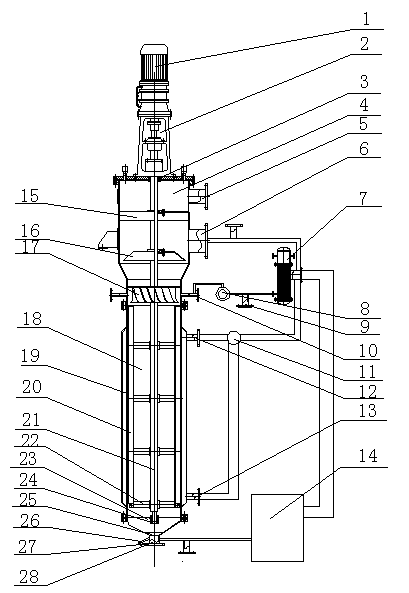

Compound centrifugal film evaporator and method for preparing high-purity soda ash-type copper carbonate

A thin film evaporator, copper carbonate technology, applied in separation methods, chemical instruments and methods, evaporation and other directions, can solve the problem that the product fineness and accuracy cannot meet market requirements, pressure changes increase production difficulties, and affect the yield of basic copper carbonate. rate and other issues, to achieve the effects of controllable production conditions, shortening production cycles, and avoiding the difficulty of manual cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity ≥ 99.9% as raw materials, the production process is as follows:

[0042] at 20m 3 pumped 15 meters into the concentrated ammonia water preparation tank with cooling coil 3 Deionized water, open the valve of the liquid ammonia steel cylinder, make the pressure of the liquid ammonia passing into the preparation tank be 0.2MPa, pass through the ammonia gas for 6 hours, prepare the concentrated ammonia water with a concentration of 135g / L, close the valve of the liquid ammonia steel cylinder; open the liquid ammonia located in the preparation tank The valve of the cooling water pipe in the medium but not connected with the concentrated ammonia water is fed with cooling water with a temperature of less than 15°C, and then the valve of the carbon dioxide steel cylinder is opened to control the pressure of the carbon dioxide introduced at 0.2MPa and the degree of carbonization at 80% to obtain carb...

Embodiment 2

[0046] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity ≥ 99.9% as raw materials, the production process is as follows:

[0047] at 20m 3 The strong ammonia water preparation tank with cooling coil, pumped into 15 meters 3 Deionized water, open the valve of the liquid ammonia steel cylinder, make the pressure of the liquid ammonia passing into the preparation tank be 0.15MPa, pass the ammonia gas for 7 hours, prepare the concentrated ammonia water with a concentration of 120g / L, close the valve of the liquid ammonia steel cylinder; open the liquid ammonia located in the preparation tank The valve of the cooling water pipe in the middle but not connected with the concentrated ammonia water is fed with cooling water with a temperature lower than 15°C, and then the valve of the carbon dioxide steel cylinder is opened, and the pressure of the carbon dioxide is controlled to be 0.15MPa, and the degree of carbonization is 100%, and the ammonium carbona...

Embodiment 3

[0051] Using standard cathode copper, liquid ammonia, and carbon dioxide with a purity ≥ 99.9% as raw materials, the production process is as follows:

[0052] at 20m 3 The strong ammonia water preparation tank with cooling coil, pumped into 15 meters 3 For deionized water, open the valve of the liquid ammonia steel cylinder, make the pressure of the liquid ammonia passing into the preparation tank be 0.1MPa, pass ammonia gas for 7 hours, and prepare concentrated ammonia water with a concentration of 85g / L, close the valve of the liquid ammonia steel cylinder; The valve of the cooling water pipe in the medium but not connected with the concentrated ammonia water is passed into the cooling water with a temperature of less than 15°C, and then the valve of the carbon dioxide cylinder is opened to control the pressure of the carbon dioxide introduced at 0.1MPa and the degree of carbonization at 140%. The amount of ammonium substance concentration is 3.5mol / L of carbonated ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com