Preparation method of composite positive pole material for lithium sulphur battery

A composite cathode material, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increased transmission impedance of carbon materials, low sulfur content of composite materials, slow volatilization process, etc. The effect of electrical conductivity and fast diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

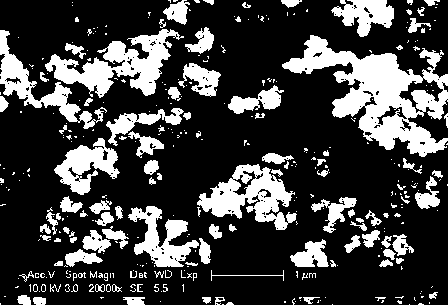

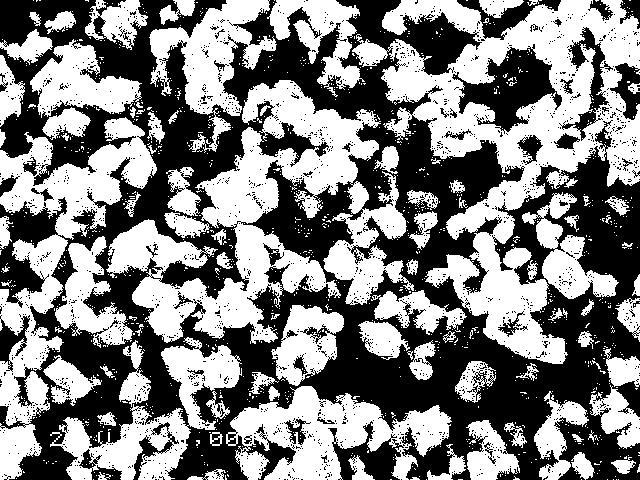

Image

Examples

Embodiment 1

[0028] Take 4g of potassium hydroxide and 2g of melamine and add them to 1g of charcoal airgel at the same time, mix well, pour into a nickel crucible, place in a muffle furnace and heat to 800°C under an inert atmosphere of argon or nitrogen, and keep it warm for 2 hours. The obtained solid was washed with dilute sulfuric acid solution, then washed with distilled water or ethanol until neutral, and dried at 120°C to obtain a carbon airgel material modified by activation + nitrogen doping synchronous process. The specific surface area of the modified carbon airgel is increased from that of the unmodified 620 m 2 / g increased to 1958m 2 / g, pore volume from 0.34 cm 3 / g increased to 0.67cm 3 / g, the nitrogen doping amount reaches 15.8at%.

[0029] At room temperature, 2 g of elemental sulfur was dissolved in 40 g of carbon disulfide organic solvent to form an organic sulfur solution with a sulfur content of 5%, and 0.37 g of modified carbon airgel material was slowly added,...

Embodiment 2

[0033] At room temperature, 2 g of elemental sulfur was dissolved in 10 g of toluene organic solvent to form an organic sulfur solution with a sulfur content of 20%, and 1.2 g of the modified carbon airgel material obtained according to the method of Example 1 was slowly added, and ultrasonically oscillated at room temperature for 1 hour. Then put the solution into the extraction kettle, use supercritical propylene fluid as the extraction agent to carry out anti-solvent crystallization extraction, the extraction temperature is 150°C, the pressure is 28MPa, the time is 50 minutes, and the flow rate of the supercritical fluid is 500 ml / min; Separation under reduced pressure, the separation pressure is 4MPa, the separation temperature is 45°C, and then rinsed with ethanol eluent. After vacuum drying at 60°C, a carbon airgel-sulfur cathode composite material modified with a sulfur content of 58.4% was obtained.

Embodiment 3

[0035] At room temperature, 2 g of elemental sulfur was dissolved in 40 g of benzene organic solvent to form an organic sulfur solution with a sulfur content of 5%, and 0.23 g of the modified carbon airgel material obtained according to the method of Example 1 was slowly added, and ultrasonically oscillated at room temperature. Then the solution is put into the extraction kettle, and the anti-solvent crystallization extraction is carried out with supercritical cyclohexane fluid as the extraction agent. The extraction temperature is 300° C., the pressure is 30 MPa, the time is 55 minutes, and the flow rate of the supercritical fluid is 900 ml / Minutes; separated under reduced pressure, the separation pressure is 5 MPa, the separation temperature is 40 ° C, and then rinsed with ethanol eluent. After vacuum drying at 60°C, a carbon airgel-sulfur cathode composite material modified with a sulfur content of 88.9% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com