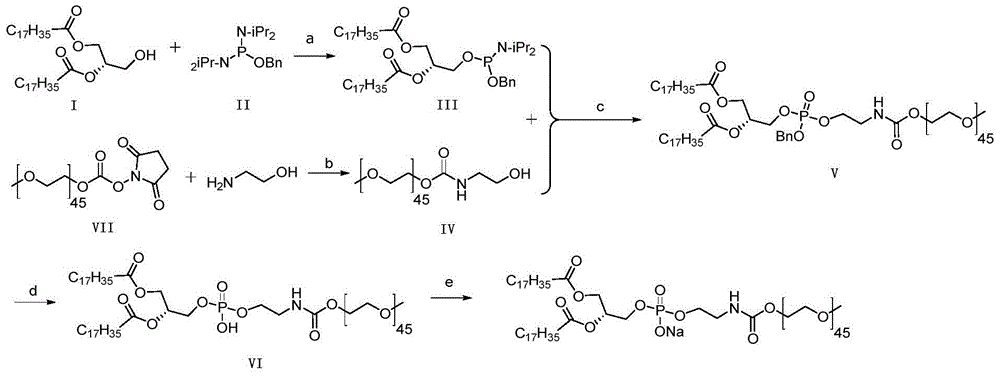

[0027] Embodiment 1. The preparation of compound compound IV:

[0028] Dissolve 0.73g of ethanolamine in 100ml of chloroform, and slowly add 21.5g (0.01mol) of mPEG-2000-Su (compound VII) 100ml of chloroform solution to the above reaction solution dropwise at room temperature, after the addition is complete, stir at room temperature for reaction 4 -6 hours; the reaction solution was evaporated to dryness, 200 ml of n-hexane was added to the residue, beating at room temperature for 1 hour, suction filtration, and the filter cake was recrystallized with ethyl acetate to obtain 18.5 g of white solid, TLC (GF254) single spot.

[0029] 1 HNMR (500Hz, DMSO-d6): 4.20-4.30 (m, 2H), 3.50-3.84 (m, 180H), 3.30-3.45 (m, 3H).

Embodiment 2

[0030] Embodiment 2. Preparation of compound compound V:

[0031] Dissolve 62.5g (0.1mol) of compound I in 1500ml of dichloromethane, cool down to 0-5°C, and under the protection of argon, slowly add 33.8g (0.1mol) of compound II and 1-H-tetra Nitrazole 7g (0.1mol), temperature control 0-5 ℃ stirring reaction for 2-4 hours; under the above reaction conditions, add 204g (0.1mol) compound IV and 1-H-tetrazolium to the above reaction solution in sequence 7g (0.1mol), temperature controlled at 0-5°C and stirred for 2-4 hours; the reaction solution was cooled to -20~-15°C, and mCPBA (m-chloroperoxybenzoic acid) 304g (0.15 mol), temperature controlled and stirred for 30 minutes; lower the temperature of the reaction solution to -30~-20°C, slowly add 12.6g (0.1mol) sodium sulfite / 30ml purified aqueous solution dropwise to the reaction solution, and naturally rise to room temperature and stir for 45 minutes Starch-KI test paper test reaction solution does not turn blue, the reaction ...

Embodiment 3

[0034] The preparation of embodiment 3.MPEG-2000-DSPE (non sodium):

[0035] Compound V refined product 28.7g (0.01mol) is dissolved in 287ml dehydrated alcohol, adds 5% palladium carbon 2.87g (10%) and solid ammonium carbonate 2.88g (0.03mol) successively in the reaction solution, temperature control 25- Stir and react at 40°C for 4-6 hours, filter to remove solid insoluble matter, cool the filtrate to 0-5°C to crystallize, filter with suction, wash the filter cake with cold absolute ethanol, and dry under vacuum at room temperature to obtain 23.5g of white solid, TLC (GF254) single point.

[0036] 31 PNMR (500Hz, D2O): 2.345

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com