Rare earth catalyst for polymerization of butadiene, and preparation and application methods thereof

A technology of rare earth catalyst and butadiene, which is applied in the field of rare earth catalyst for butadiene polymerization and its preparation and application, which can solve the problems of low activity, difficult control of product molecular weight, distribution, monomer conversion rate, and difficult separation of aromatics and other problems, to achieve the effect of stable phase state, easy monomer conversion rate, and short monomer initiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

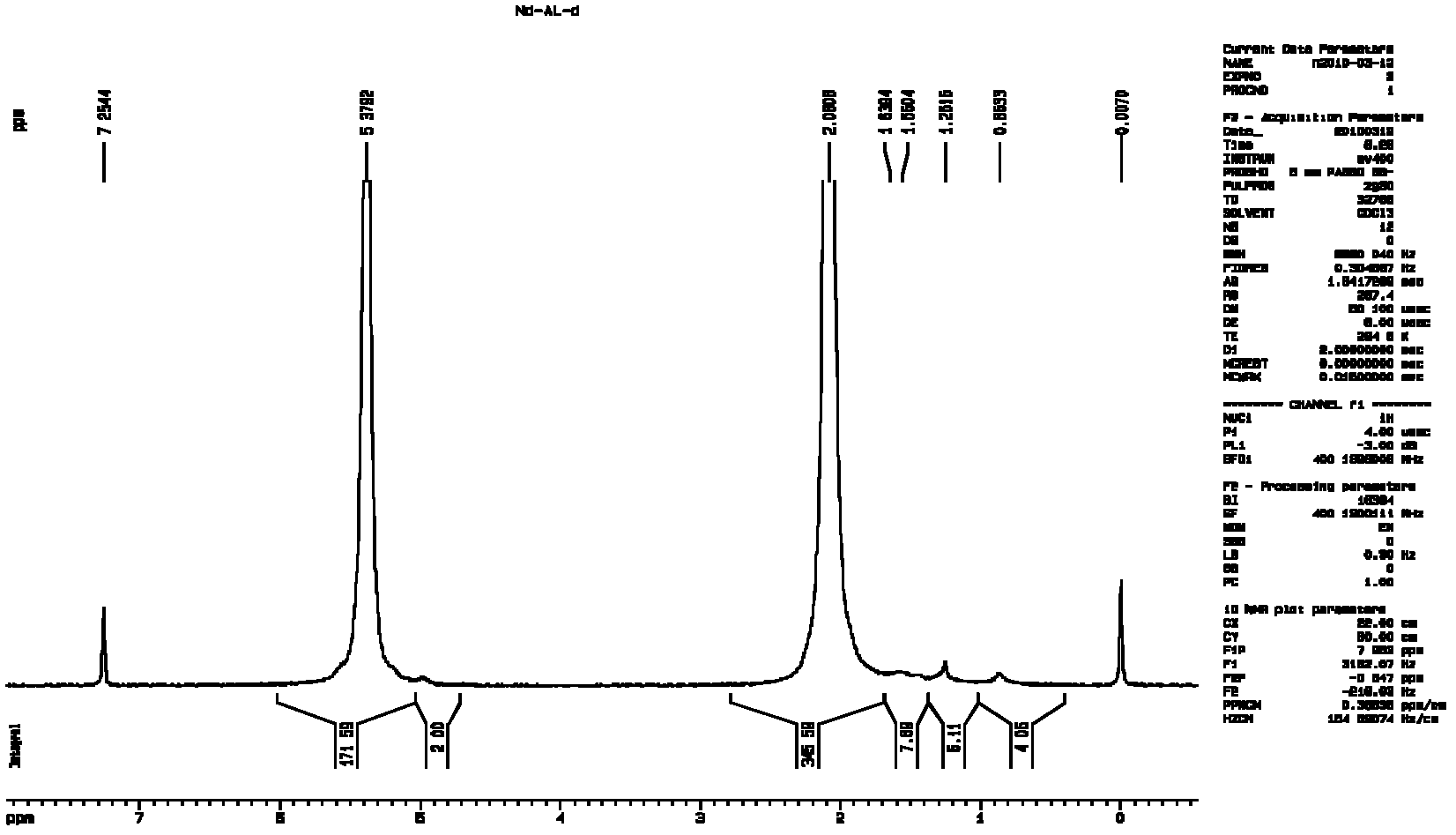

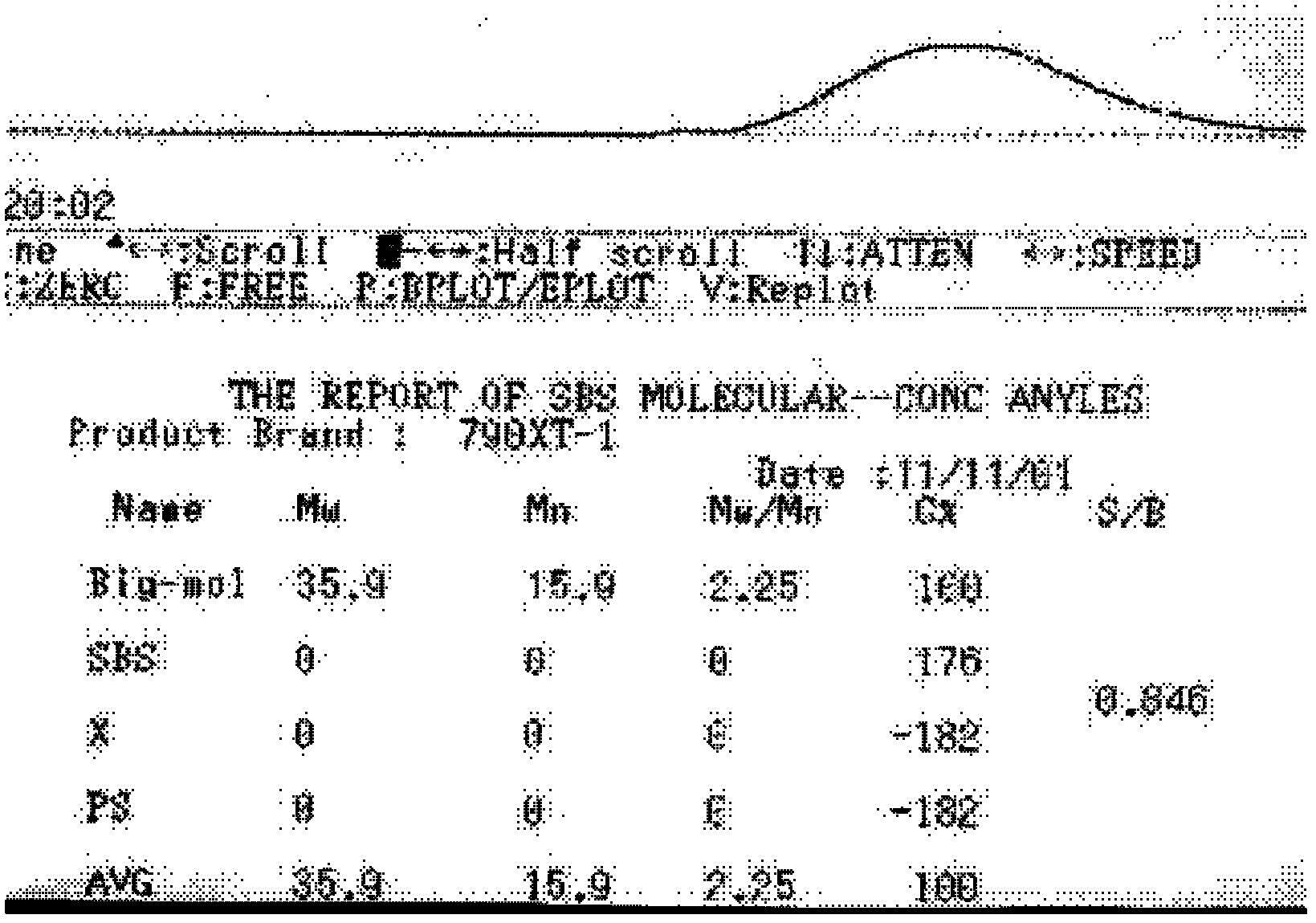

Method used

Image

Examples

Embodiment 1

[0029] Under the protection of nitrogen, 125ml neodecanoate (1.75mmol, the concentration of neodymium is 0.014mol / L), 19.5ml of diisobutyl aluminum hydride (17.5mmol, the concentration of 0.9mol / L ), diethylaluminum chloride 2.2ml (1.75mmol), p-phenylene ether (0.150mmol) hexane solution, mixed uniformly, after aging for 30min at 25°C, a transparent homogeneous prepolymer active center catalyst solution was obtained .

[0030] Under nitrogen protection, add 2.5L of hexane solvent and 400ml of butadiene to a 5-liter polymerization reactor at 0°C, then add 28.56ml of the above-mentioned catalyst solution, (neodymium / monomer=0.136mmol / 100g butadiene Diene) was started to stir for polymerization, the initiation time was 4 minutes, and after 3 hours of reaction, a hexane solution containing 0.5% by mass fraction of 2,6-di-tert-butyl-p-cresol was added to terminate the polymerization. The polymer glue was condensed with water vapor to remove the solvent and moisture, and then dried...

Embodiment 2

[0032] As described in Example 1, the other conditions are exactly the same, except that anisole is used instead of p-phenylene ether when the catalyst is prepared, the molecular weight distribution index of the product obtained is 2.45, and the cis-1,4-structural unit content reaches 97.1%. Mooney The viscosity was 60, and the yield of the polymerization product was 95.8%.

Embodiment 3

[0034] As described in Example 1, other conditions are exactly the same, except that p-phenylene ether is used instead of p-phenylene ether during catalyst preparation, the molecular weight distribution index of the obtained product is 2.38, the cis-1,4-structural unit content reaches 97.6%, Mooney The viscosity was 68, and the yield of the polymerization product was 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com