Preparation method of hydrogel patch substrate with gradient drug concentration

A technology of drug concentration and hydrogel, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, and pharmaceutical formulas, which can solve the problem of high initial investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

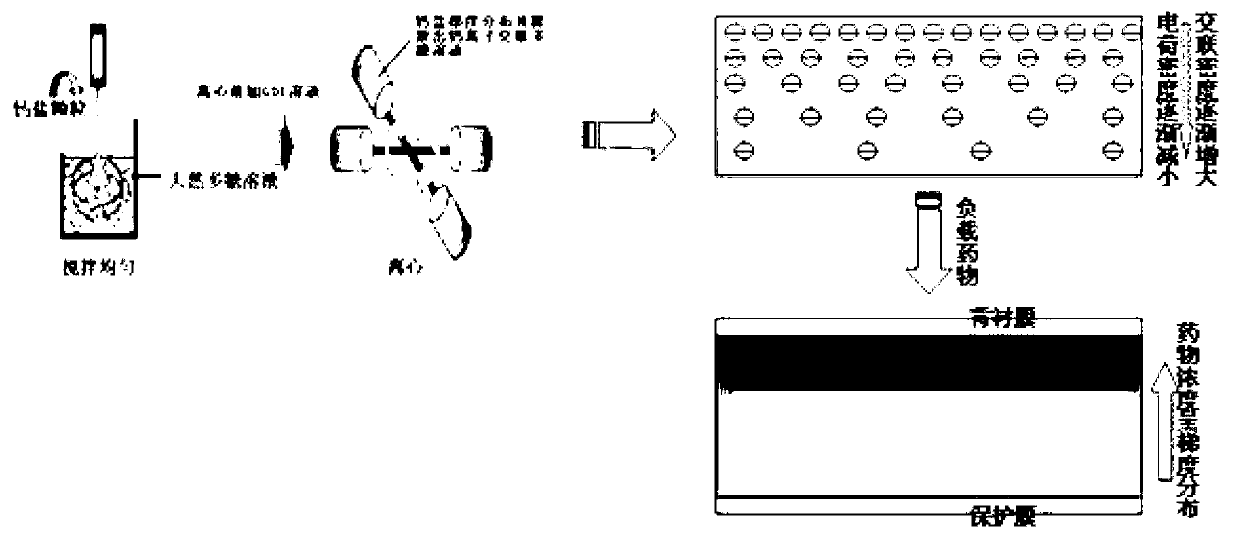

[0030] S1. Prepare a solution of sodium alginate (sodium alginate, product number S100126) with a concentration of 1%, add dry micron-sized hydroxyapatite powder (0.0137g hydroxyapatite per 10ml polysaccharide solution) and stir evenly until it becomes milky white The suspension is poured into a cylindrical mold of required shape, and the mold is put into a constant temperature and humidity chamber at 25°C to maintain a constant temperature;

[0031] S2. In the mould, add the mol ratio of calcium ion in the calcium salt to be the existing gluconolactone solution of 4:5, stir evenly,

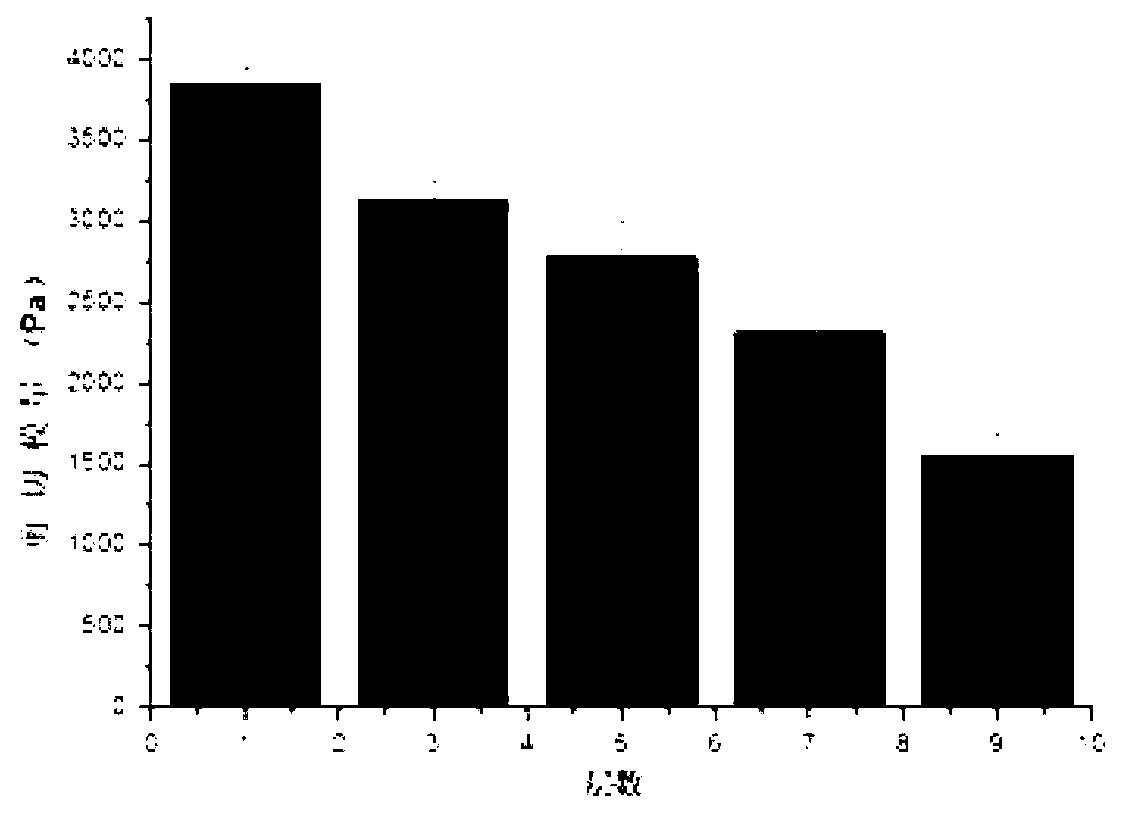

[0032] S3. Put it into a centrifuge with temperature control at 25°C, centrifuge at a centrifugal speed of 4500r / min for 40min, and let stand to obtain a hydrogel.

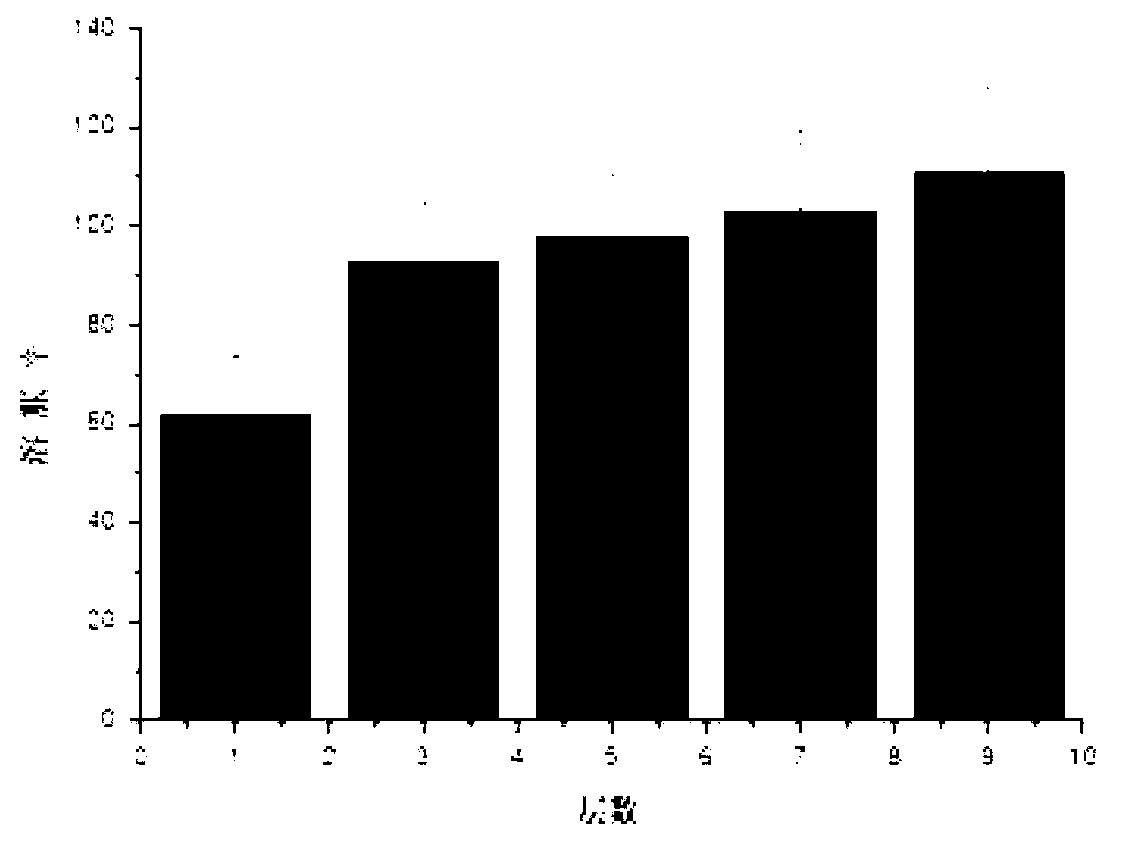

[0033] S4. Remove the hydrogel and soak it in 25ug / ml methylene blue for 24 hours to complete drug gradient loading.

Embodiment 2

[0035] S1. Prepare a solution of sodium alginate (sodium alginate, product number S100126) with a concentration of 5%, add dry nano-scale calcium carbonate powder (0.0274g calcium carbonate per 10ml polysaccharide solution) and stir evenly, pour it into the required shape in the star mold;

[0036] S2. In the mould, add the freshly dissolved gluconolactone solution that the mol ratio of calcium ion in the calcium salt is 4:5, stir well,

[0037] S3. Put it into a centrifuge, centrifuge at a centrifugal speed of 2500r / min for 15min, and let it stand to obtain a hydrogel.

[0038] S4. The hydrogel was removed from the mold and soaked in 2 mg / ml colchicine for 18 hours to complete drug gradient loading.

Embodiment 3

[0040] S1. Prepare a natural polysaccharide solution of sodium carboxymethylcellulose (sodium carboxymethylcellulose, product number C104979) with a concentration of 3%, and add dry nano-sized hydroxyapatite powder (0.0274g hydroxyl apatite per 10ml polysaccharide solution) Apatite) Stir evenly, pour into the cuboid mold of required shape;

[0041] S2. In the mould, add the freshly dissolved gluconolactone solution that the mol ratio of calcium ion in the calcium salt is 4:5, stir well,

[0042] S3. Put it into a centrifuge, centrifuge at a centrifugal speed of 2500r / min for 30min, and let it stand to obtain a hydrogel.

[0043] S4. Remove the hydrogel and soak it in 2 mg / ml sodium sulfadiazine for 36 hours to complete drug gradient loading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com